Rolling washing dryer

A washing-drying machine, drum-type technology, used in household dryers, other washing machines, washing machines with containers, etc., can solve the problems of uneven wetting, loss, and the laundry is not wetted, and reduce wrinkles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

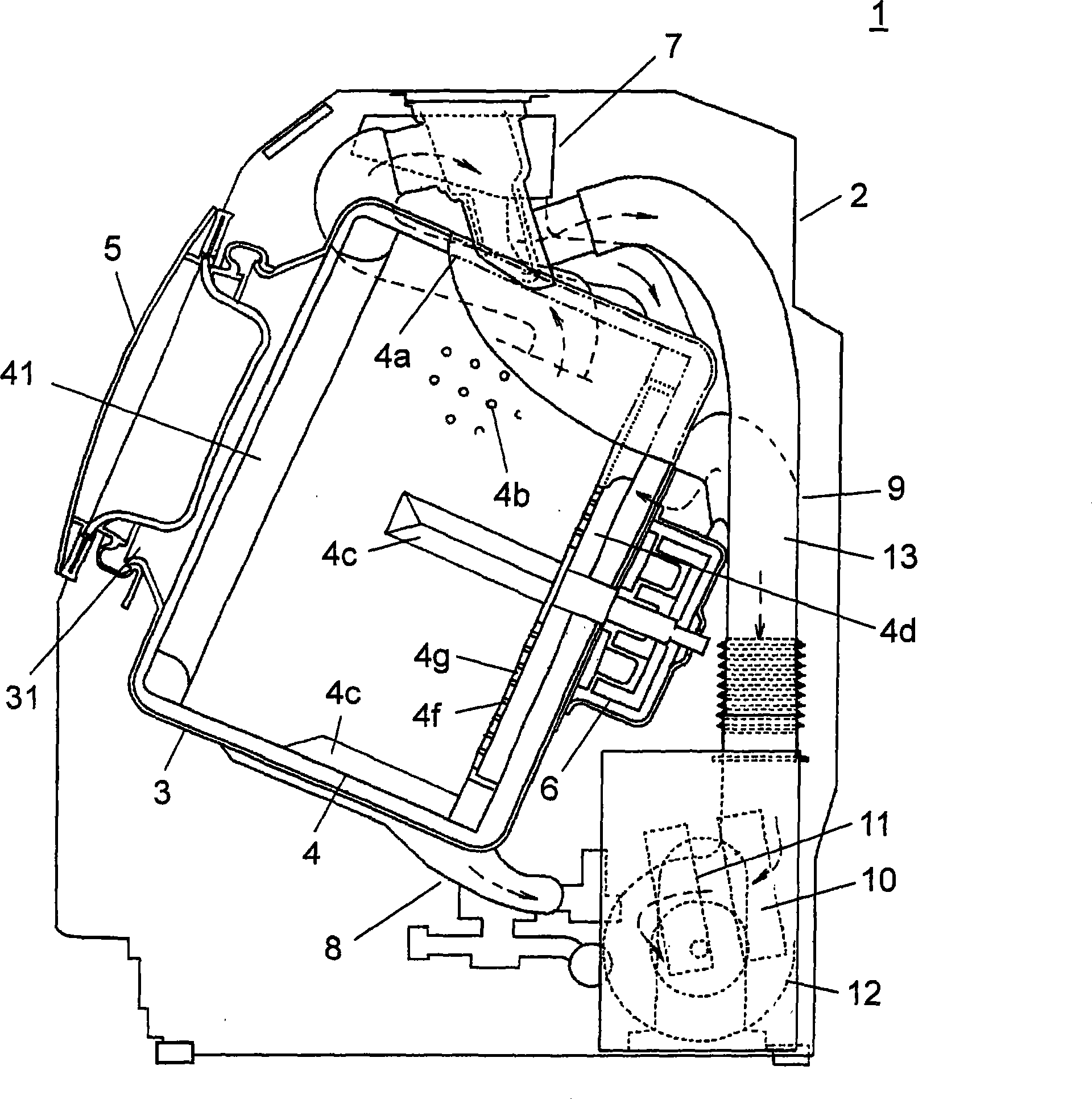

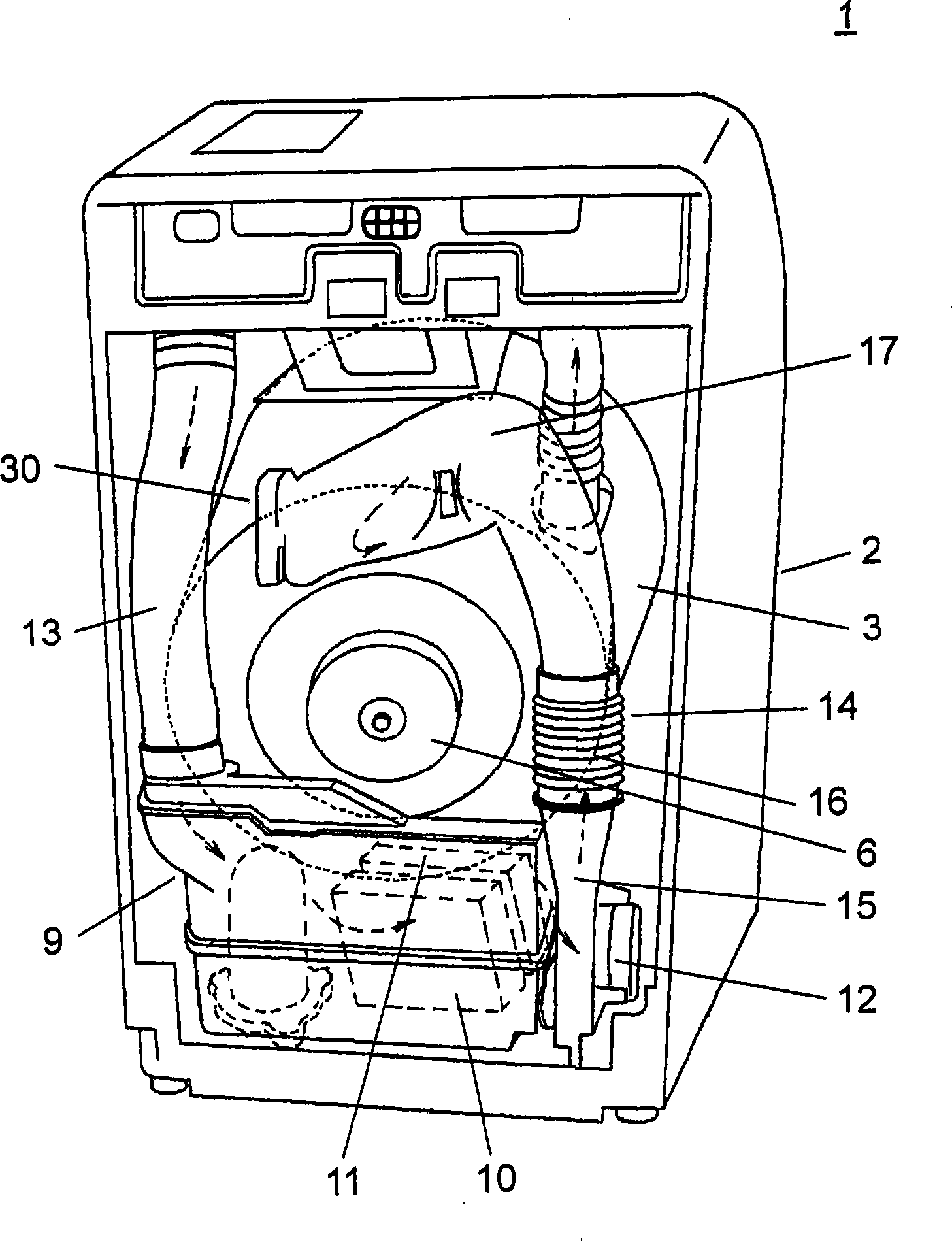

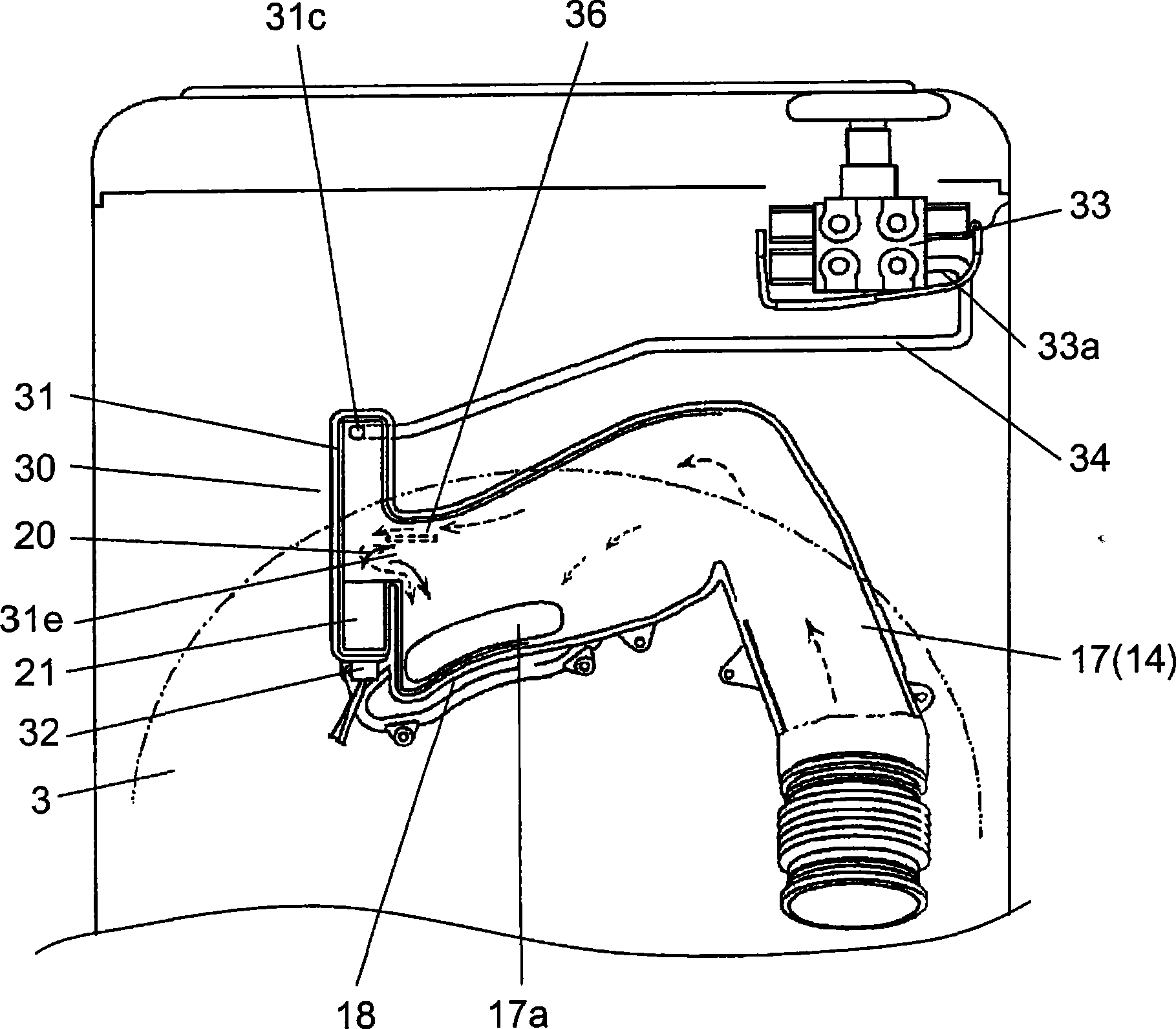

[0075] based on Figure 1 ~ Figure 4 The configuration and operation of the drum-type washer-dryer according to Embodiment 1 of the present invention will be described. figure 1 It is a side sectional view for explaining the structure of the front-loading-type washing-drying machine concerning Embodiment 1 of this invention. figure 2 It is a perspective view seen from the back side of the casing for explaining the arrangement of the air circulation path and the atomizing unit of the drum-type washer-dryer according to Embodiment 1 of the present invention. image 3 It is a partly cut-away configuration diagram for explaining the configuration of the air circulation path and the atomizing unit of the drum-type washer-dryer according to Embodiment 1 of the present invention, viewed from the back side of the housing. Figure 4 It is a side cross-sectional view for explaining the connection structure between the atomization unit and the water tub of the drum type washer-dryer a...

Embodiment approach 2

[0124] Next, refer to Figure 10 , Figure 11A , Figure 11B The bottom wall structure of the drum-type washer-dryer according to Embodiment 2 of the present invention will be described in detail. Figure 10 It is a rear view for explaining the bottom wall structure of the rotary drum of the front-type washer-dryer according to Embodiment 2 of the present invention. Figure 11A , Figure 11B It is a side view sectional view of its different positions. In addition, in Figure 11A , Figure 11BIn the middle, the left side is the inner surface side of the rotating drum. Since the structure of the drum-type washer-dryer according to this embodiment is the same as that of the drum-type washer-dryer in Embodiment 1 except for the bottom wall of the rotary drum, details about the structure of the bottom wall of the rotary drum are omitted. illustrate.

[0125] In Embodiment 1, the radial rib 4h and the circumferential rib 4i which protrudes toward the back side rather than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com