Magnetic suspension drum-type washing machine

A drum washing machine and magnetic levitation technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of reducing product reliability, reducing product washing volume, and reducing stability, so as to increase stability, increase stability and Reliability, the effect of reducing the transmission of swing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

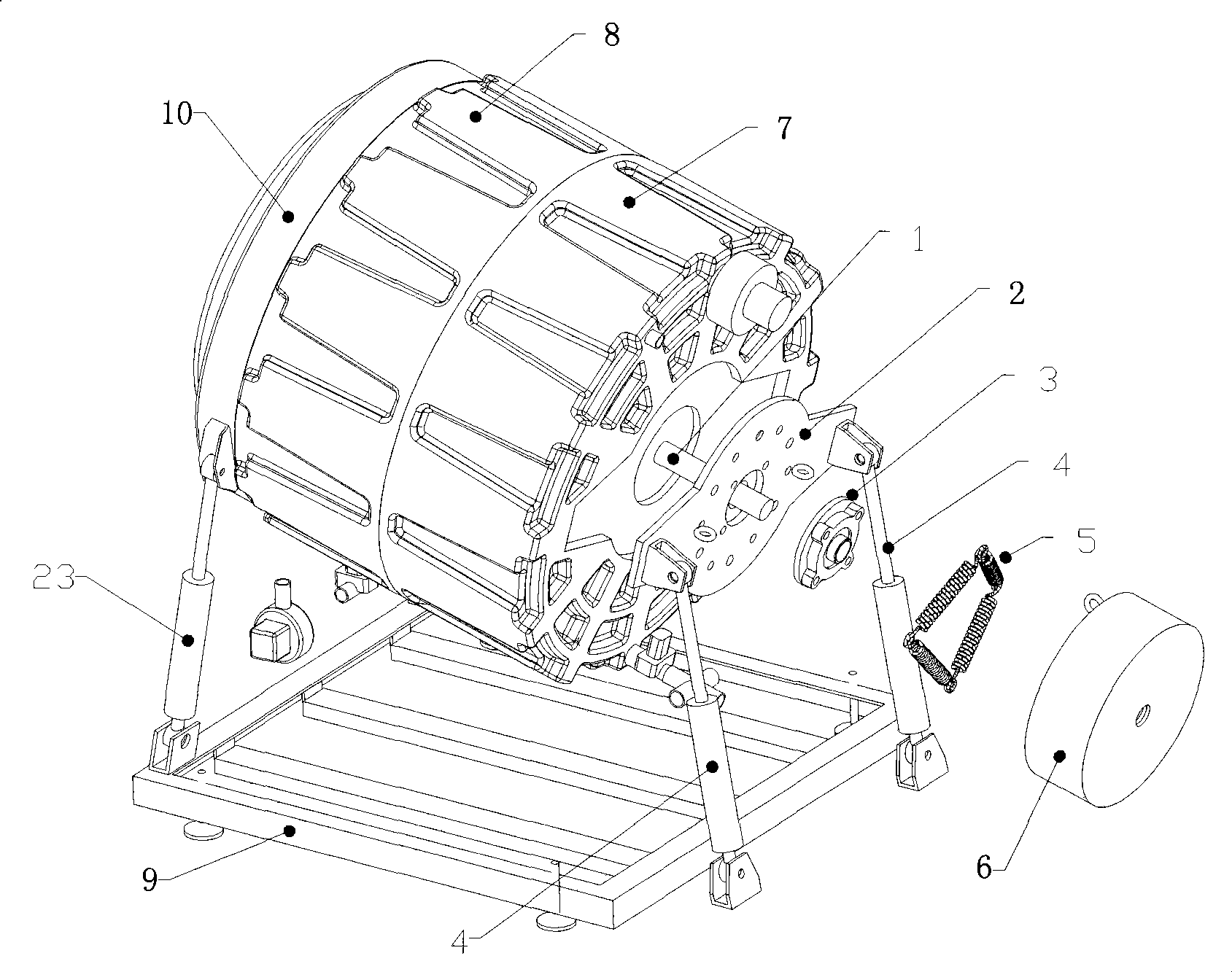

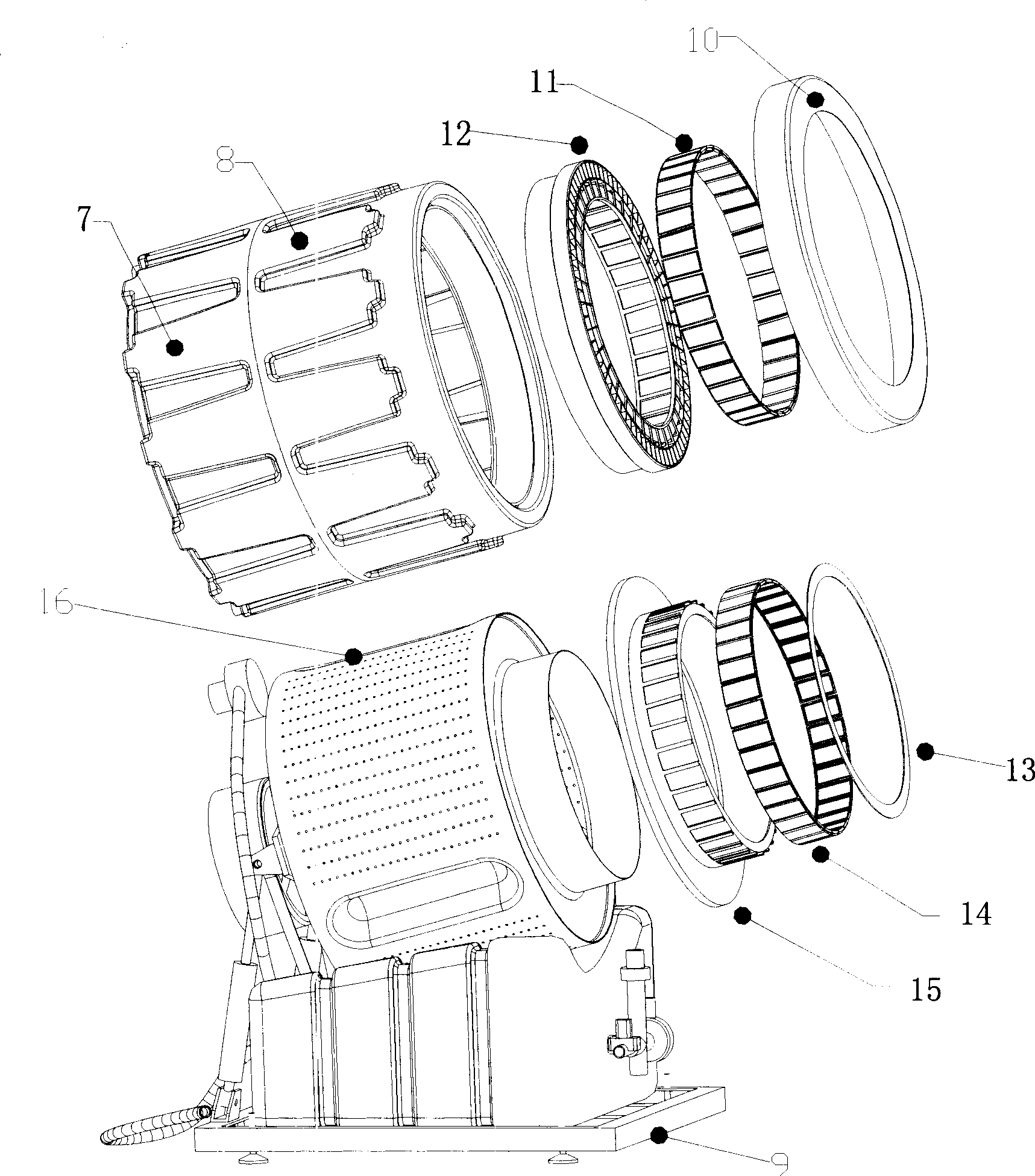

[0019] exist figure 1 Among them, the rotating shaft (1) is connected with the drum (16) to form a whole, the spherical bearing with seat (3) is installed on the rotating shaft (1), and fixed on the bearing bracket (2), and the bearing bracket (2) is fixed on the outer cylinder- 1(7), the upper end of the shock absorber-1(4) is fixed on the bearing bracket (2), and the lower end is fixed on the base (9);

[0020] exist figure 1 , figure 2 , among Fig. 5, the rotor of driving motor (6) is connected with rotating shaft (1), and drives rotating shaft (1), and four limit springs (5) are connected to form a prism, and the A.C two angles of prismatic and driving The stator part of the motor (6) is connected, and the two corners of the prismatic B.D. are fixed on the bearing bracket (2), and the rotation of the stator part of the drive motor is limited by the spring, and the motor can also swing with the swing of the rotating shaft;

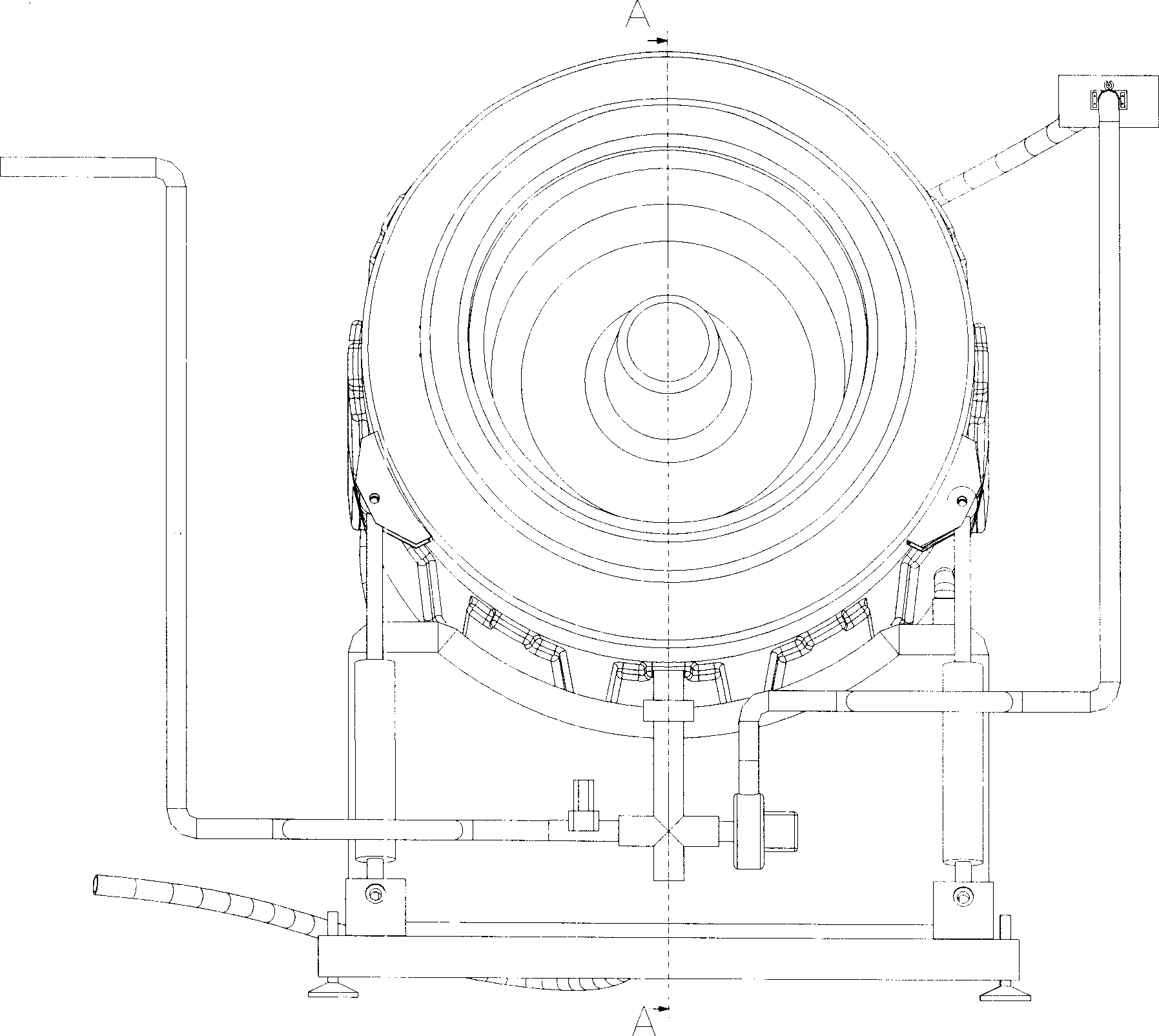

[0021] exist image 3 ,Figure 5, Figure 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com