Composite absorption type heat pump formed by increasing low temperature heat supply terminal

An absorption heat pump, low temperature technology, applied in heat pumps, sorption machines, energy-saving heating/cooling, etc., can solve problems such as insufficient utilization of driving heat and cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

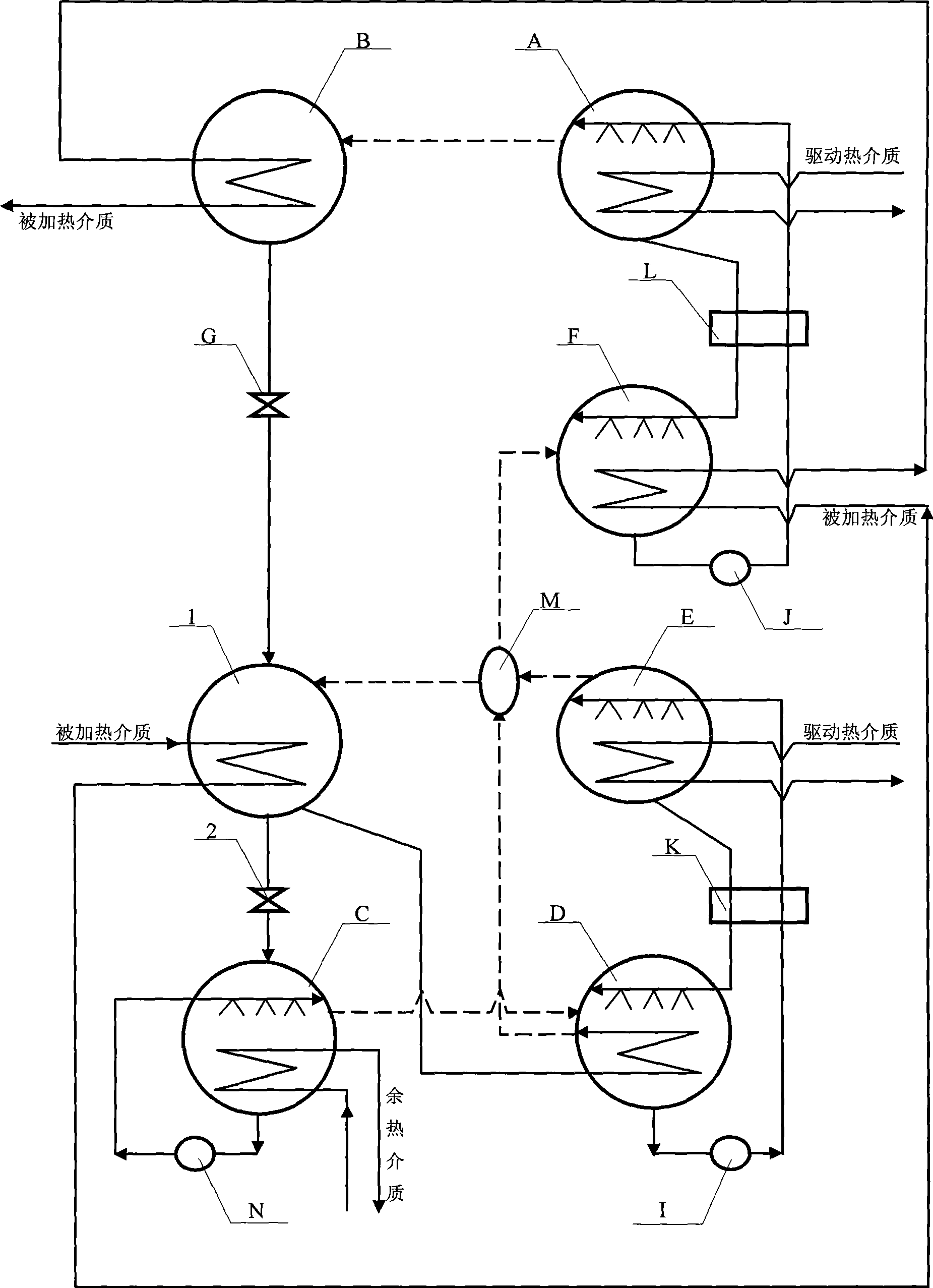

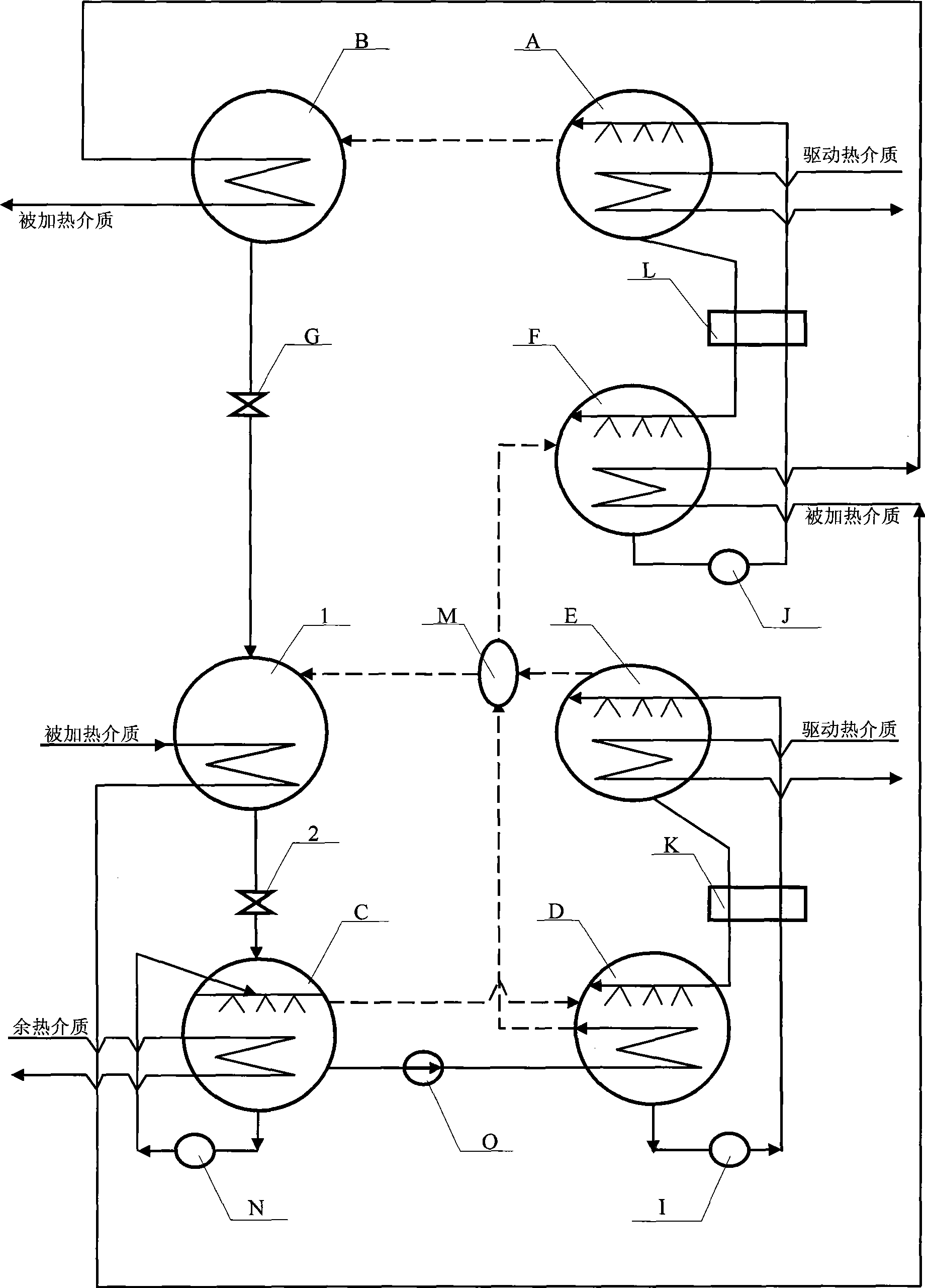

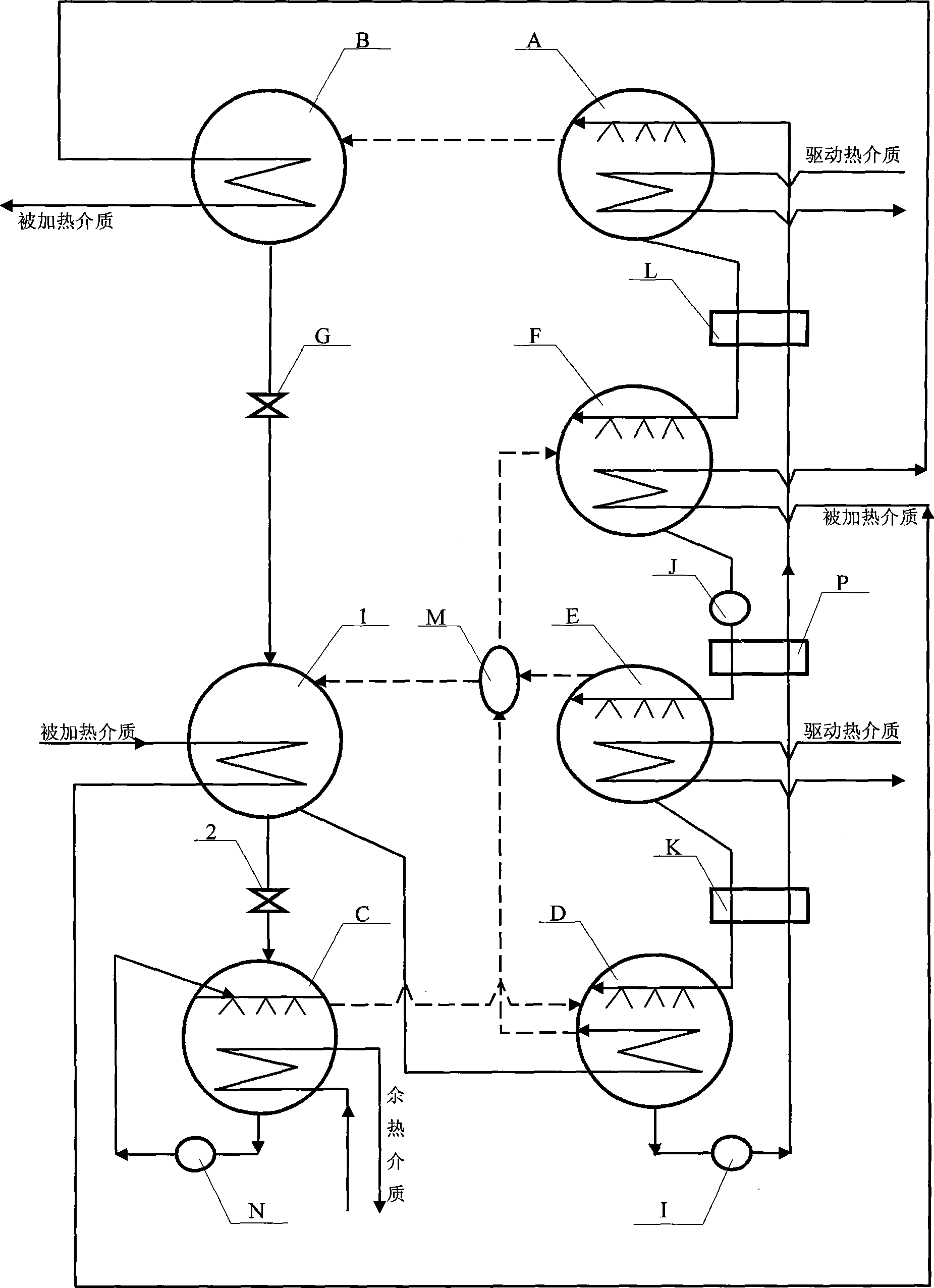

[0030] Take the compound absorption heat pump system provided according to the present invention as an example, such as figure 1 (combined Figure 7 ) shown, the purpose of the present invention is achieved like this:

[0031] ①Structurally, in such as Figure 7 As shown, it consists of secondary generator A, condenser B, evaporator C, absorption-evaporator D, primary generator E, absorber F, first throttle valve G, second throttle valve H, first A solution pump I, a second solution pump J, a first solution heat exchanger K, a second solution heat exchanger L, a steam collection-separator drum M and a refrigerant liquid recirculation pump N, composed of an absorption-evaporator In the two-stage absorption heat pump where D and the first-stage generator E jointly provide refrigerant vapor to the absorber F, a new condenser 1 and a new throttle valve 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com