Waste water advanced purifying process and equipment thereof

A technology for deep purification and waste water, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of heavy burden, inability to oxidize organic molecules, etc., achieve simple structure, reduce burden, COD The effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

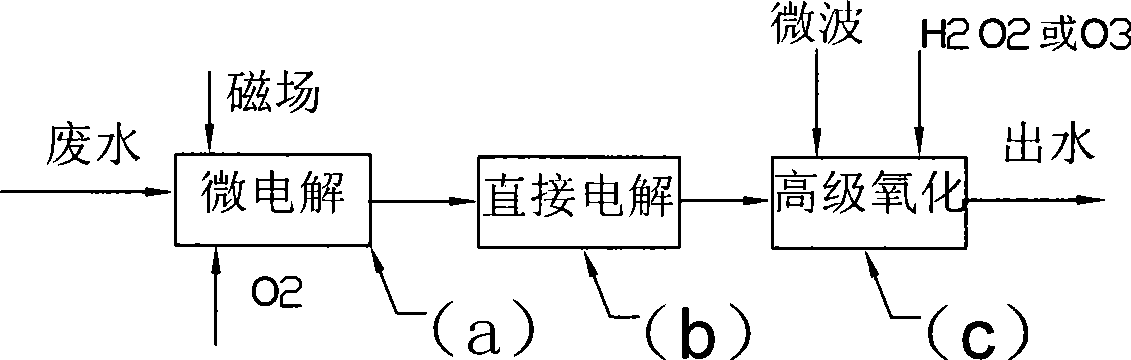

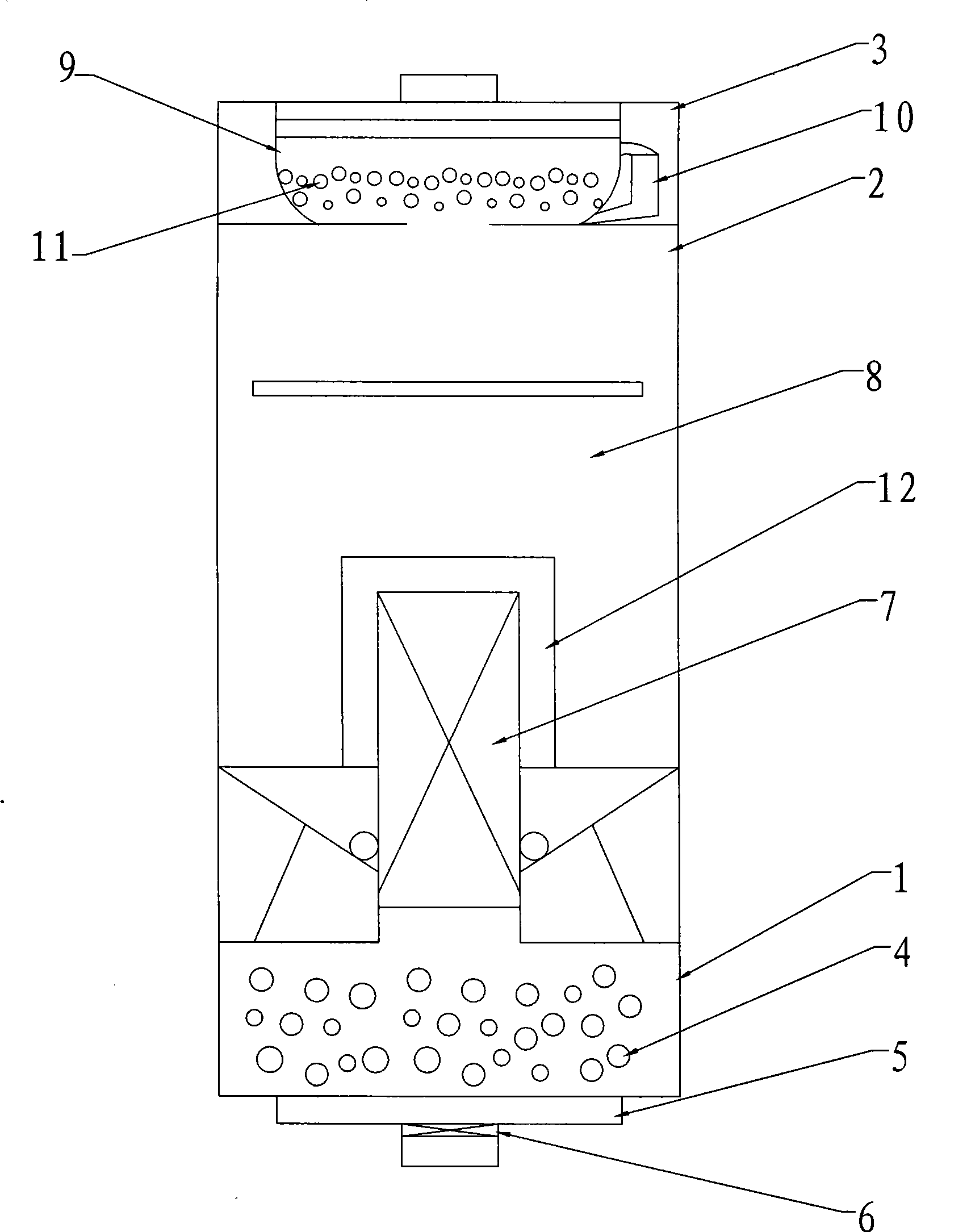

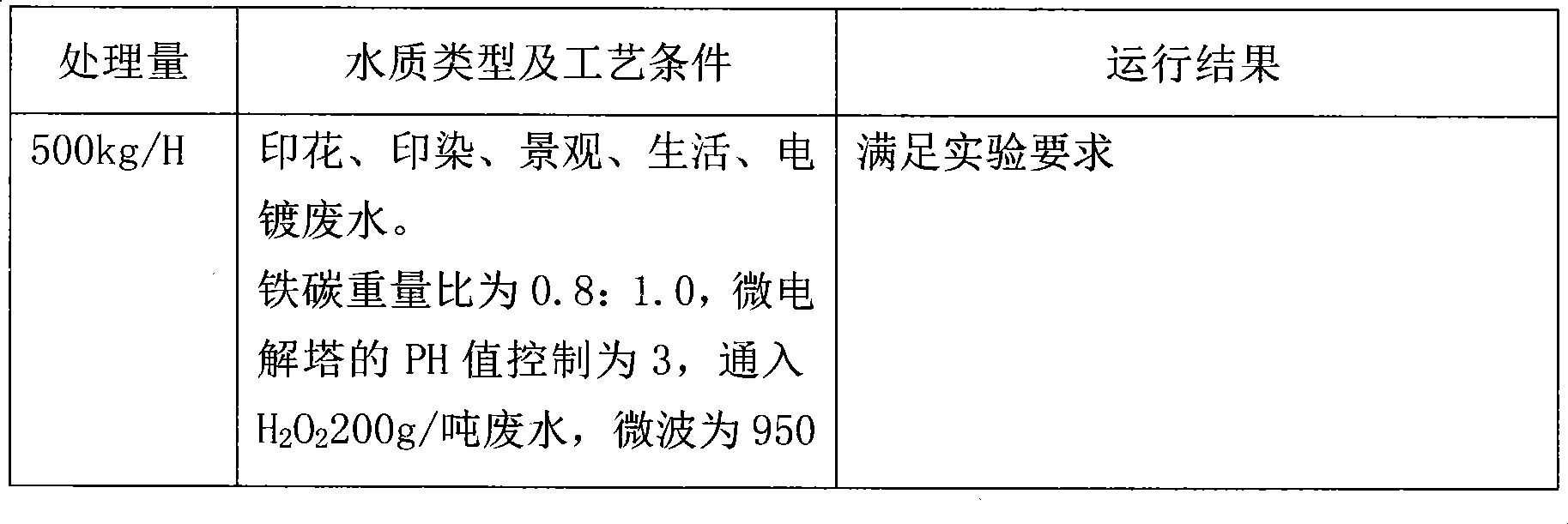

[0017] refer to figure 1 , figure 2 , the waste water flows in from the bottom of the micro-electrolysis tower 1, and flows out from the top. An alloy filler 4 is placed in the micro-electrolysis tower 1. The alloy filler 4 is made up of carbon, iron, copper, aluminum, rare metals, wherein carbon, iron, The weight ratio of copper, aluminum and rare metal is 0.8-1:0.8-1:0.1:0.1:0.05. The alloy filler 4 can also be iron-carbon filler, and the weight ratio of iron-carbon is 0.8-1:0.8-1, preferably 0.8:1. Zero-valent iron and activated carbon form a primary battery in wastewater. Iron is used as the anode to oxidize and emit electrons spontaneously, which can open the ring of organic macromolecules, linearize molecular chains, cut chromophoric groups, and reduce COD. After a long time of use, the iron-carbon filler 4 will agglomerate, which will affect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com