Multiple-pass joint

A technology for multi-pass joints and connectors, applied in the field of multi-pass joints, can solve the problems of increased material consumption, cumbersome and inconvenient operation, etc., and achieve the effect of saving materials and simple and convenient operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

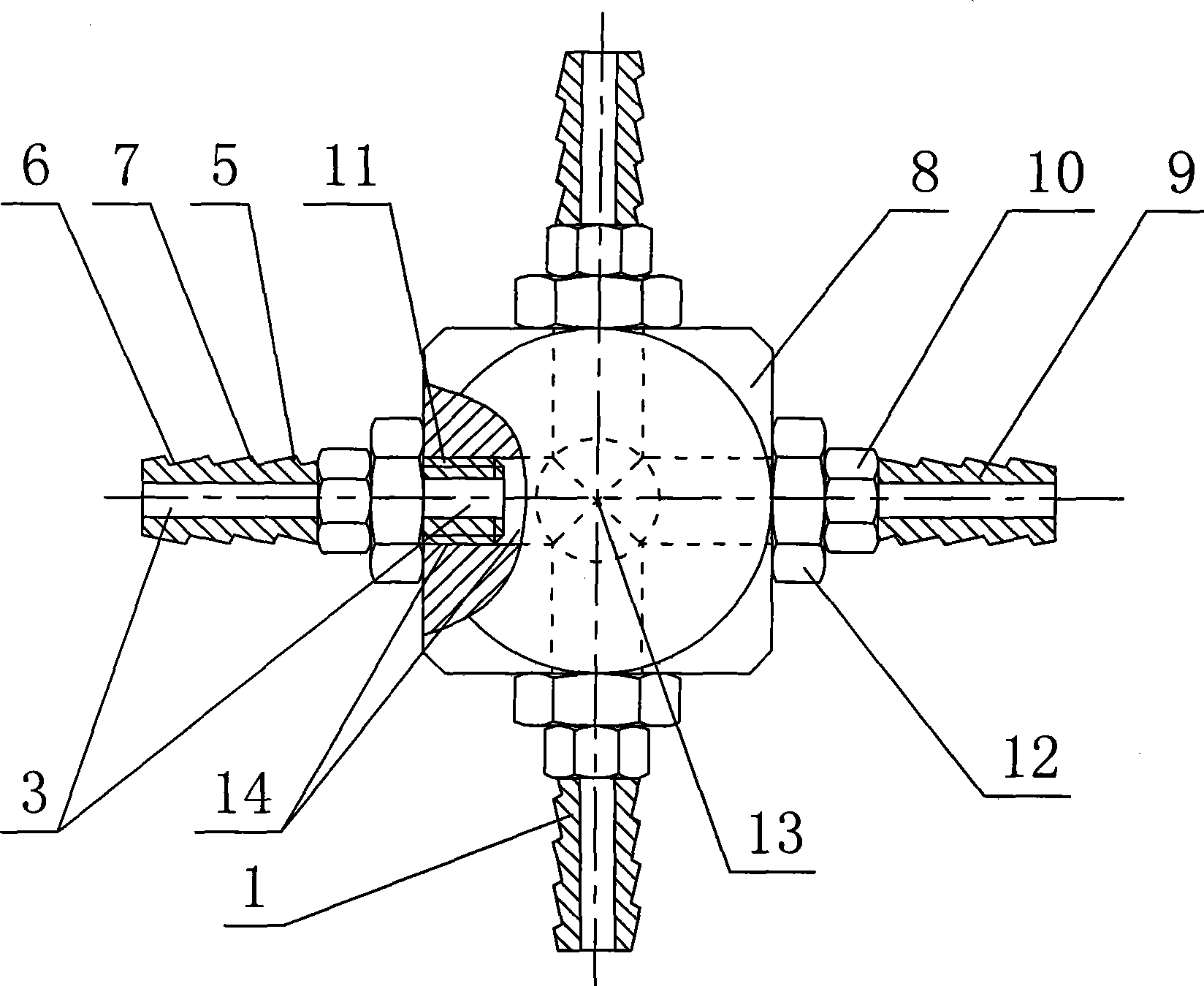

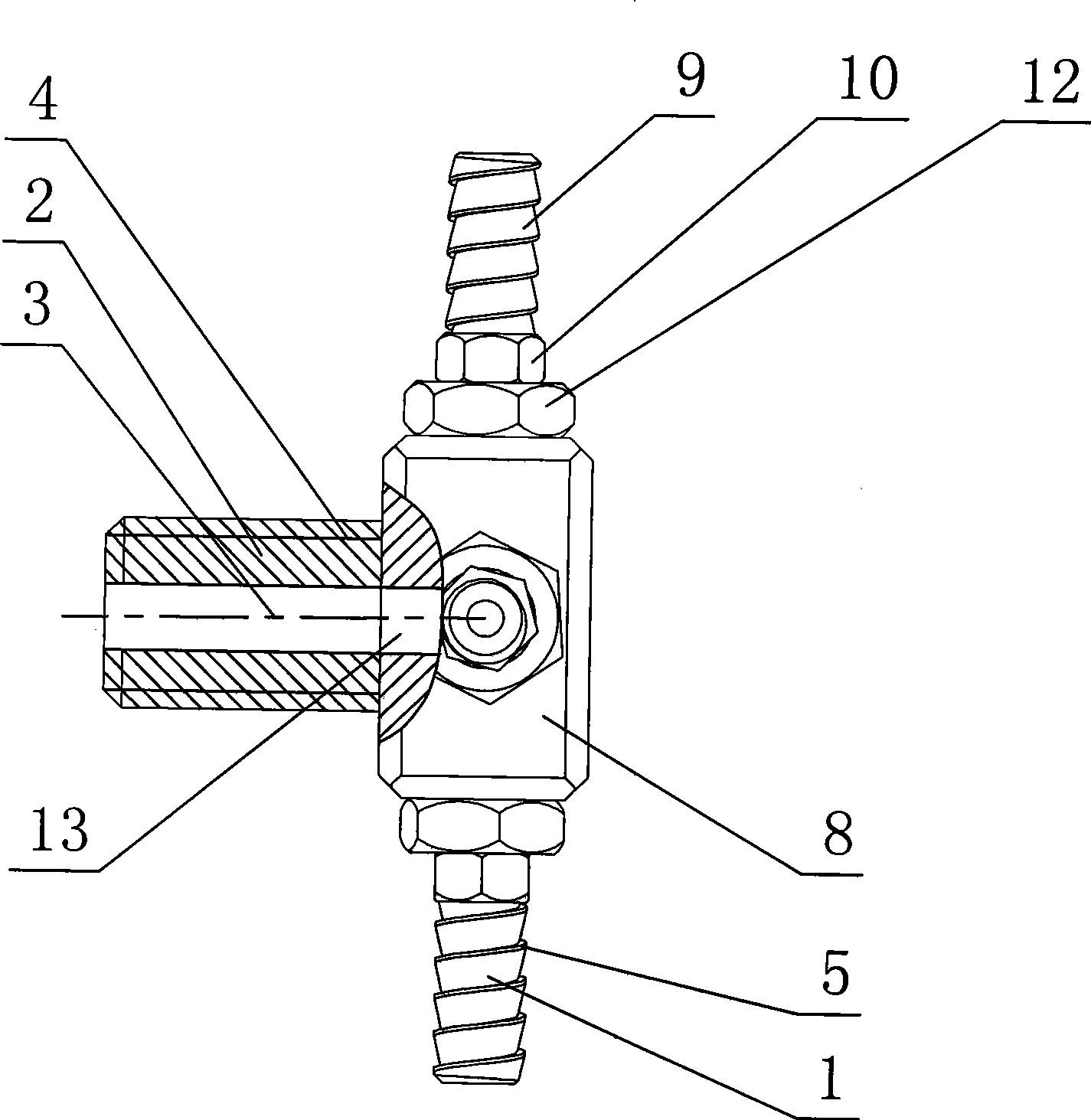

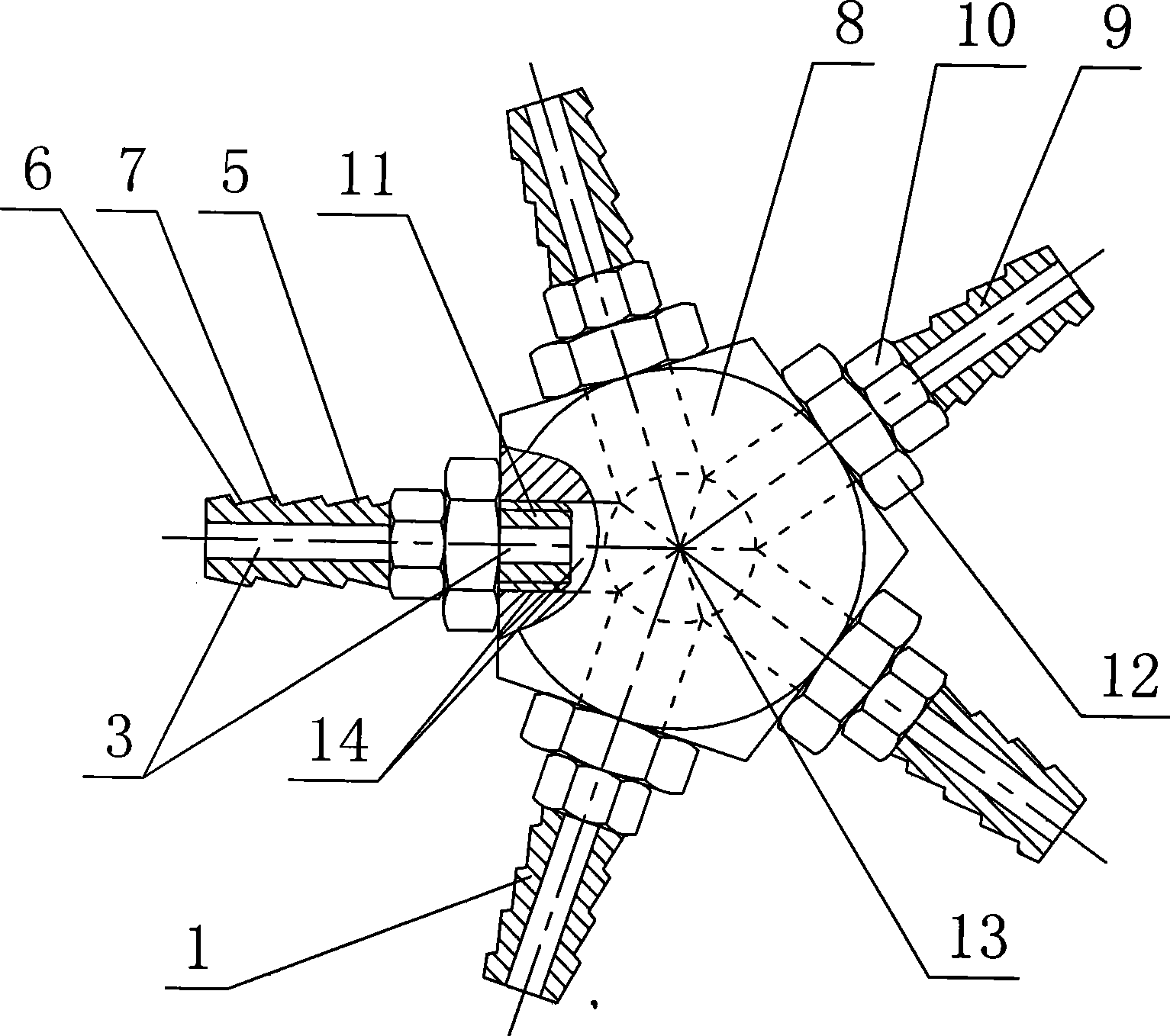

[0016] Such as figure 1 , figure 2 Shown, a kind of embodiment of multi-way joint of the present invention, it comprises a joint 2, four ends (joint nozzle) 1 and a connecting piece 8 that is substantially regular prism. The joint 2 is provided with an external thread 4, and the joint 2 is fixed on one of the two bottom surfaces of the connector 8 and is perpendicular to the bottom surface. The four ends 1 are threadedly connected to the four sides of the connector 8, that is, the four ends 1 are distributed with a bevel tooth part 9, a nut part 10 and an external thread part 11 sequentially along the axial direction, so that The external threaded parts 11 are all screwed with fastening nuts 12, and the four sides of the connecting piece 8 are provided with four threaded holes 14, and the external threaded parts 11 of the four ends 1 are res...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap