Method for detecting exhaust spark trap device for automobile and detecting test stand

A spark extinguisher and detection method technology, which is applied in the testing of machines/structural components, engine testing, instruments, etc., can solve the problems that affect the accuracy of data processing, the difficulty of guaranteeing the detection accuracy, and the difficulty of adjustment, etc., and achieve the detection data The effect of accurate processing, convenient detection operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

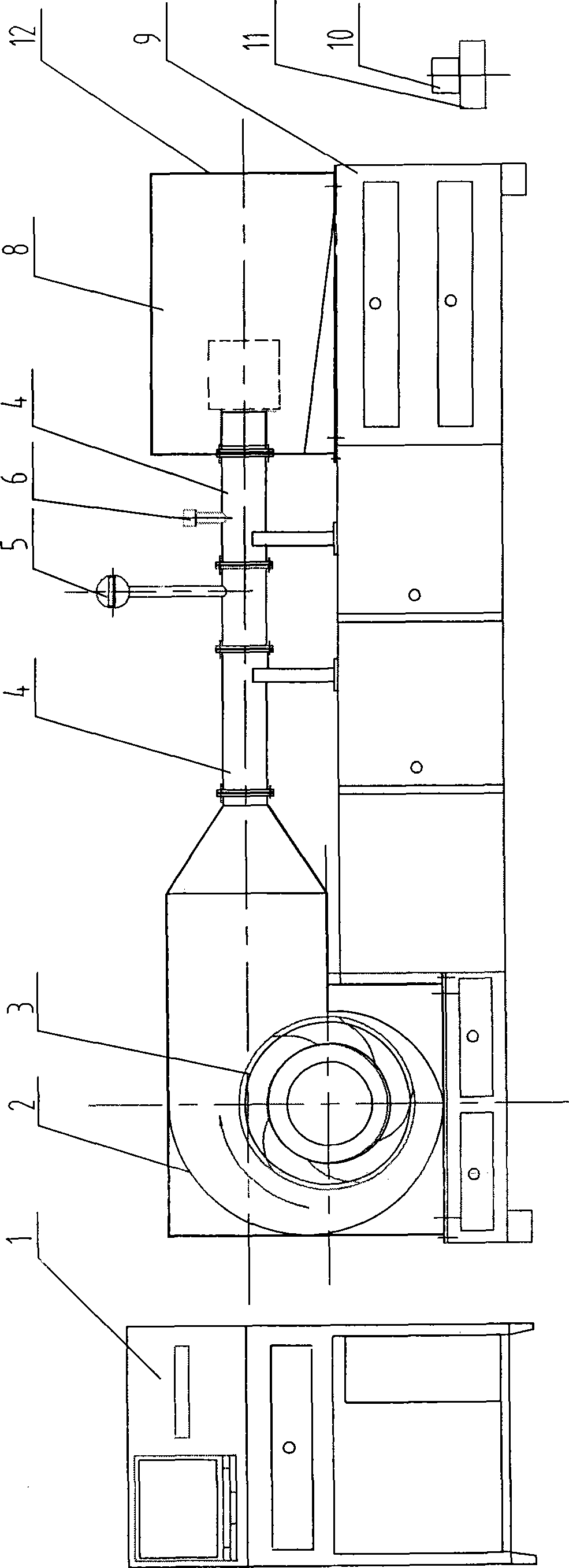

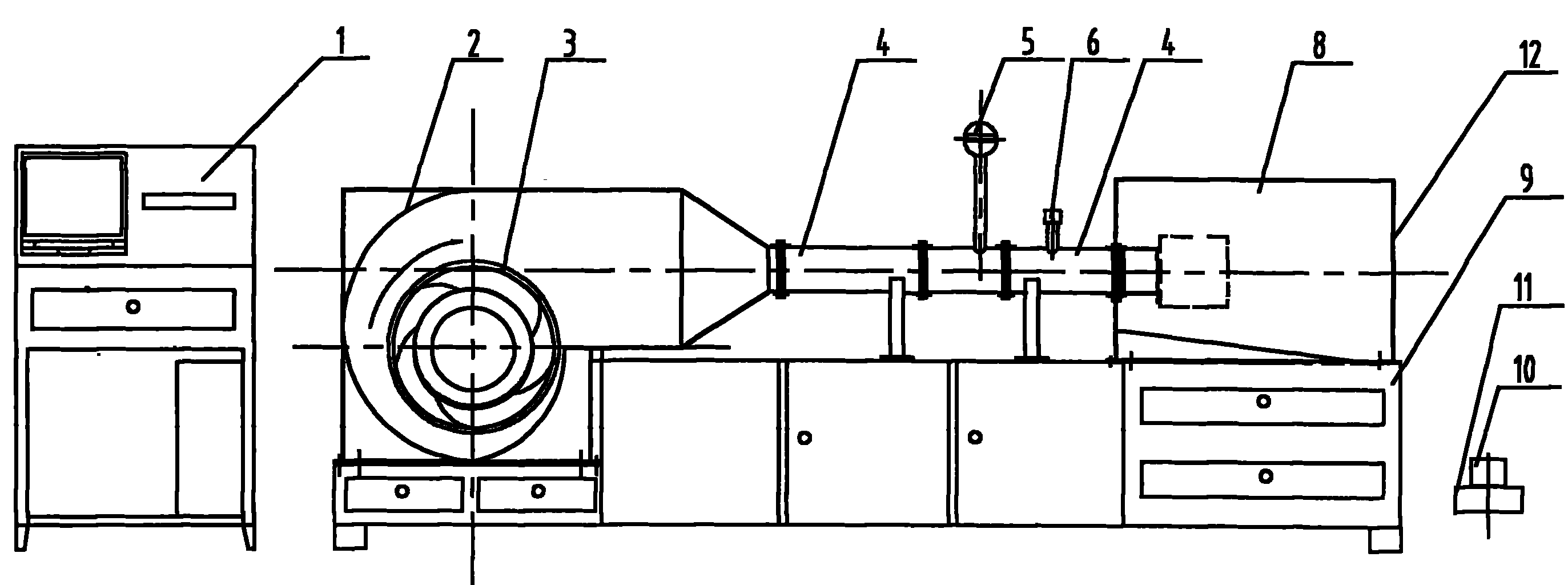

[0021] Description will be made in conjunction with the accompanying drawings. Fan 3 in the figure is an intelligent centrifugal fan of model R3G500-AG06-03, conveying pipe 4, and activated carbon particle collection device 8 are installed on the workbench 9, and the left side is the detection test bench control system 1, and the detection test bench control system 1 is equipped with The software RS232 / RS484 (21487-1-0174) that controls the speed program of the fan 3, the diameter of the exhaust tailpipe of the motor vehicle engine is graded according to the diameter of the commonly used motor vehicle exhaust tailpipe, from 30mm to 120mm in diameter, with a value of 5mm There is one level, diameter ≥ 30mm to <35mm, diameter ≥ 35mm to <40mm, ... diameter ≥ 120mm to <120mm is one level, a total of 18 levels, of course, under the premise of ensuring the detection accuracy requirements, other methods can be used The classification method, the more the classification, the finer the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com