LED lamp and heat radiation structure thereof

A technology of LED lamps and heat dissipation structures, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of increased volume and area, insufficient heat dissipation capacity, and inability to significantly reduce thermal resistance, etc. Achieve the effects of reducing thermal resistance, improving thermal conductivity and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

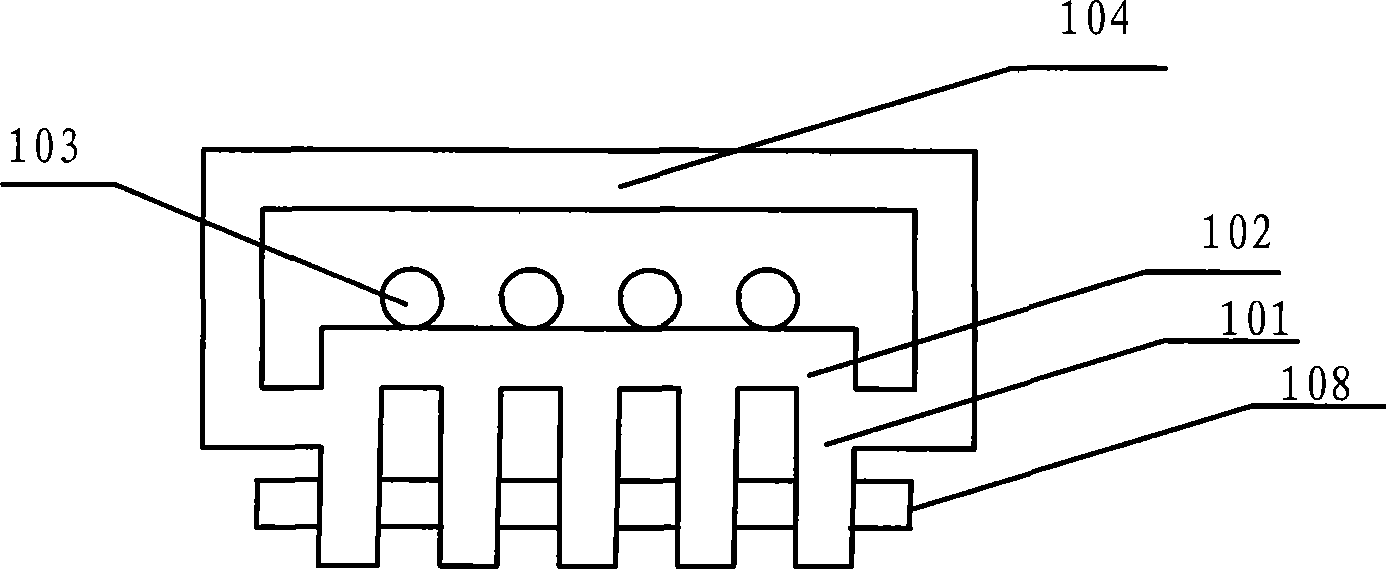

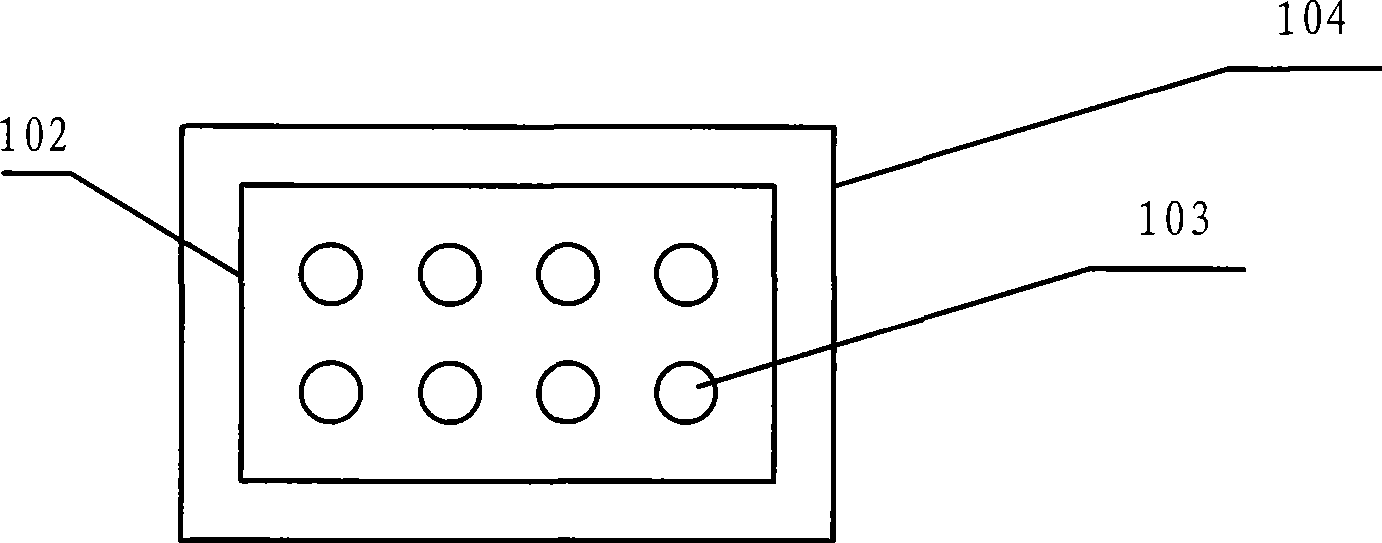

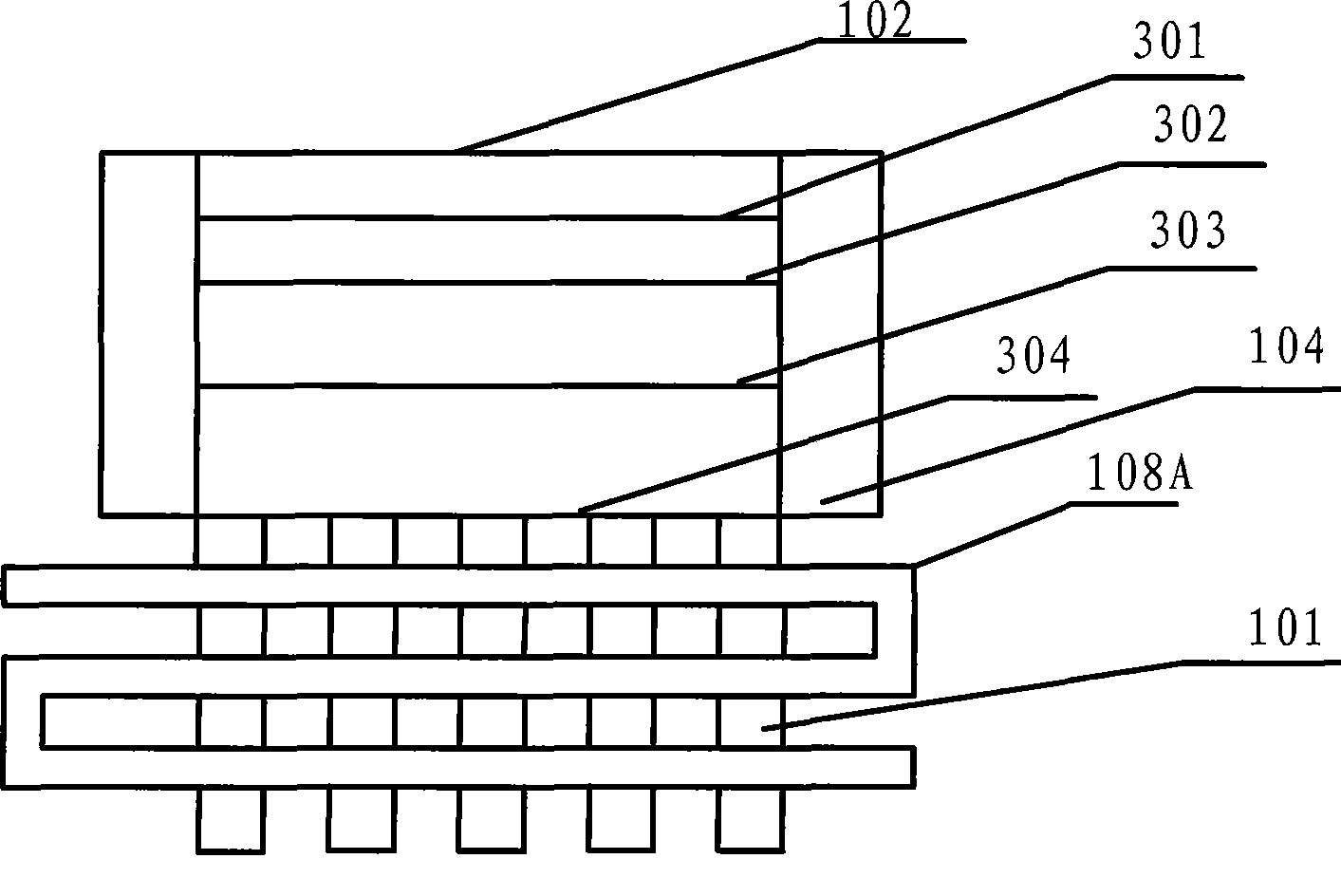

[0025] as attached figure 1 and figure 2 As shown, the present invention provides an LED lamp, which includes a lamp housing 104, a heat sink 101, a heat absorption tube 108, and a circuit board substrate 102. The heat sink 101 is fixed below the circuit substrate 102, and the circuit board substrate 102 is fixed inside the lamp housing 104; the lamp housing 104, the heat sink 101 and the circuit board substrate 102 are integrally formed of the same material; the heat absorption tube 108 is installed on the heat sink 101. The lamp housing 104, the heat sink 101 and the circuit board substrate 102 are integrated into one body, which is very conducive to the dissipation of heat; LED light-emitting diodes are fixed on the circuit board substrate 102, and other electronic components are connected to the circuit board substrate 102 by welding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com