Manufacturing process for high performance lignocellulosic fibre composite materials

A technology of lignocellulose and composite materials, which is applied in the field of lignocellulose fiber/thermoplastic composition with material characteristics, can solve the problems of easy breakage of glass fibers, hinder the utilization of the potential of composite materials, etc., and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

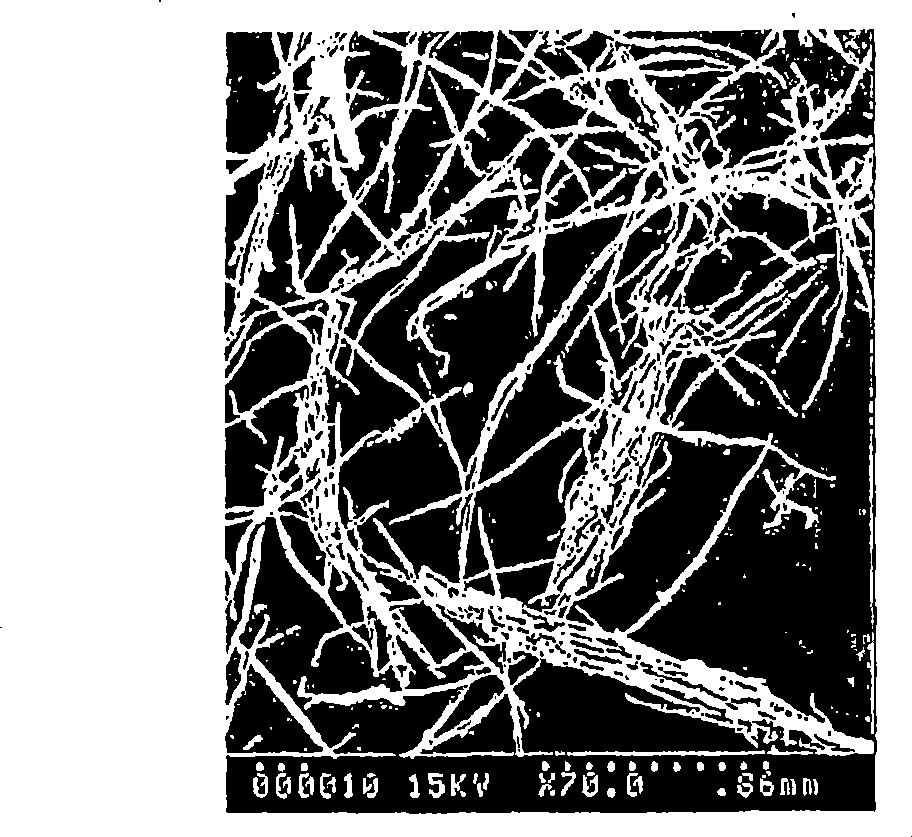

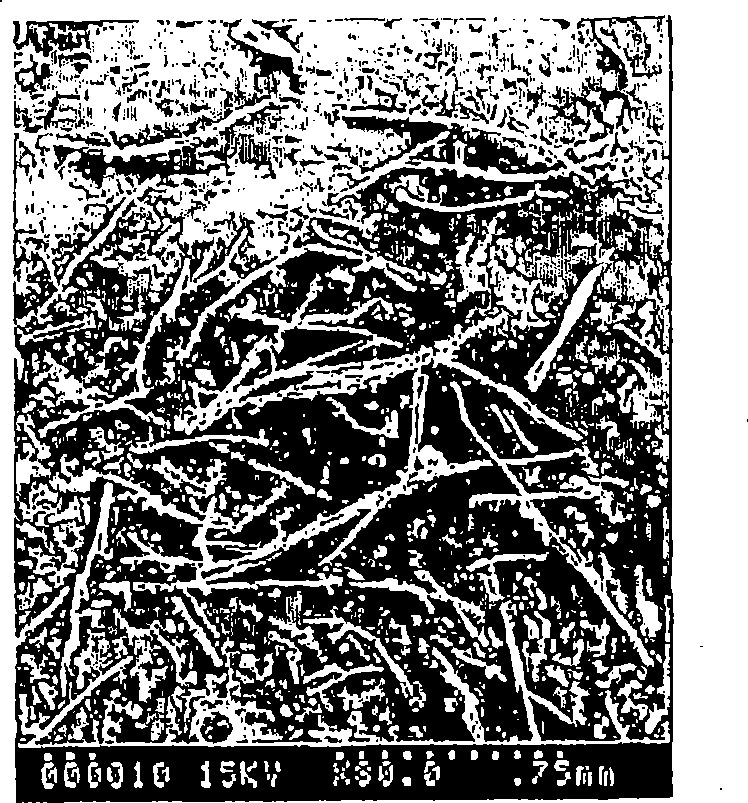

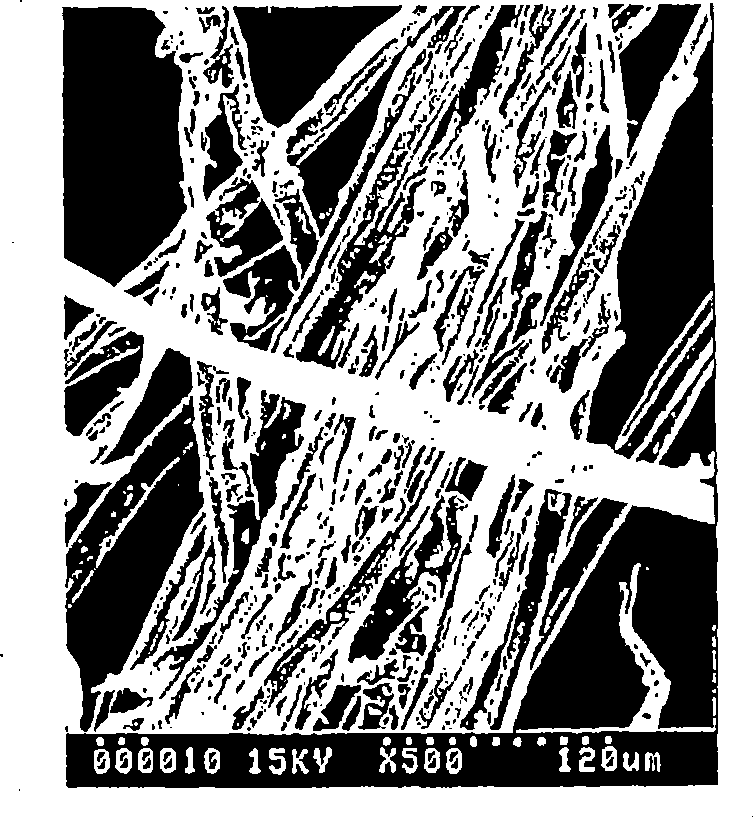

Image

Examples

Embodiment

[0084] The following examples illustrate some moldable thermoplastic compositions and composite products containing lignocellulosic fibers within the scope of the present invention and methods for their preparation. These are merely illustrative examples, and variations and modifications of the invention may be made by those skilled in the art without departing from the scope of the invention.

[0085] Properties of polypropylene

[0086] The properties of polypropylene are shown in Table 1 for comparison purposes.

[0087] ASTM test Properties ASTM D638 Tensile strength, MPa 31.6 ASTM D638 Tensile modulus, GPa 1.21 ASTM D790 Bending strength, MPa 50 ASTM D790 Flexural modulus, GPa 1.41

[0088] Table 1. Properties of polyolefins

[0089] thermoplastic composition

[0090] Examples of compositions of moldable thermoplastic compositions are given in Table 2. The pulp fibers are defibrillated in a high shear internal mixer fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com