Tunnel air pollutant purification apparatus

A technology of tunnel air and purification device, applied in the field of air purification, can solve the problems such as the inability to meet the requirements of tunnel air pollutant control, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

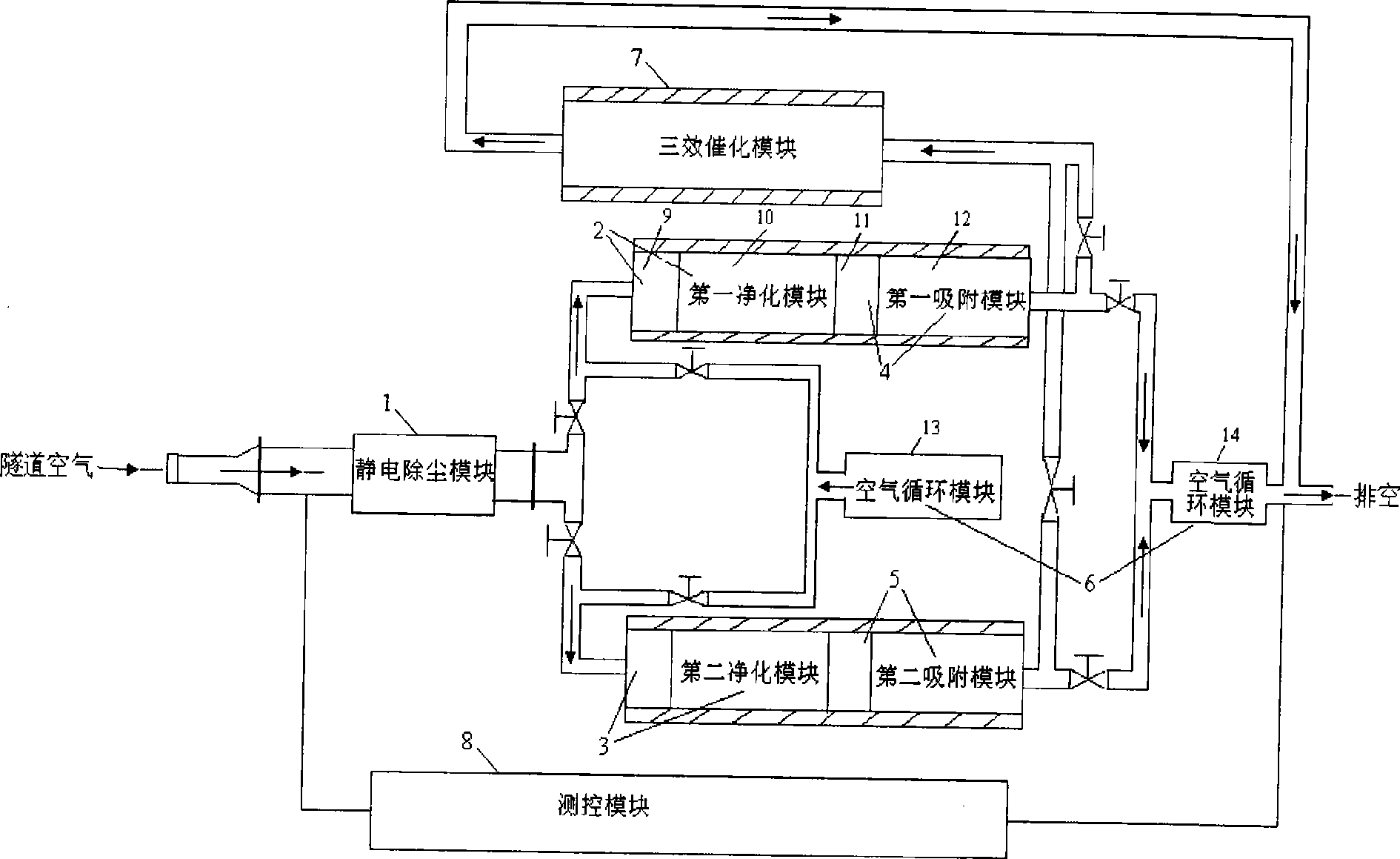

[0029] like figure 1 As shown, this embodiment includes: electrostatic dust removal module 1, first purification module 2, second purification module 3, first adsorption module 4, second adsorption module 5, air circulation module 6, three-way catalytic module 7 and measurement and control module 8, wherein: the input end of the electrostatic precipitator module 1 receives tunnel air, the output end of the electrostatic precipitator module 1 is respectively connected to the input ends of the first purification module 2 and the second purification module 3 and the air inlet of the air circulation module 6, the first The output ends of the purification module 2 and the second purification module 3 are respectively connected to the input ends of the first adsorption module 4 and the second adsorption module 5, and the output ends of the first adsorption module 4 and the second adsorption module 5 are connected to the air circulation module 6 respectively. The exhaust port and the...

Embodiment 2

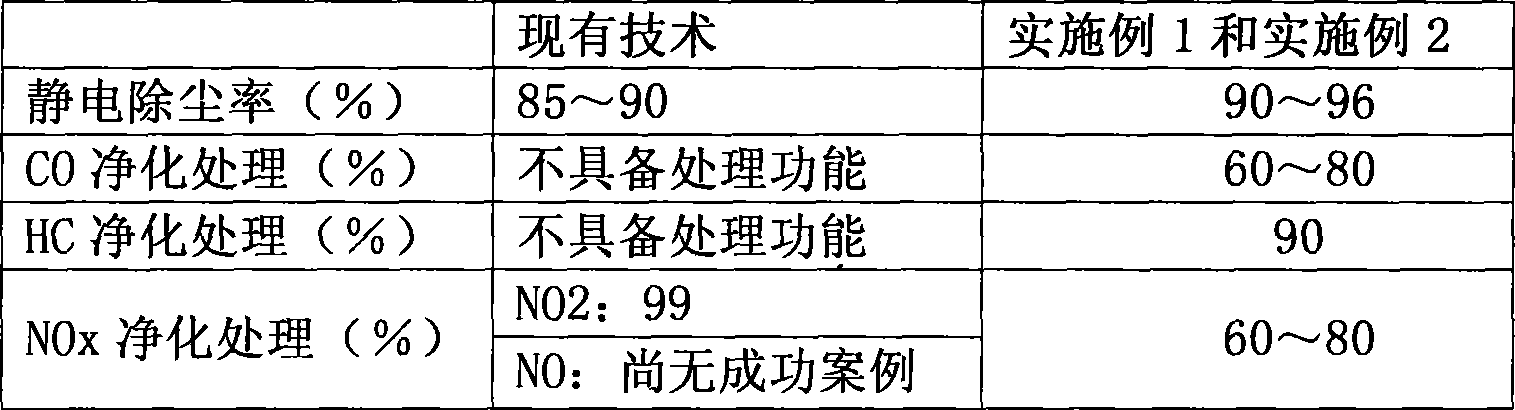

[0046] In Example 2, air purification is carried out in the following manner: the CO purification chamber 10 is filled with 150 to 360 m of modified Ag catalysts that are supported by monolithic honeycomb ceramics. 3 , fill the adsorption chamber 12 with 200-450m of modified monolithic honeycomb activated carbon 3 , the temperature of the two chambers is 5-55°C; the three-way catalytic module 7 is loaded with a modified Pd / Pt three-way catalyst supported by monolithic honeycomb ceramics for 80-120m 3 , the temperature inside the three-way catalytic module is 150-300°C; the processing air volume is 360,000-720,000 m 3 / h; the initial contents of PM, CO, NOx and HC in tunnel air are 5-6 mg / m respectively 3 , 20-40ppm, 5-6ppm and 10-20ppm, the dust removal rate is 90-96%, the CO catalytic oxidation removal rate is 60-75%, and the NOx and HC adsorption removal rates are 60-80% and 90% respectively ; When the adsorption chamber 12 is filled with modified monolithic honeycomb acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com