Anti-shock collet

一种轮廓、游丝的技术,应用在钟表、仪器、稳定频率的机构等方向,能够解决损坏的危险增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following description is given for a preferred embodiment in which the collet and balance spring form a single piece made of the same material. New techniques known to those skilled in the art allow almost any profile to be made with a high level of precision and high aspect ratio. If the materials used are metals or alloys, photolithography and electroforming techniques are used. If the materials used are amorphous or crystalline materials such as glass, quartz or silicon, micromachining methods, such as are already used in the manufacture of integrated circuits, for example, are adapted and used.

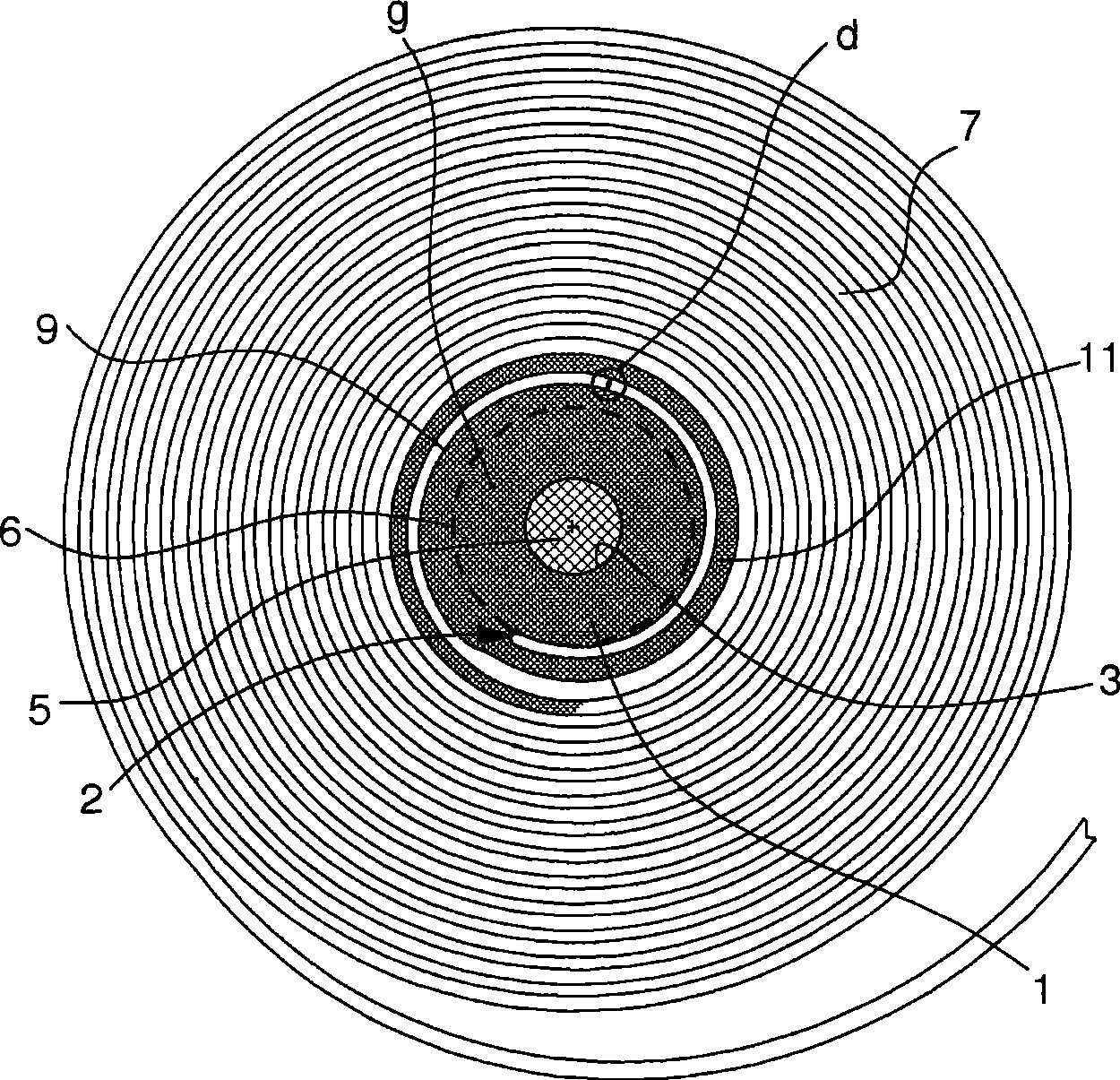

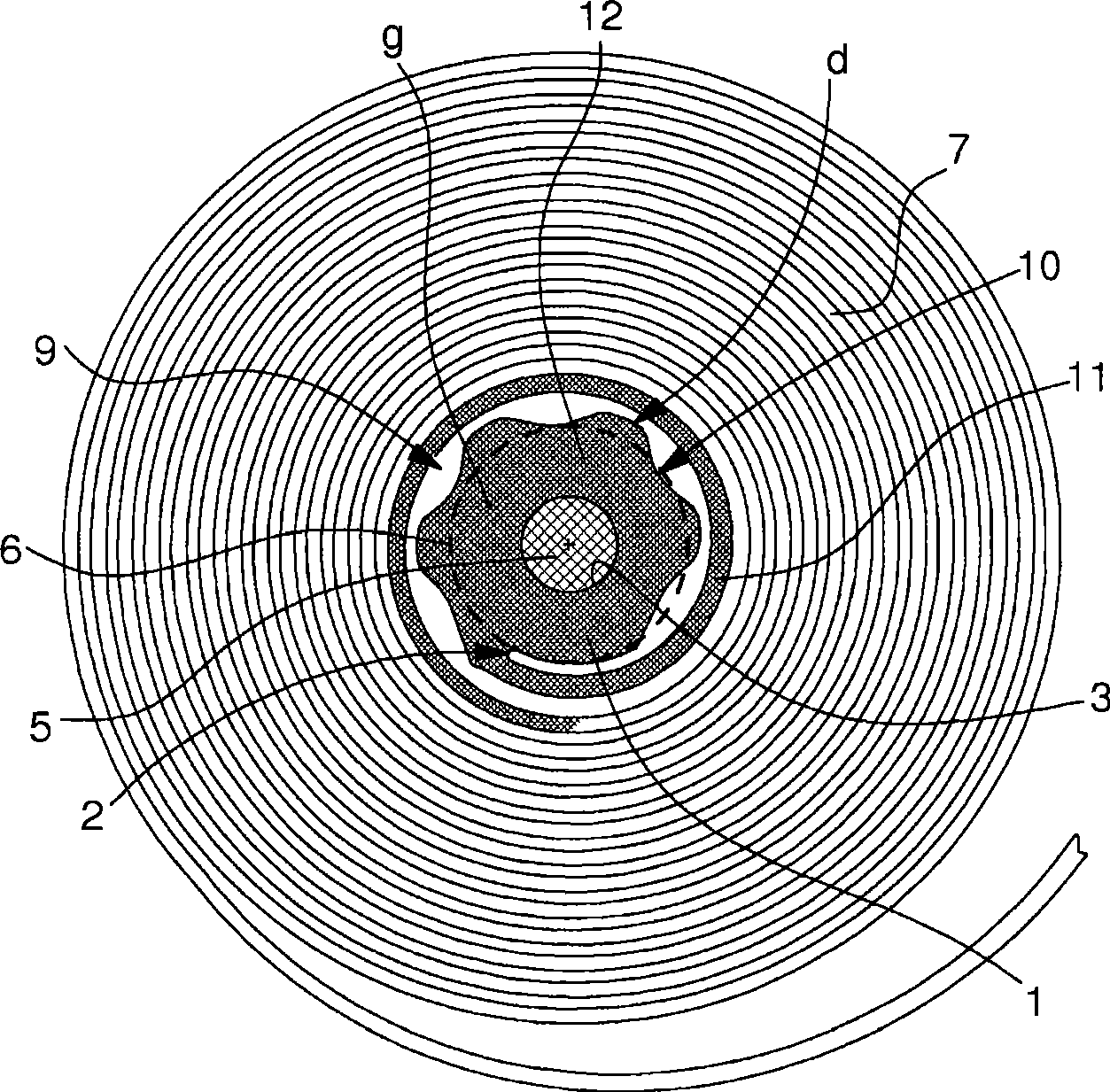

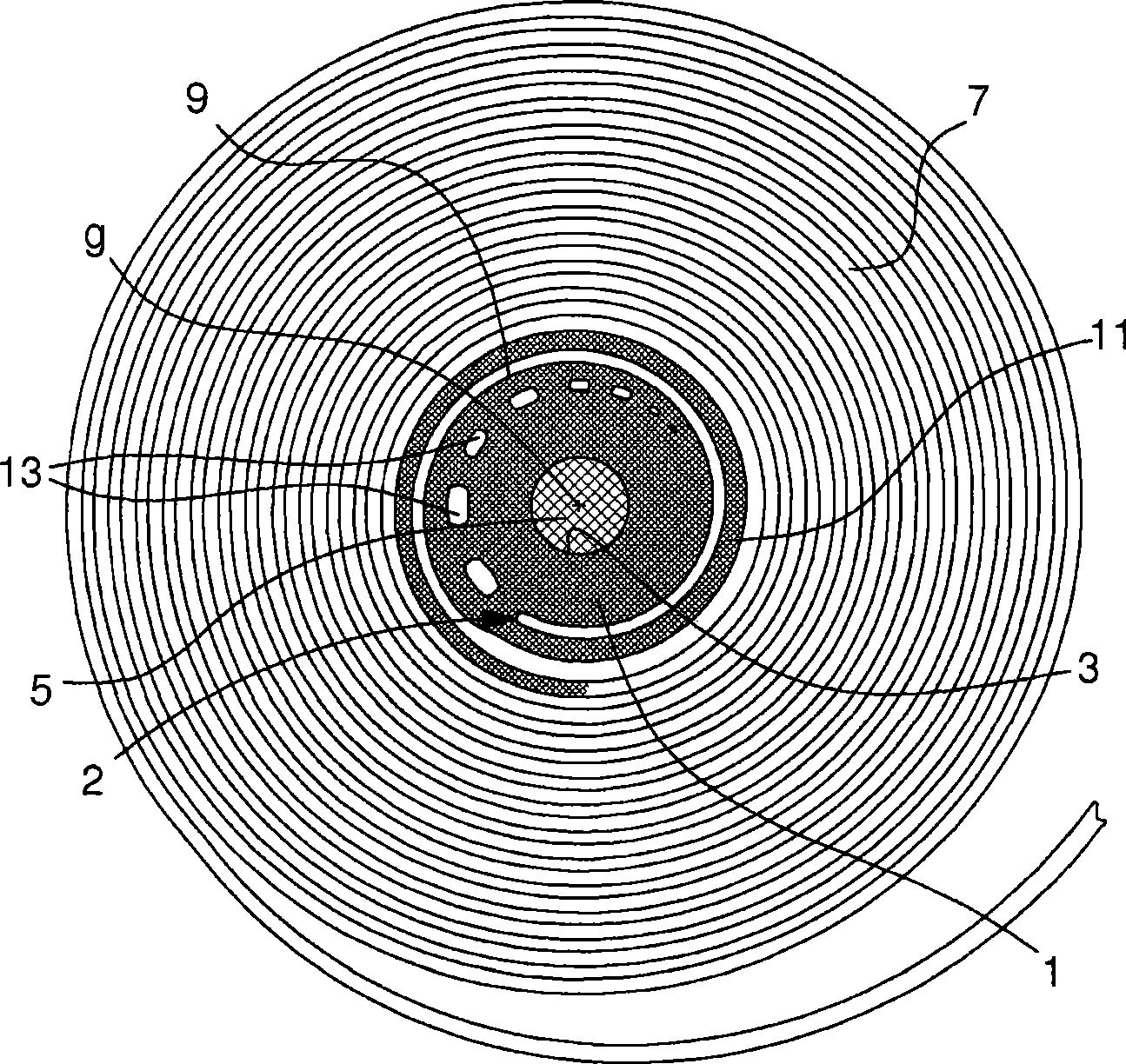

[0015] figure 1 Shows a first embodiment of the collet made in one piece at the same time as the balance spring 7 , that is, without any difference in material at the junction area or joint 2 between the plate 1 of the collet and the first coil 11 of the inner end curve. continuous. Plate 1 includes holes 3 for fastening collets on balance shaft 5 .

[0016] A circl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap