Inkjet print head and manufacturing method thereof

An inkjet printing head and insulating layer technology, applied in printing and other directions, can solve the problems of reducing the reliability of the heater, heat accumulation, and increasing the input energy of the driving heater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

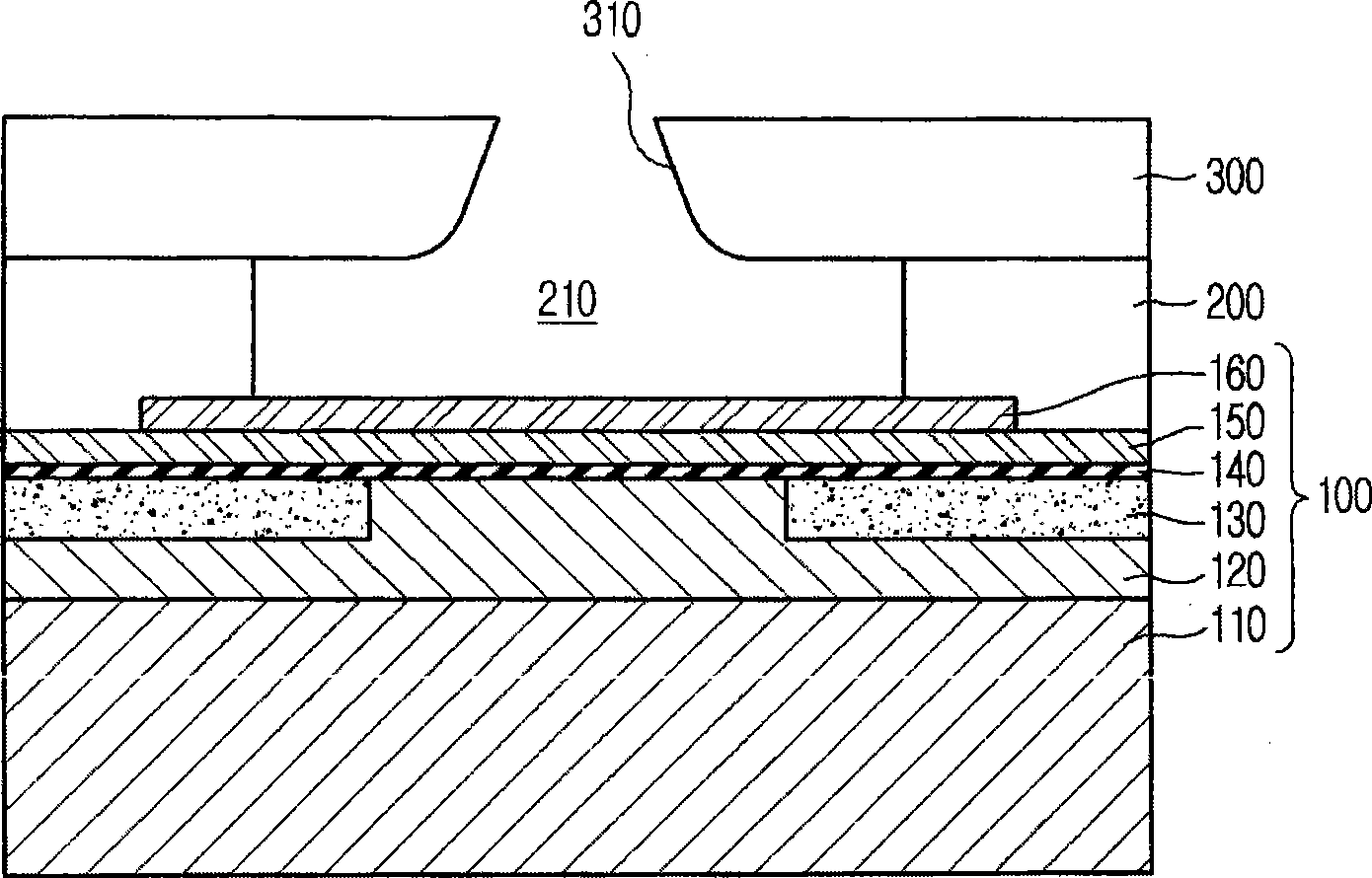

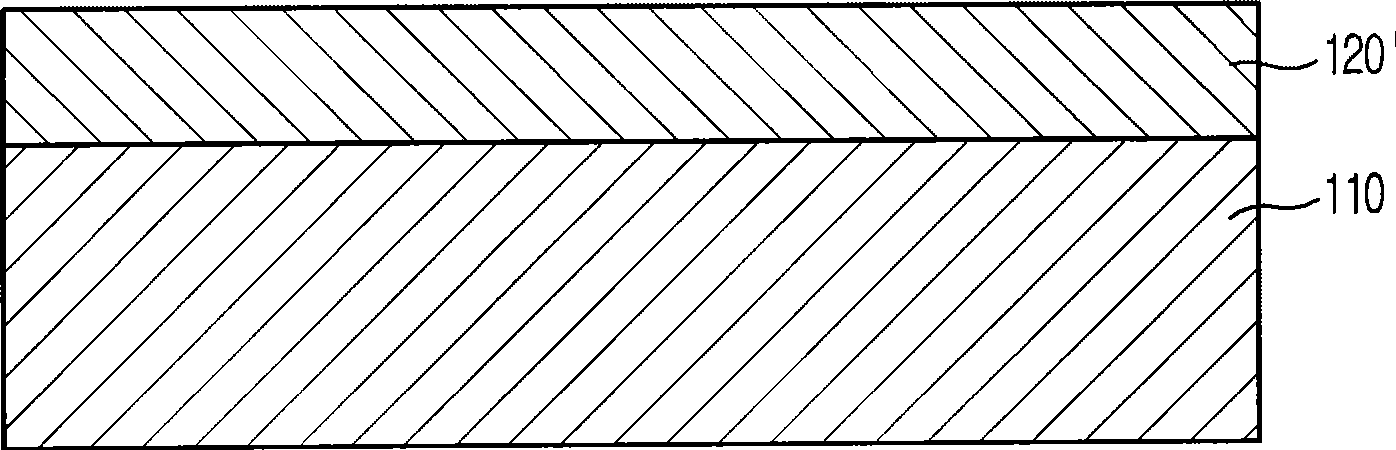

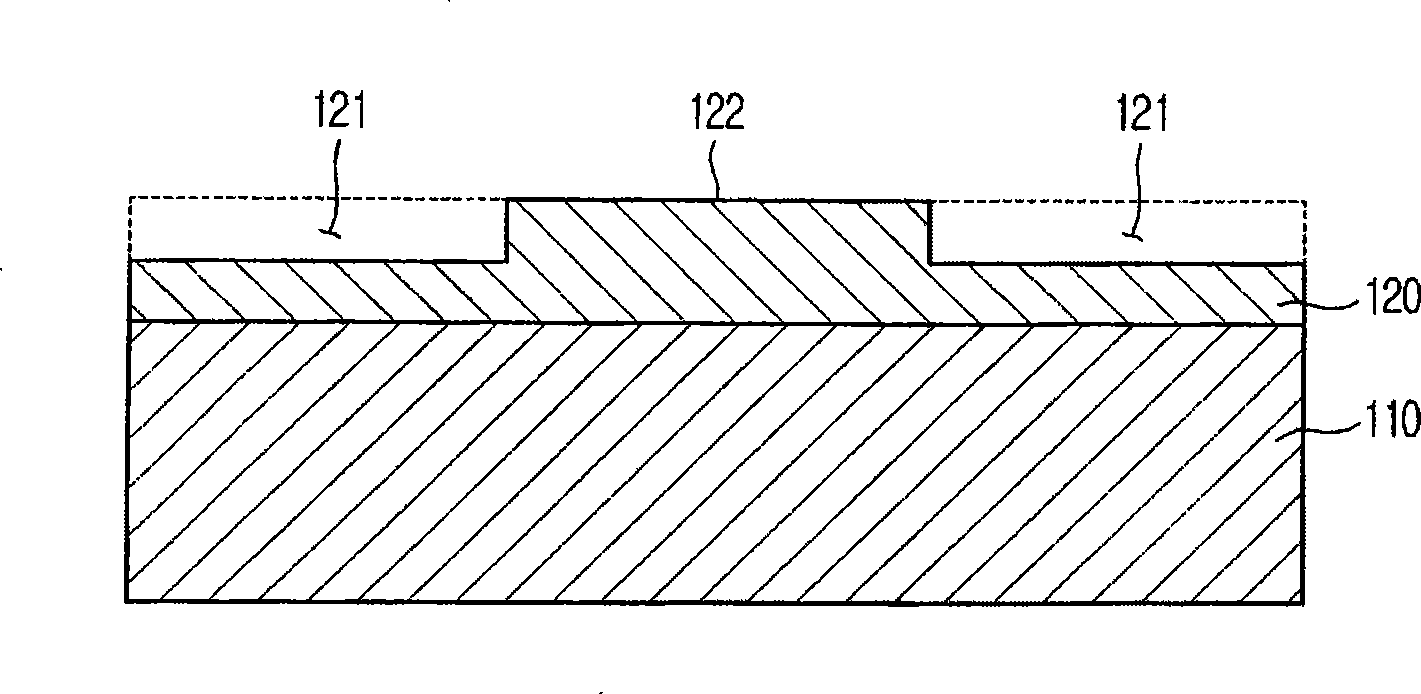

[0024] figure 1 is a cross-sectional view showing the structure of an inkjet printhead according to an embodiment of the present invention. Although only the unitary structure of the inkjet printhead is depicted in the drawings, a plurality of ink chambers and a plurality of nozzles are arranged in one or two rows in an inkjet printhead manufactured in a chip shape, and may also be arranged into three or more lines for better resolution.

[0025] Such as figure 1 As shown, the inkjet printhead manufactured acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com