Method for mending circulating pipe

A technology for circulating pipes and repairing materials, which is applied to pipe components, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as affecting production, affecting pipe age, tank age, and wasting costs, saving costs and reducing impregnation. Tube damage, the effect of increasing the average tube age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

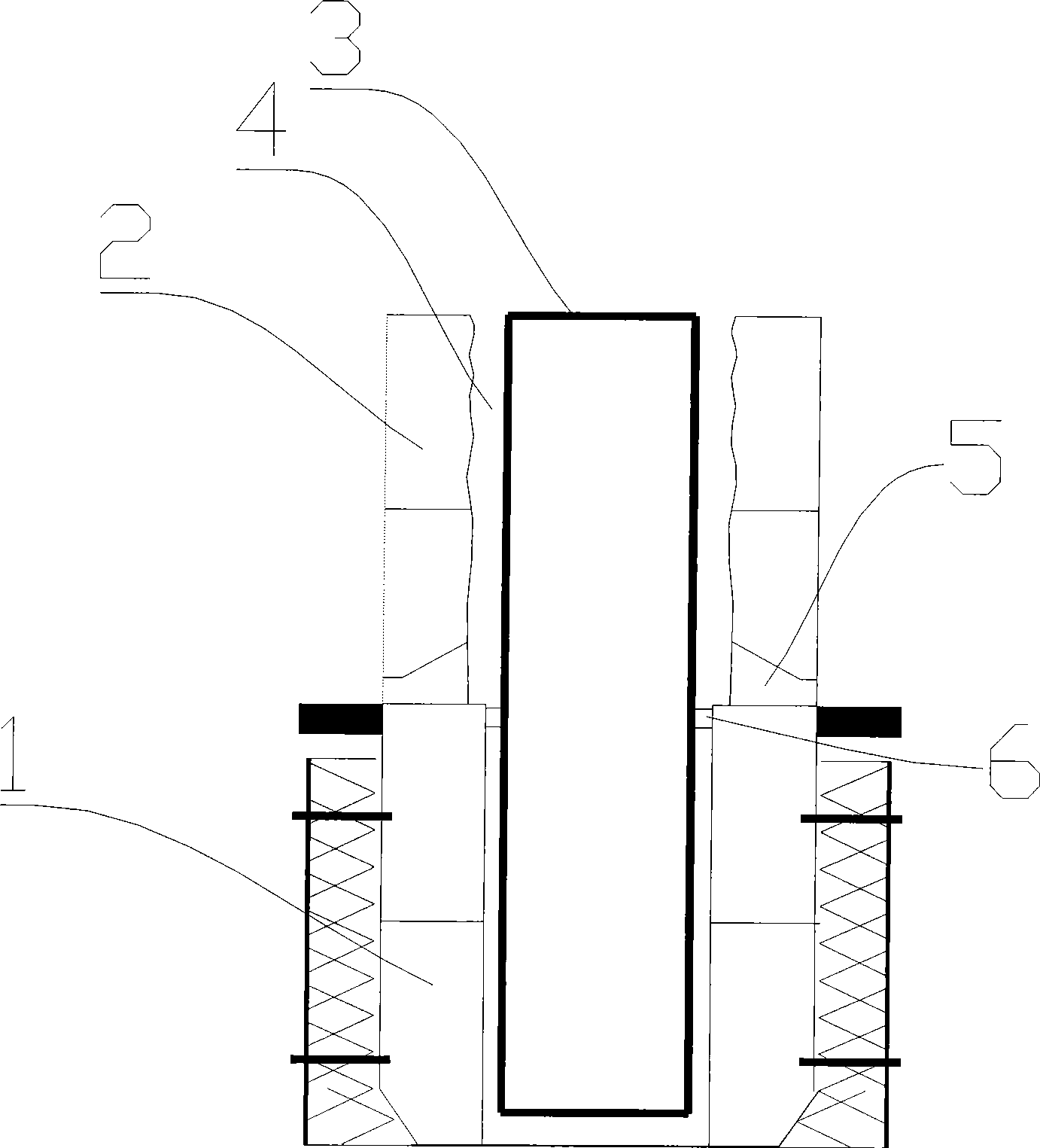

[0012] Such as figure 1 As shown, a method for repairing a circulation pipe, the lower end of the circulation pipe 2 is connected with an immersion pipe 1, and includes the following steps: A. Insert a steel drum 3 into the lumen of the circulation pipe 2 and the immersion pipe 1, and the steel drum 3 barrels There is a gap between the wall and the inner wall of the immersion pipe 1 and the inner wall of the circulation pipe 2; B. The gap between the steel drum 3 and the immersion pipe 1 is plugged with asbestos fiber 6; C. The repair material is 13-16 by weight: 100 is mixed and stirred into a fluid, and then the fluid repair material is pressed into the gap 4 between the barrel wall of the steel barrel 3 and the inner wall of the dip tube 1; D, the repair material is sintered by curing, natural evaporation and baking. The wall tiles falling off 5 of the circulation pipe 2 are filled with fire mud.

[0013] The method of the present invention was tested in Baosteel Company. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com