Manufacturing process of high-efficiency and long-life membrane electrodes for proton exchange membrane fuel cells

A proton exchange membrane and fuel cell technology, applied in fuel cells, battery electrodes, sustainable manufacturing/processing, etc., can solve problems such as reducing the service life of membrane electrodes, affecting proton conduction efficiency, and increasing the resistance of proton exchange membranes and catalytic layers , to achieve the effect of improving power generation efficiency, improving proton conduction efficiency, and ensuring water locking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

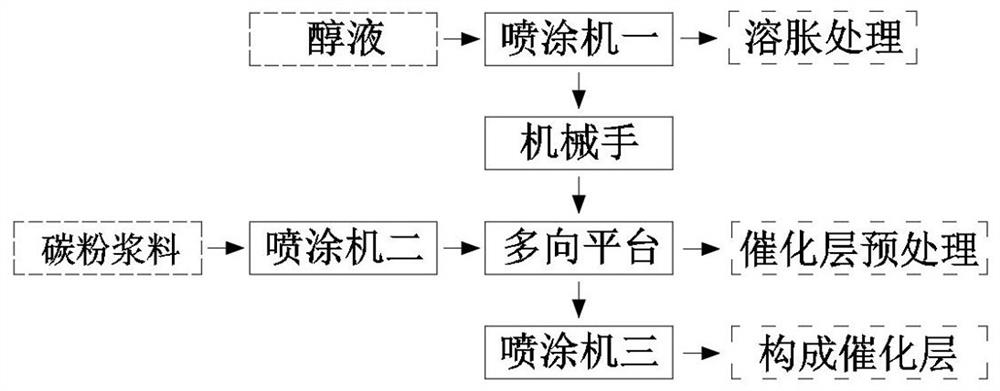

[0026] see figure 1 , a kind of embodiment one that the present invention provides: the high-efficiency long-life membrane electrode manufacturing process for proton exchange membrane fuel cell, comprising the following process steps:

[0027] S1. Preparation of carbon powder slurry: prepare according to the ratio of 3:1:2, take three parts of carbon powder, one part of conductive mica powder and one part of perfluorosulfonic acid resin and fully mix them for later use. The toner powder has good conductivity and conduction effect , Conductive mica powder is resistant to high temperature and has high strength. It can be mixed in the carbon powder slurry to improve the strength of the membrane electrode;

[0028] S2. Preparation of catalyst slurry: Prepare according to the ratio of 3:1:1, take three parts of carbon powder, one part of platinum black and one part of perfluorosulfonic acid resin and fully mix them for later use. Platinum black has high activity and good catalytic ...

Embodiment 2

[0035] Embodiment 2: On the basis of Embodiment 1, the difference is: during Y-axis spraying, the spraying machine moves horizontally and uniformly along the Y-axis direction, and the initial distance between the nozzle of the spraying machine and the proton exchange membrane is controlled at 8-12 cm. The multi-directional platform rises at a constant speed with the movement of the sprayer, and the distance between the nozzle of the sprayer and the proton exchange membrane is always controlled at 8-12 cm. The pressure of the sprayer is changed to compensate for the change in distance, and the pressure adjustment accuracy is required to be extremely high. It is simpler to use the height of the multi-directional platform to compensate for the distance between the nozzle of the sprayer and the proton exchange membrane, and the precision is easier to control.

Embodiment 3

[0036] Embodiment 3: On the basis of Embodiment 1, the difference is that when spraying on the Y-axis and X-axis, the multi-directional platform is turned 30-40 degrees along the X direction, and then turned 30-40 degrees along the Y-axis direction. The diversity of mesopores after the surface of the proton exchange membrane is swelled can be sealed through the two-stage direction adjustment of the X-axis and the Y-axis. The spraying machine moves horizontally and uniformly along the Y-axis direction. The initial spacing is controlled at 8-12 cm, the spraying pressure is constant, the multi-directional platform rises at a constant speed with the movement of the sprayer, and the distance between the nozzle of the sprayer and the proton exchange membrane is always controlled at 8-12 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com