Steel truss tie bar arch bridge combined type tie bar

A tied-bar arch bridge and combined technology, which is applied in the field of tie-bars, can solve problems such as bar manufacturing, installation difficulties, poor structural integrity, and large bar cross-sections, and achieve the goals of reducing steel consumption, improving integrity, and reducing engineering costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

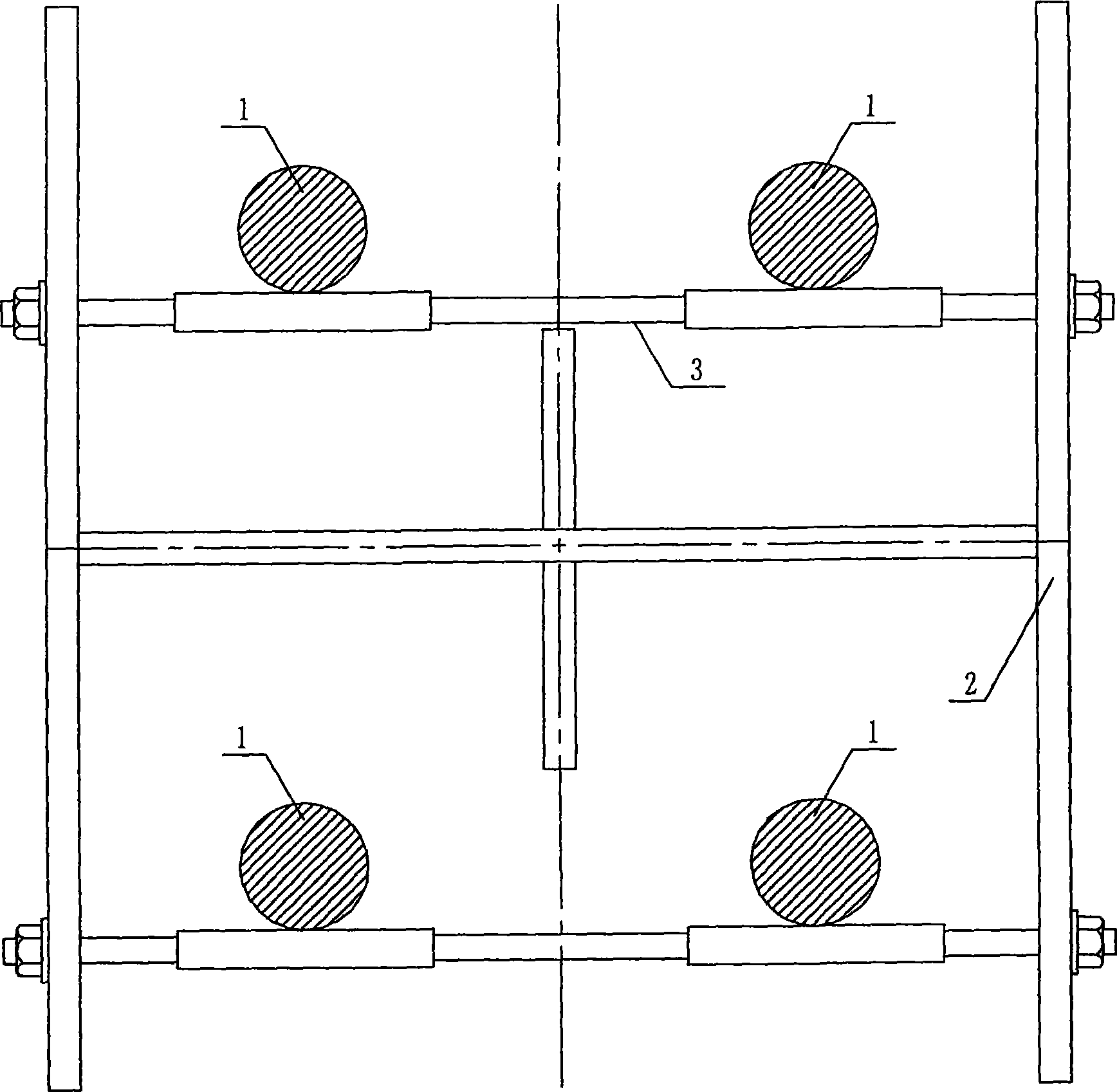

[0008] With reference to the accompanying drawings, the present invention is composed of a steel bar 1 and an auxiliary lanyard 2, the steel bar 1 is provided with a tie rod supporting shaft 3, and the two ends of the auxiliary lanyard 2 are anchored at the nodes at the ends of the steel bar 1 On, the middle rests on the tie rod support shaft 3.

[0009] The present invention is composed of a steel bar 1 and an auxiliary lanyard 2, which absorbs the advantages of a rigid tie bar and a flexible tie bar, and can improve the integrity of the structure. A certain amount of pressure is generated on the rigid tie rod through the auxiliary lanyard, which offsets part of the tensile force of the rigid tie rod to control the size of the component, which is equivalent to the prestressed steel structure tie rod, reducing the tension of the rigid member; it can also effectively reduce the rigid tie rod The internal force of the parts reduces the size of the components, reduces the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com