LED lamp

A technology for LED lamps and lamp housings, which can be applied to the loss prevention measures of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., and can solve the problems of high cost, difficult heat dissipation characteristics, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

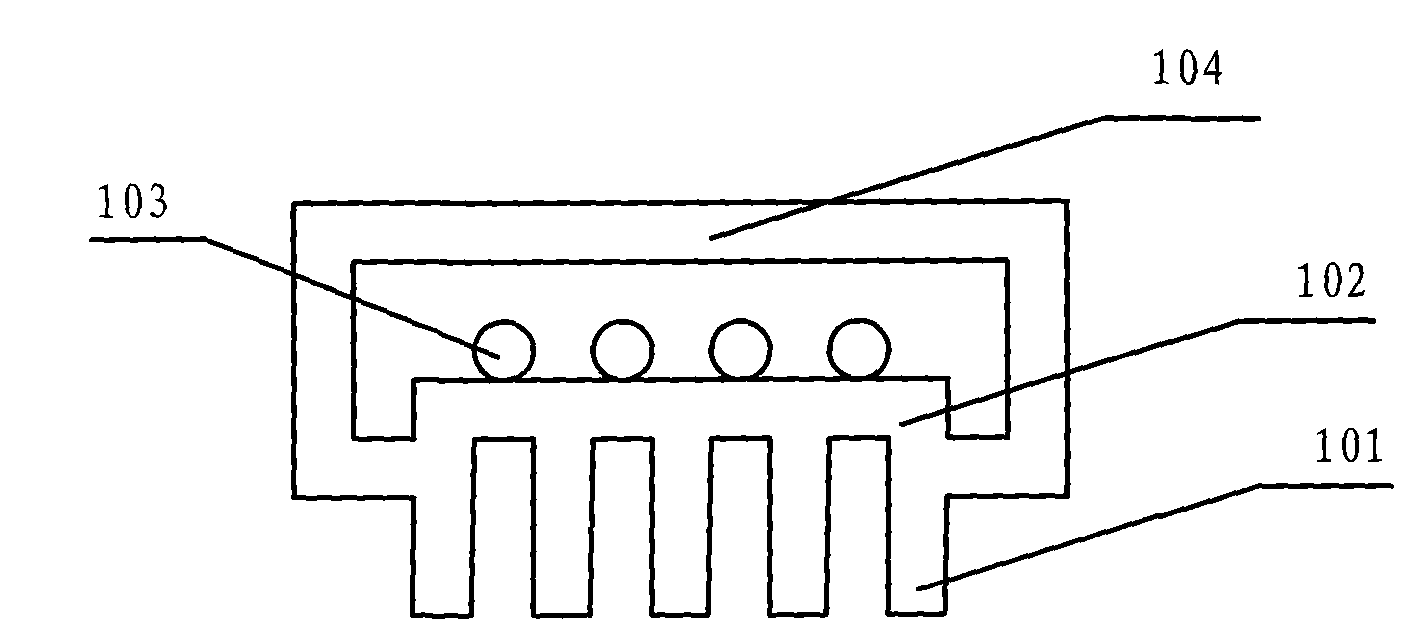

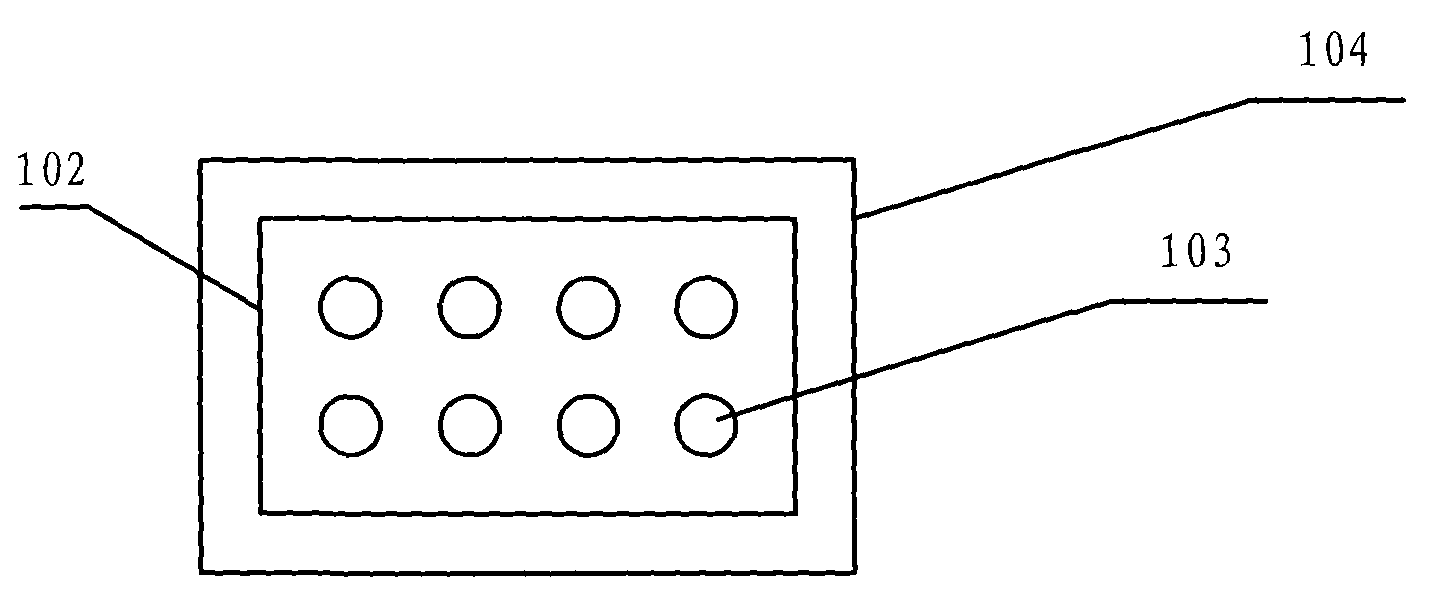

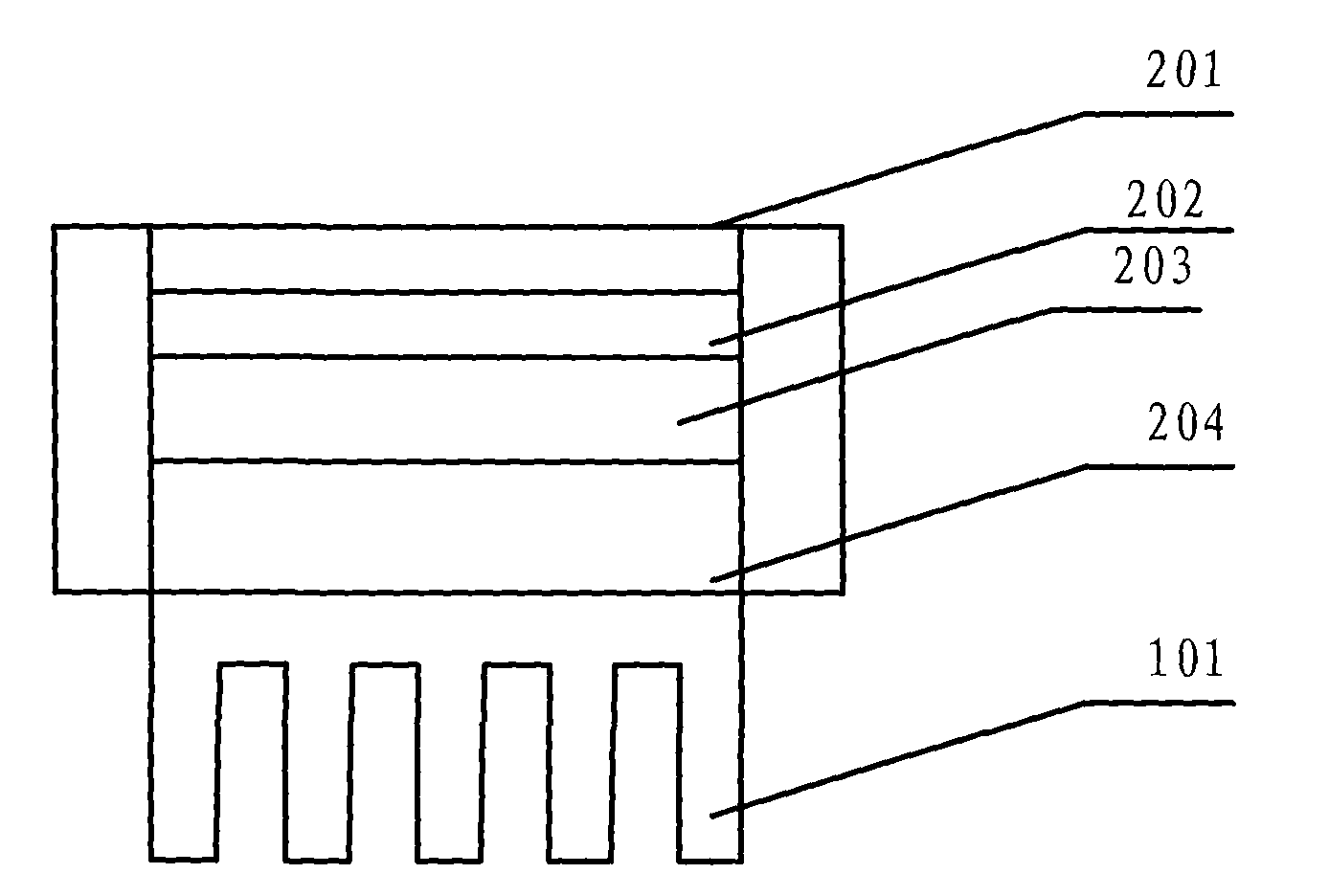

[0022] Such as figure 1 , figure 2 As shown, the present invention provides an LED lamp, which includes a lamp housing 104, a heat sink 101, a circuit board substrate 102, and an LED light-emitting diode 103. The heat sink 101 is fixed outside the lamp housing 104, and the circuit board substrate 102 It is fixed inside the lamp housing 104; the lamp housing 104, the heat sink 101 and the circuit board substrate 102 are integrally formed of the same material.

[0023] For example, copper composite materials, silver composite materials, aluminum composite materials or other alloy composite materials are used. The above various composite materials are formed by adding other different metal materials according to the properties of different metals and according to the needs of the design. They have very good heat dissipation and ductility.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com