Heater

A heater and resistor technology, applied in ohmic resistance heating, instruments, electric heating devices, etc., can solve the problem of reducing the pressure resistance of the protective film 95, and achieve the effect of increasing the pressure resistance and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

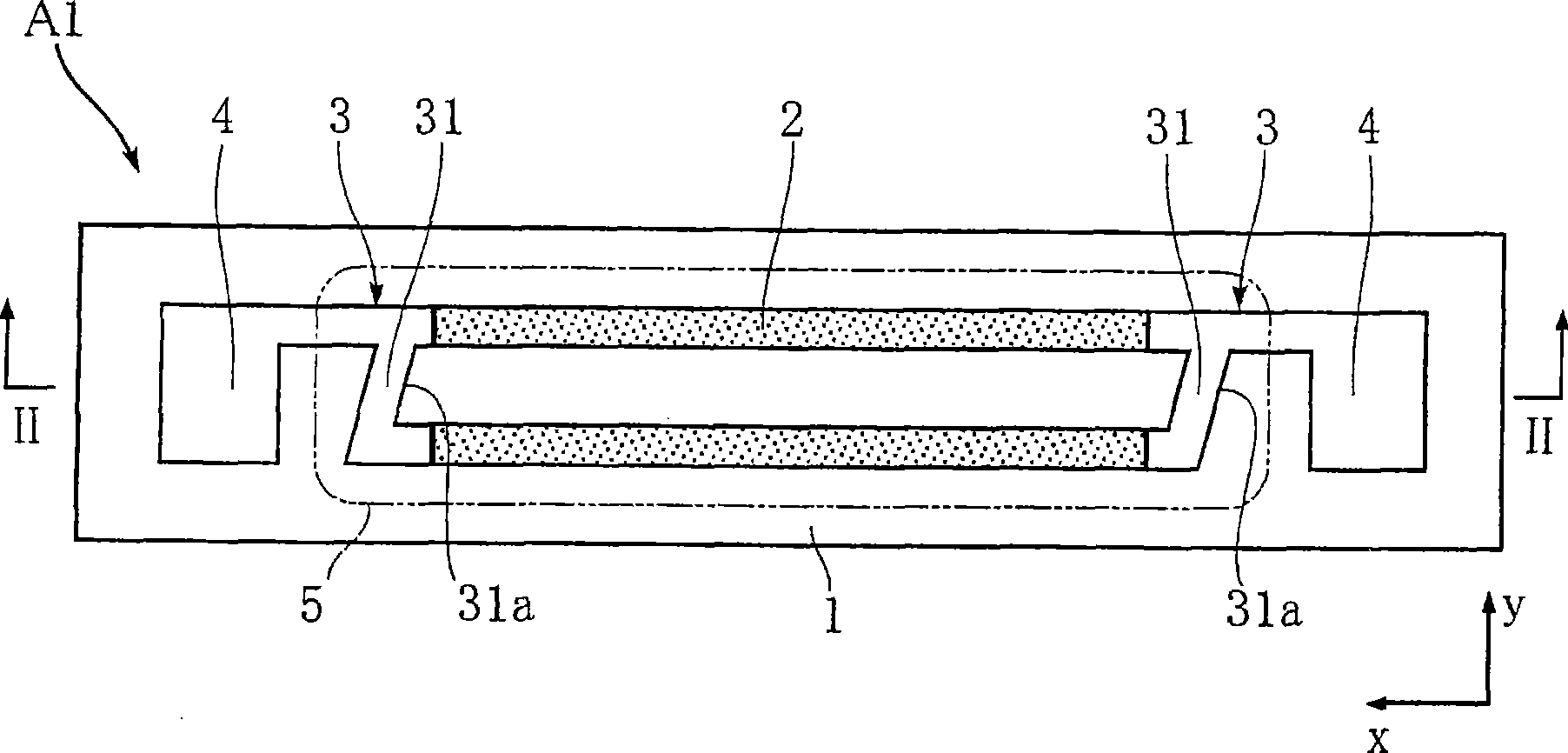

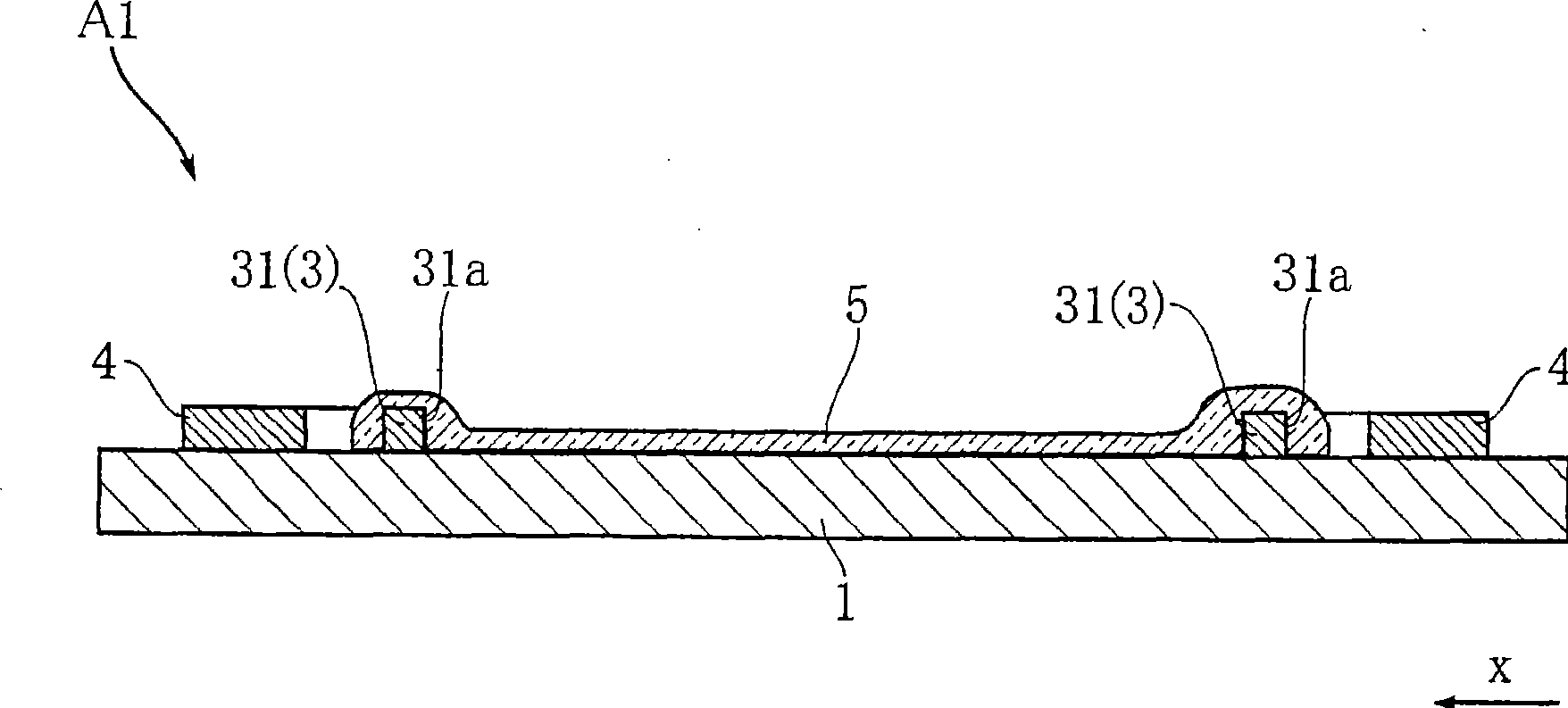

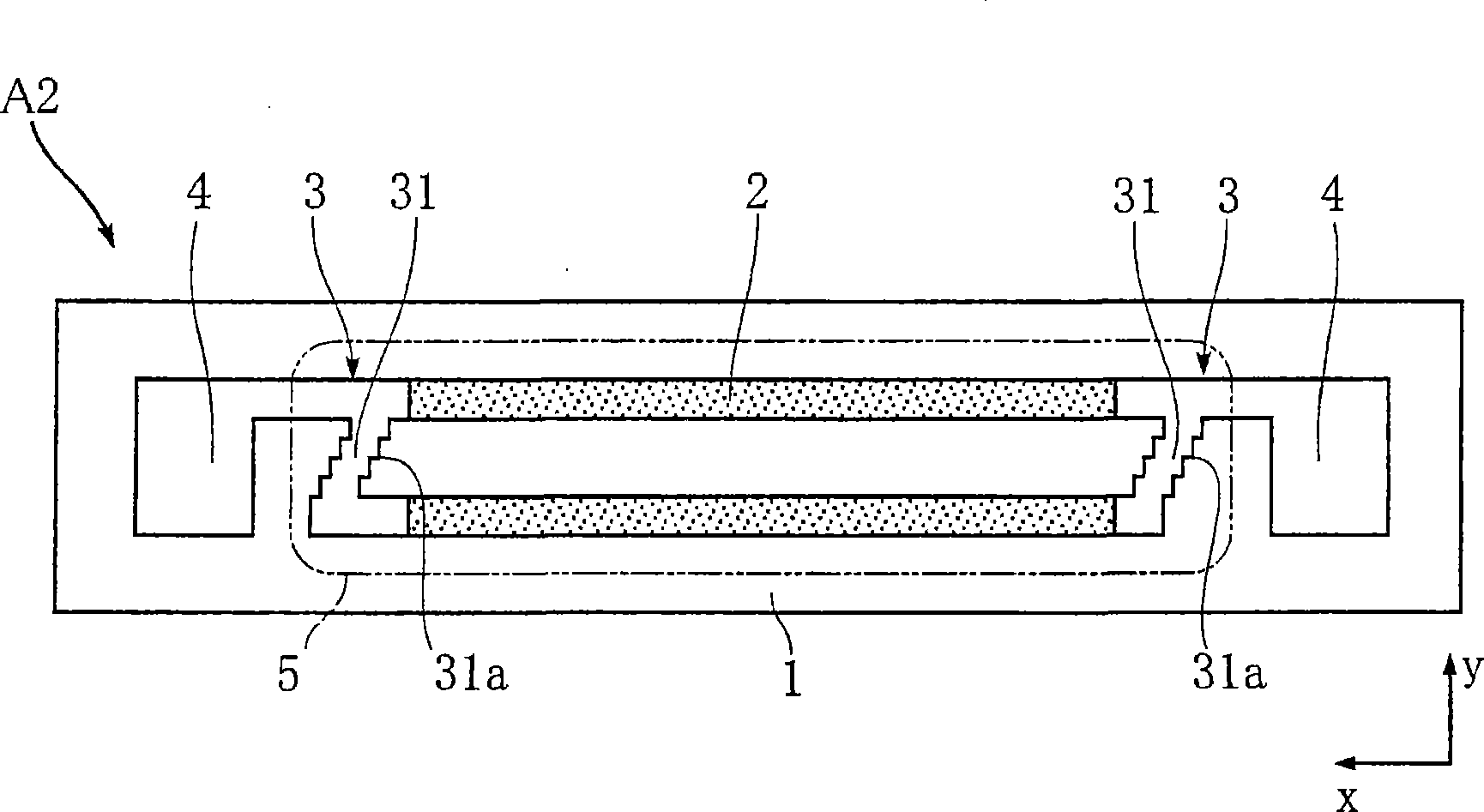

[0022] figure 1 and figure 2 A first embodiment of a heater according to the invention is shown. The heater A1 according to the present embodiment includes a substrate 1 , a resistor 2 , a wiring portion 3 , an electrode 4 and a protective film 5 . The heater A1 is used in a laser printer, for example, for heating recording paper to thermally fix the toner after the toner has been transferred onto the recording paper. It should be noted here that, for ease of understanding, the protective film 5 is drawn as figure 1 the imaginary line.

[0023] The substrate 1 is elongated and rectangular, and is made of insulating material. Examples of insulating materials include AlN and Al 2 o 3 .

[0024] The resistor 2 is formed on the substrate 1, and includes two strips in this embodiment. These strips extend in direction x, are parallel to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com