Hydraulic valve assembly with direction sliding valve and regeneration flow dividing valve with pressure compensation

A diverter valve, slide valve technology, applied in the field of hydraulic system, can solve problems such as affecting the efficiency of regeneration mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

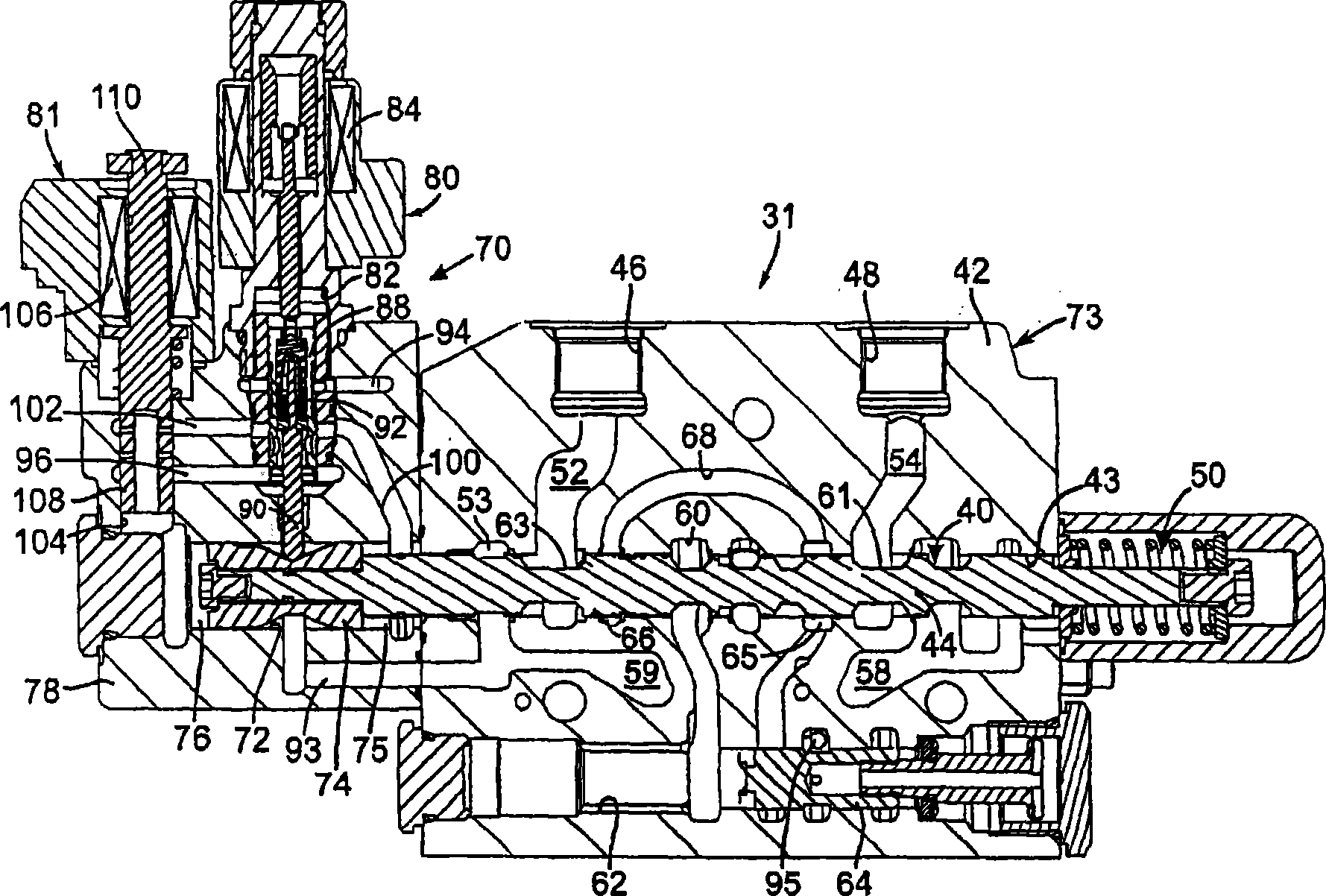

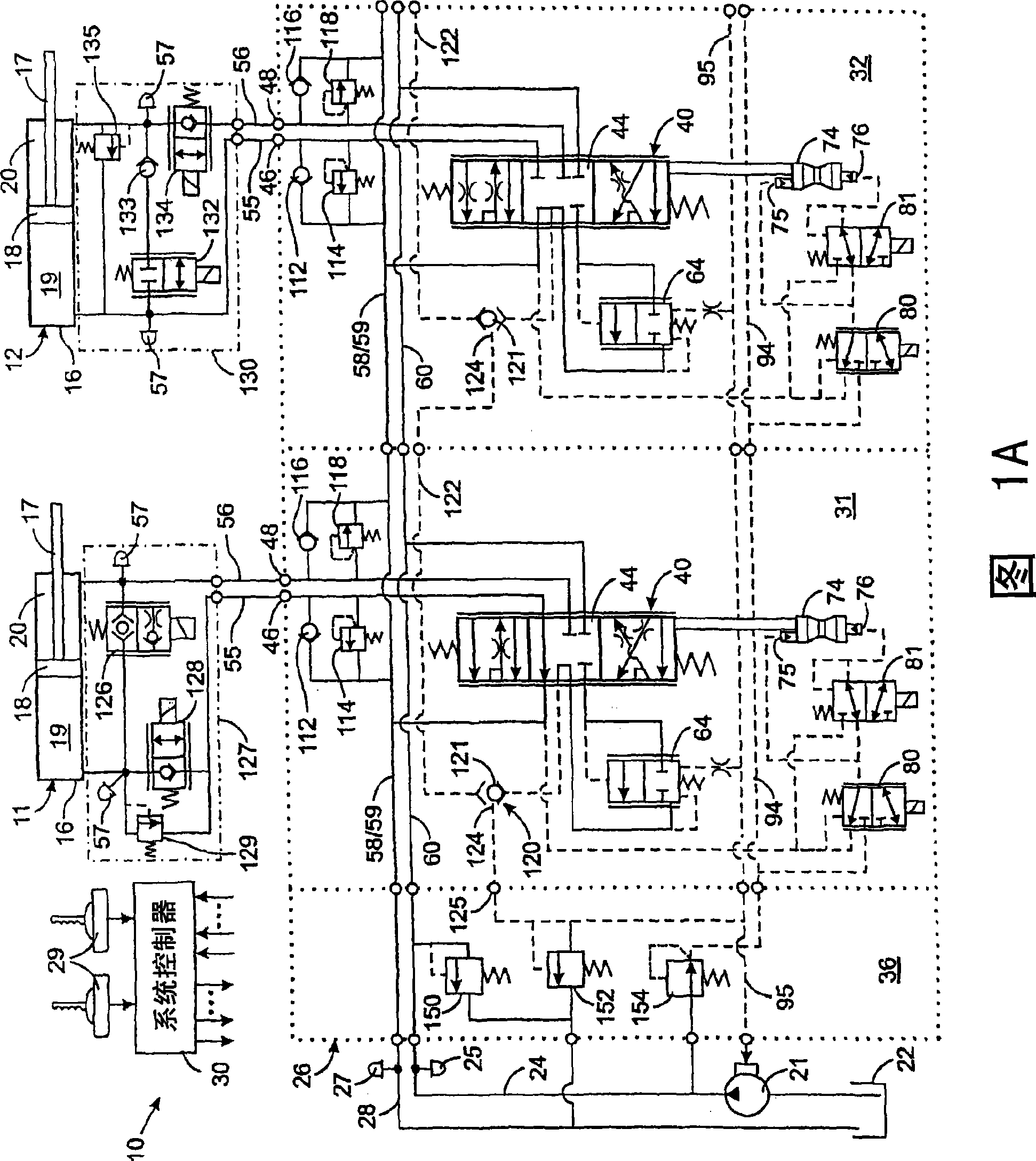

[0016] first reference figure 1 A and 1B, the hydraulic system 10 on the machine controls five hydraulic actuators 11 , 12, 13, 14 and 15 such as cylinder / piston assemblies. Each hydraulic actuator 11-15 comprises a hydraulic cylinder 16 with a movable piston 18 to which a piston rod 17 is connected. The piston 18 delimits a hydraulic head chamber 19 and a piston rod chamber 20 within the hydraulic cylinder, wherein first and second ports respectively hydraulically connected to these chambers are provided. It should be understood that other types of hydraulic actuators, such as rotary motors, may be used with the present invention.

[0017] The hydraulic system 10 also includes a variable displacement pump 21 that draws fluid from a tank 22 and provides fluid under pressure to a supply line 24 . The supply conduit is connected to a control valve assembly 26 which controls the flow of fluid to and from the hydraulic actuators 11-15. Fluid returning from the hydraulic actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com