Formulation management and technique control system of closed-smelting machine

A formula management and process control technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, novel control system of the present invention is described in further detail:

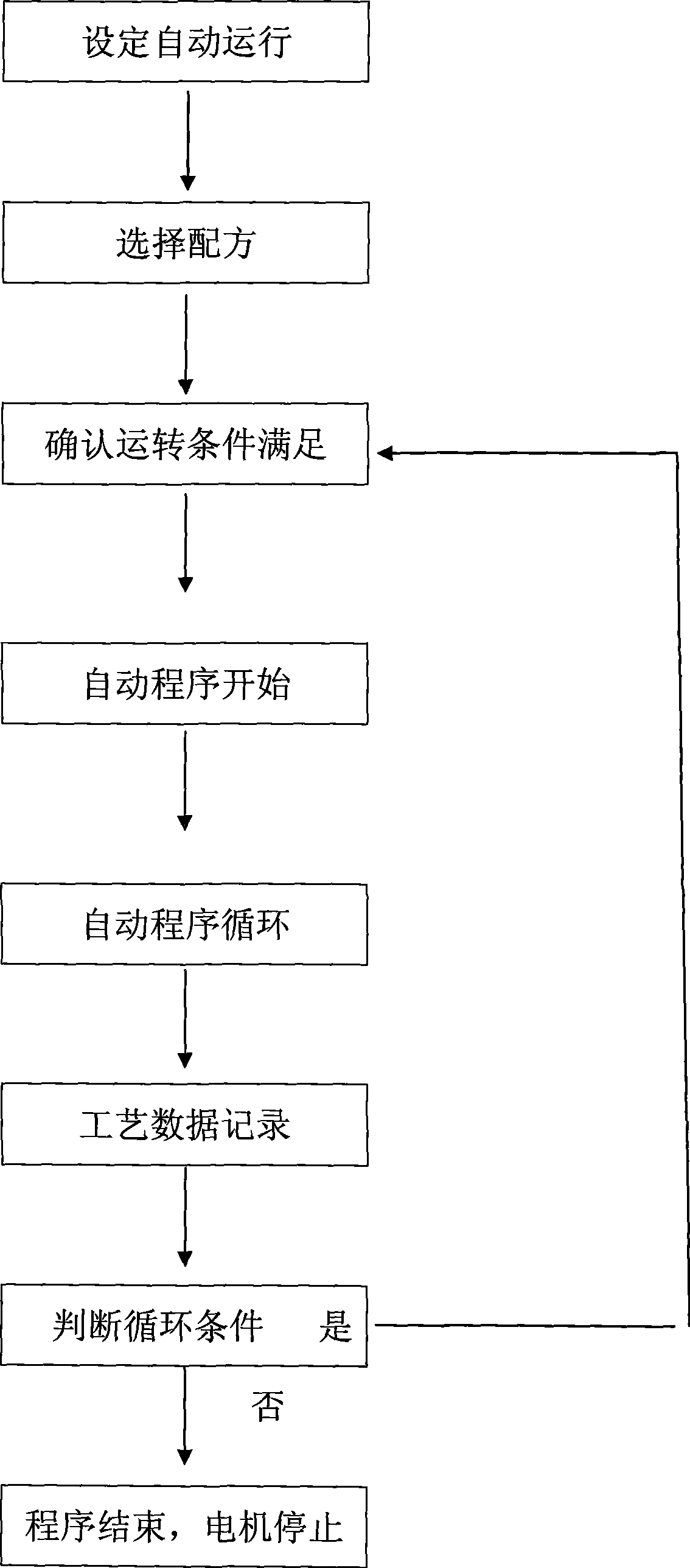

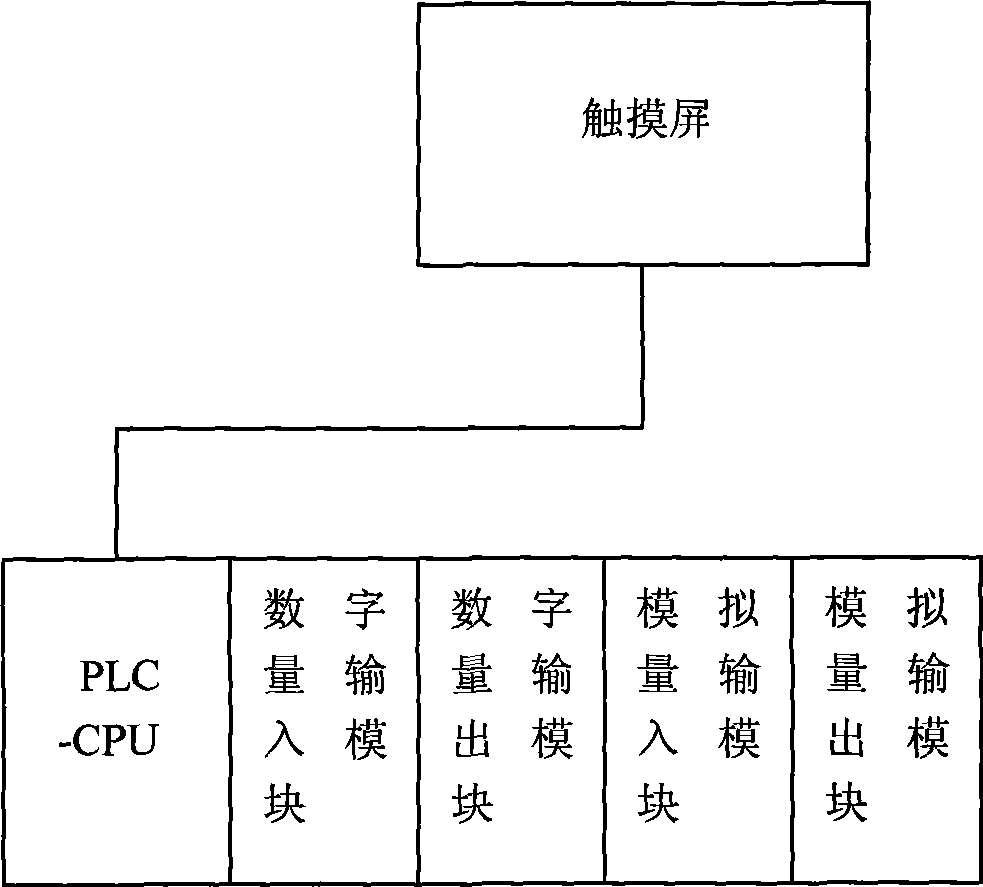

[0011] Such as figure 2 In the internal mixer formula management and process control system shown, the touch screen is connected to the storage and control module of the PLC. The formula data and process data are stored in the PLC, and are displayed by the display module through the touch screen. The control system is as follows: figure 1 As shown, under the condition that the internal mixer of the equipment meets the production conditions, first enter the automatic operation unit through the touch screen, where 200 formulas are stored, select the production formula from the formula data by operating the touch screen, and start the automatic operation after the relevant operating conditions are met. The equipment executes according to the parameters set in the formula and in accordance with the process sequence, and stores the corresponding pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com