Comprehensive recovery and utilization method of various waste waters in iron and steel plant

A technology for iron and steel plants and wastewater, applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

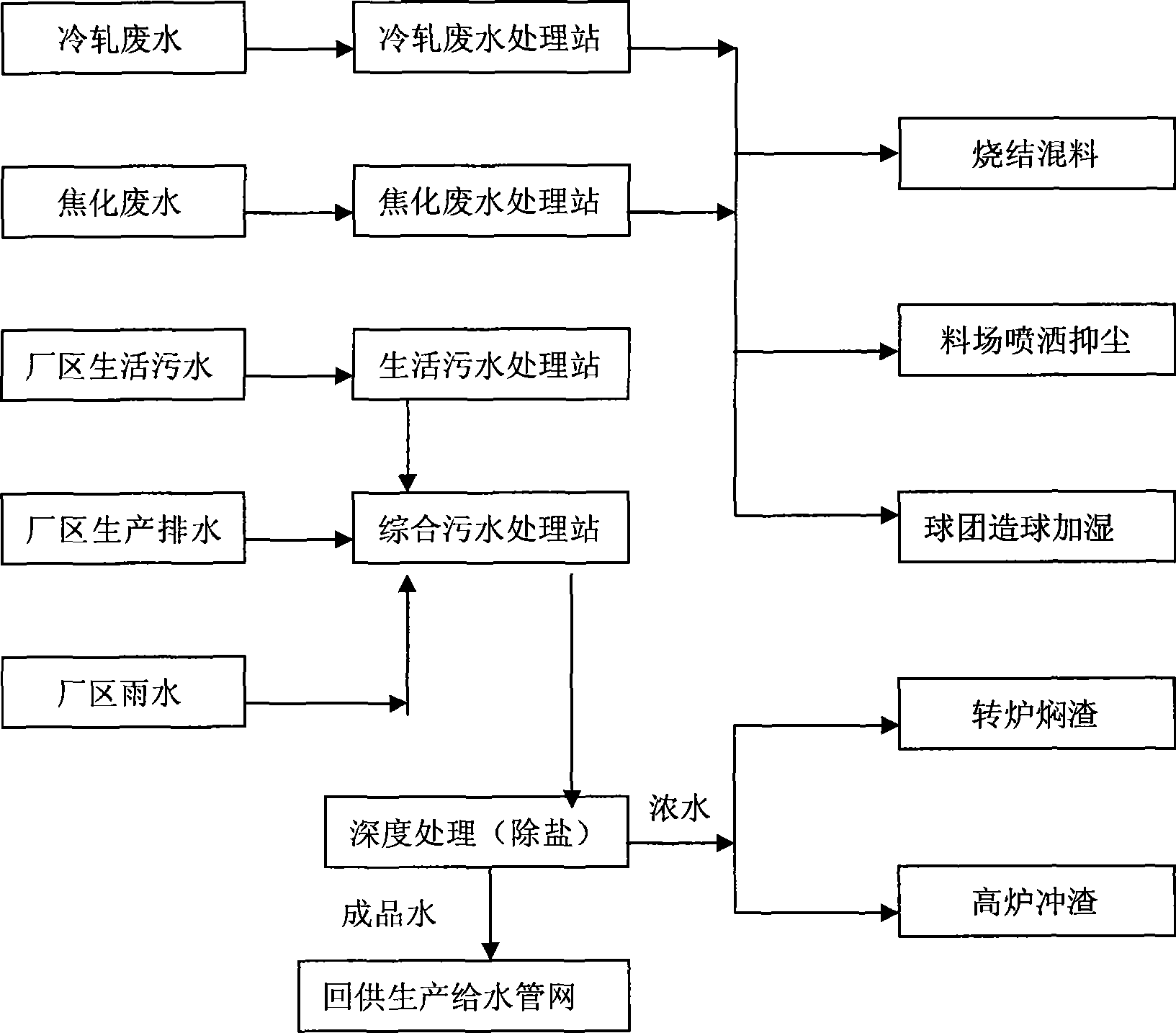

Method used

Image

Examples

Embodiment Construction

[0015] In order to overcome the difficulties encountered in the reuse of various waste water in iron and steel plants and to seek better comprehensive waste water recycling technology, the purpose of this invention is to design a variety of waste water in iron and steel plants with smooth flow, easy production and reasonable economy. Comprehensive recycling technology.

[0016] The specific implementation method is: according to the location of each process in the iron and steel plant, the area is divided, and the water quality and water volume balance calculation is carried out in combination with the drainage characteristics and water consumption characteristics of different processes. According to the calculation results, the layout of the water supply and return pipe network is optimized, and the separation system of production sewage, industrial wastewater, domestic sewage, and rainwater drainage in the factory area is adopted. Design reasonable wastewater treatment facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com