Modelling pearl nucleus for pearl culture and preparation method thereof

A production method, pearl core technology, applied in the fields of application, fish farming, climate change adaptation, etc., can solve the problems of wearing out the mantle of pearl oysters, and achieve the effects of reducing breeding costs, beautiful appearance, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

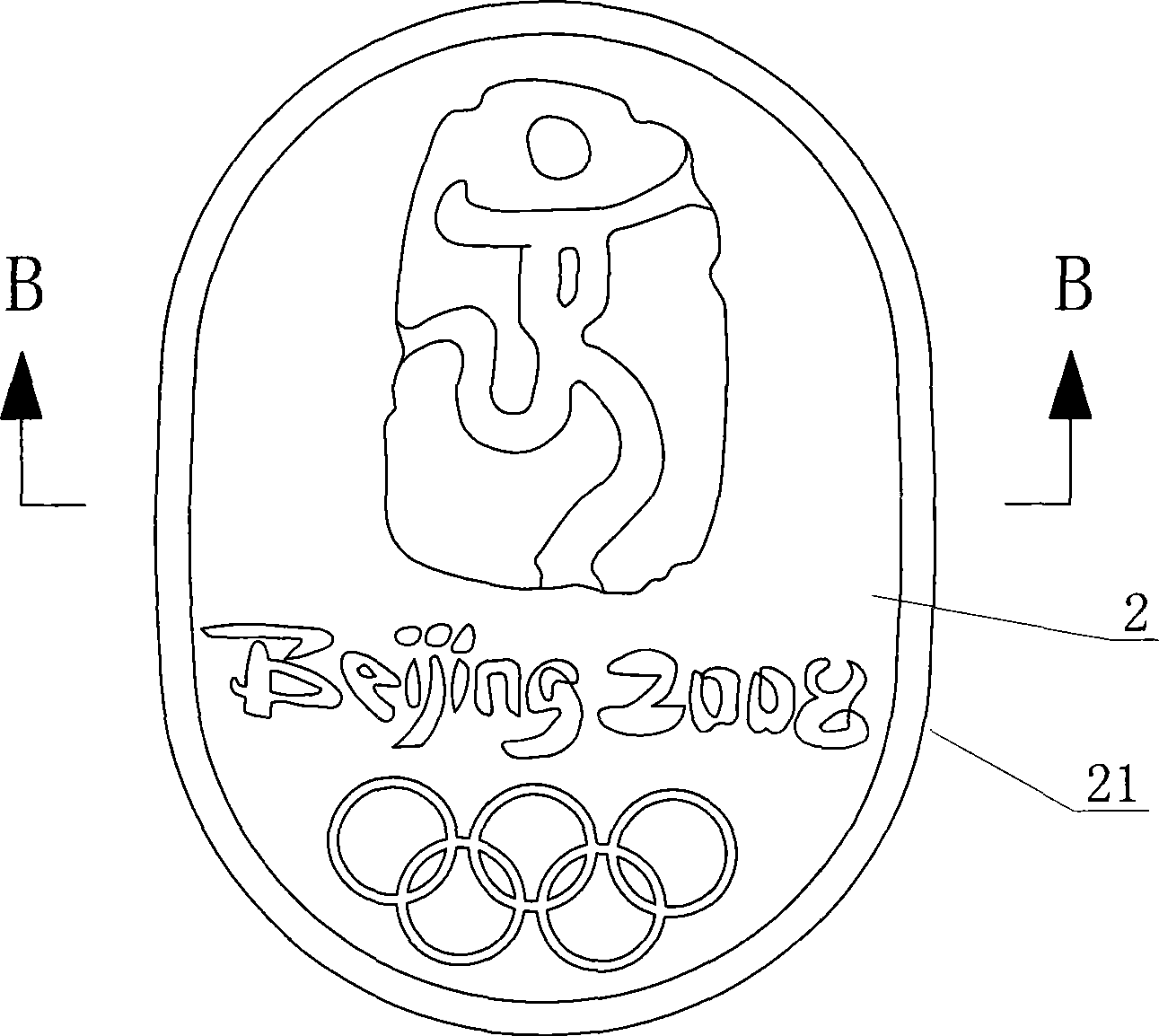

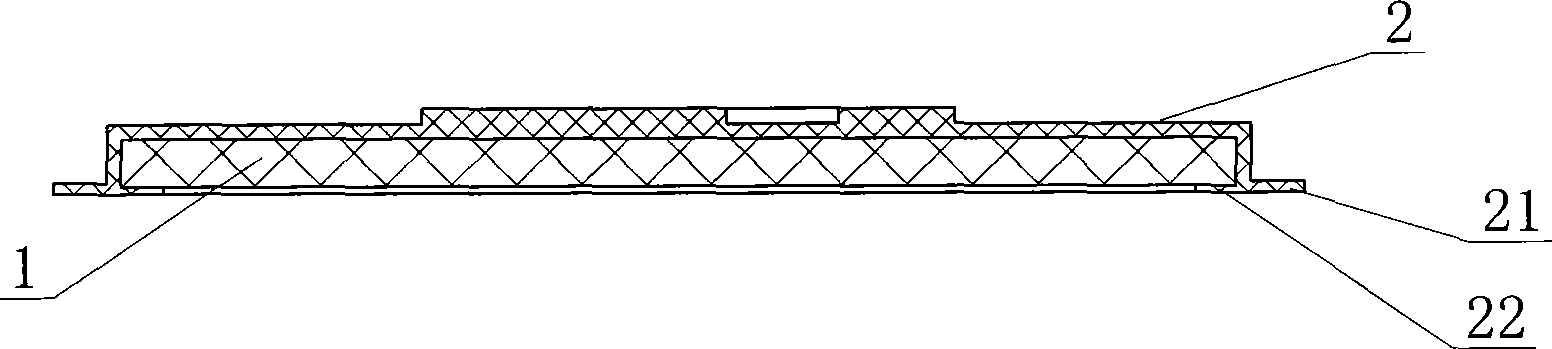

[0034] Embodiment one: as Figure 1-Figure 2 Shown, the preparation method of described molding pearl core comprises the following steps:

[0035] (1) First, make a molding iron mold, then put the refined silica gel material into the mould, press it on a machine tool at high temperature (generally 180°C-220°C) to form a soft molding outer mold 2 with an opening, and then Rinse with detergent and dry for later use;

[0036] (2), make mold inner mold iron mold, then form hard mold inner mold 1 through injection molding machine injection molding with hard plastic, then rinse and dry for subsequent use through detergent rinsing;

[0037] (3), put the hard molding inner mold 1 in step (2) into the soft molding outer mold 2 in step (1), that is, form a semi-enclosed composite molding pearl core, to provide nucleation and nurturing accessories Shell shaped pearls are used.

Embodiment 2

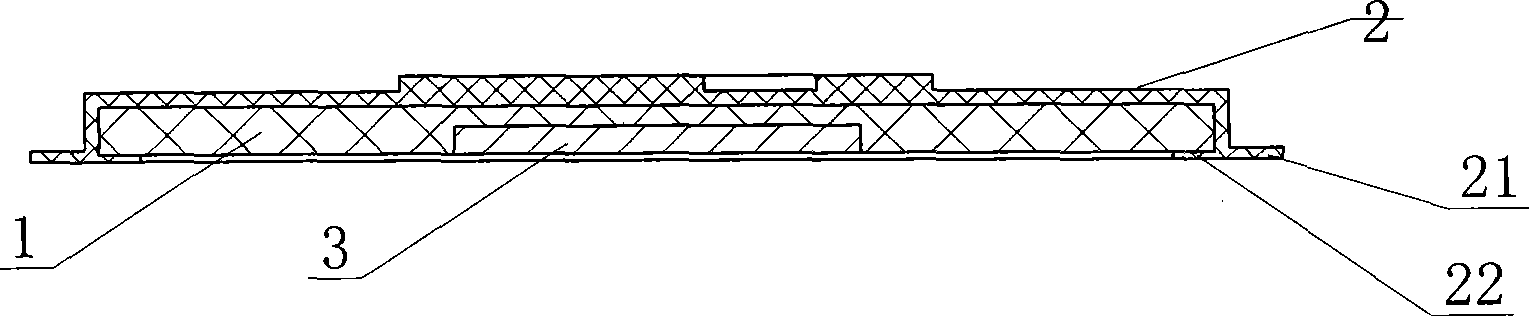

[0038] Embodiment two: as Figure 1-Figure 3 Shown, the preparation method of described molding pearl core comprises the following steps:

[0039] (1), first make a molding iron mold, then put the refined rubber material into the mould, press it on a machine tool at a high temperature (180°C-220°C) to form a soft molding outer mold 2 with an opening and a soft base edge 21, Then rinse with detergent and dry for later use;

[0040] (2), make the inner mold iron mold of the molding, then use hard plastic to form the inner mold 1 of the hard molding through injection molding machine injection molding, and then embed the magnet 3 in the inner mold 1 of the hard molding, and then rinse and dry with detergent spare;

[0041] (3), insert the hard molding inner mold 1 with magnet 3 in the step (two) into the soft molding outer mold 2 in the step (1), to form a semi-enclosed composite molding pearl core, to provide It is used to cultivate pearls with shells by planting nuclei.

Embodiment 3

[0042] Embodiment three: as Figure 4-Figure 5 The manufacture method of shown molding pearl core comprises the following steps:

[0043] (1), use hard materials, such as magnets, magnetic powder, etc. to make the inner mold 1 of the hard molding, and then the inner mold 1 of the molding is selected and qualified for decontamination and cleaning for subsequent use;

[0044] (2) Make a molding iron mold, then wrap the refined silica gel material into the hard molding inner mold 1 prepared above and put it into the mold together, press it on the machine tool at high temperature (180°C-220°C) to form a coated The all-inclusive composite molding pearl core of the soft molding outer mold 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com