Pump for conveying a medium and lubricating system containing the same

一种润滑剂、介质的技术,应用在介质输送领域,能够解决缩短使用寿命、机器加快磨损、耗费调整等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

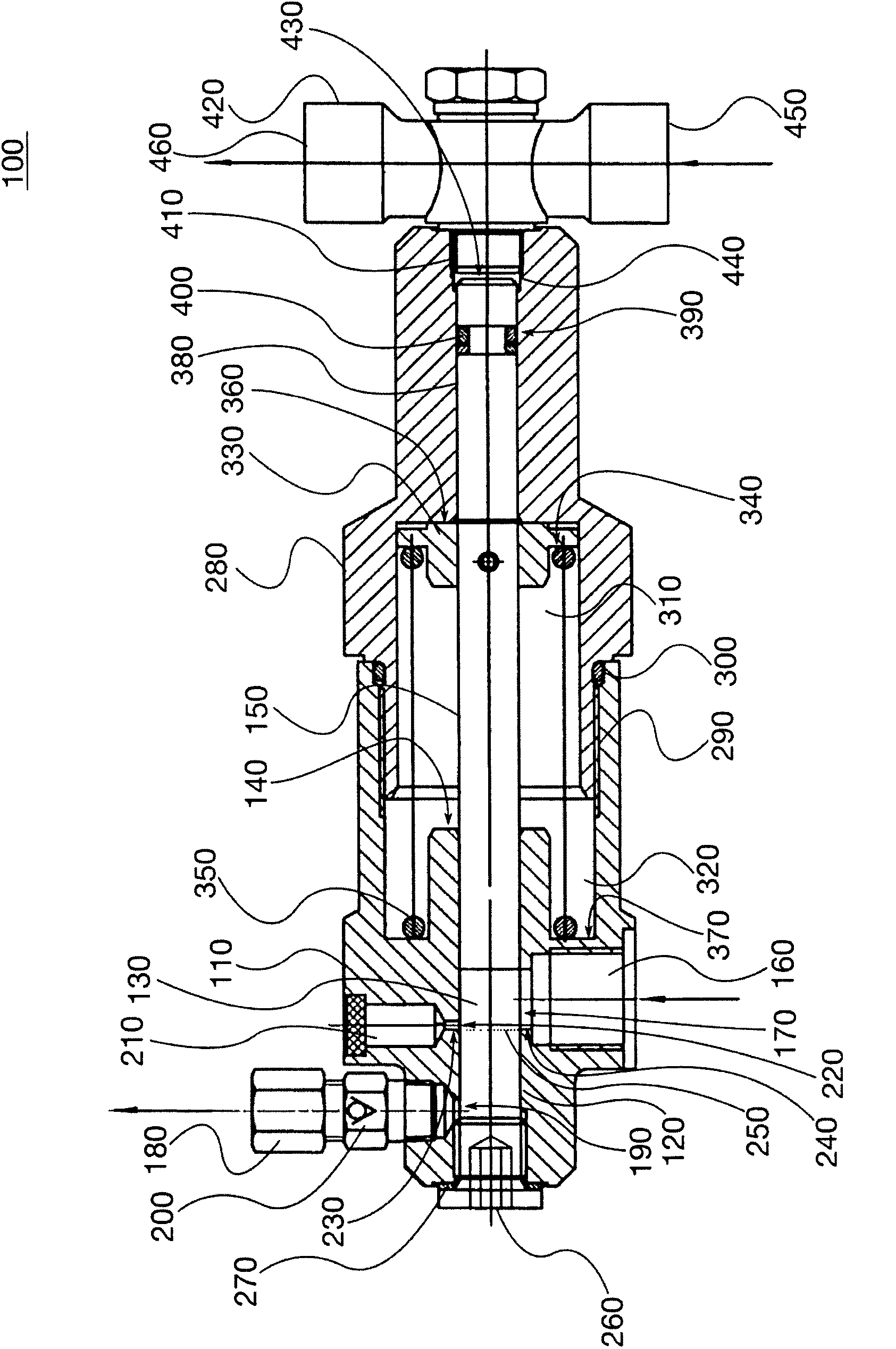

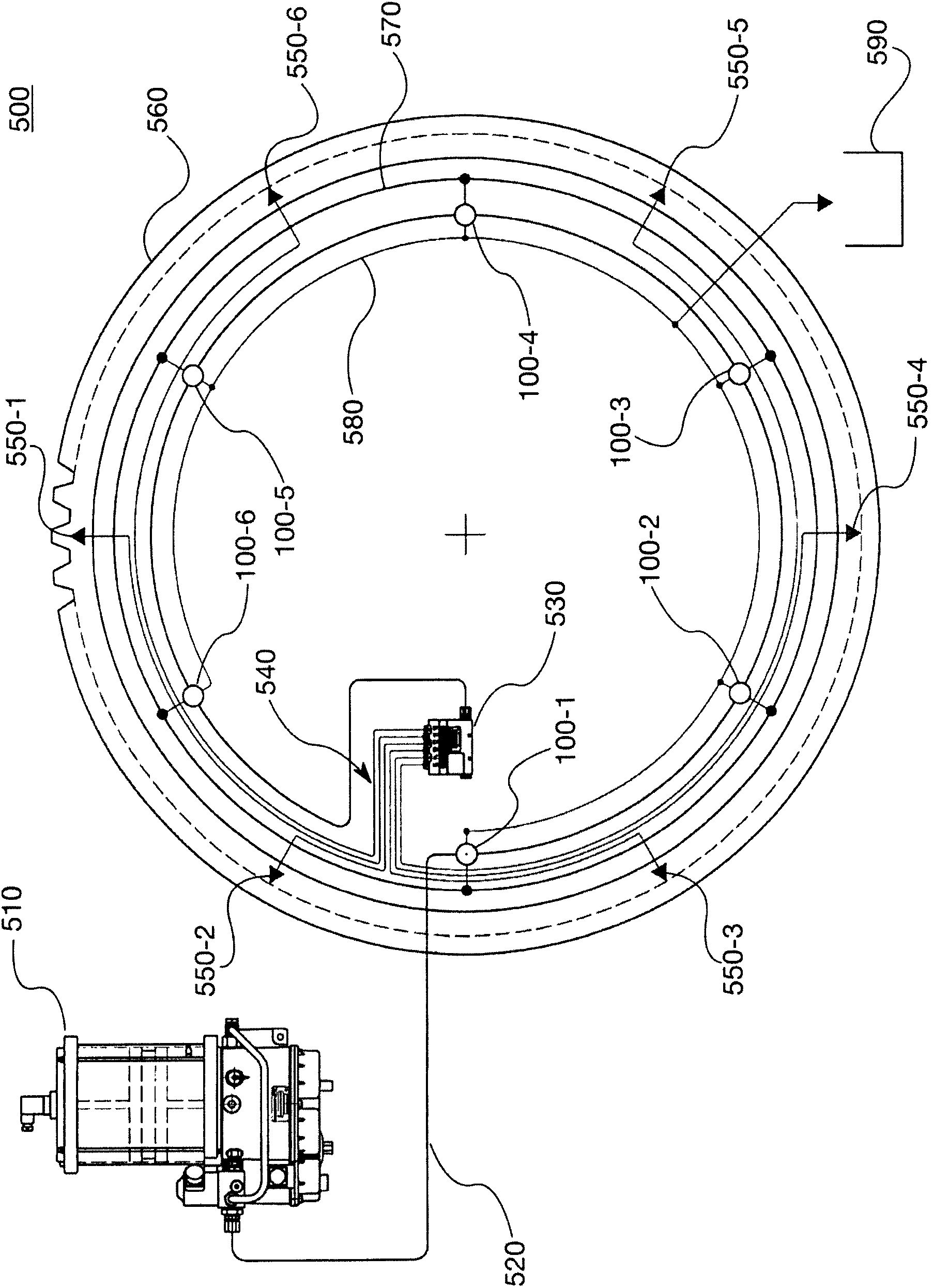

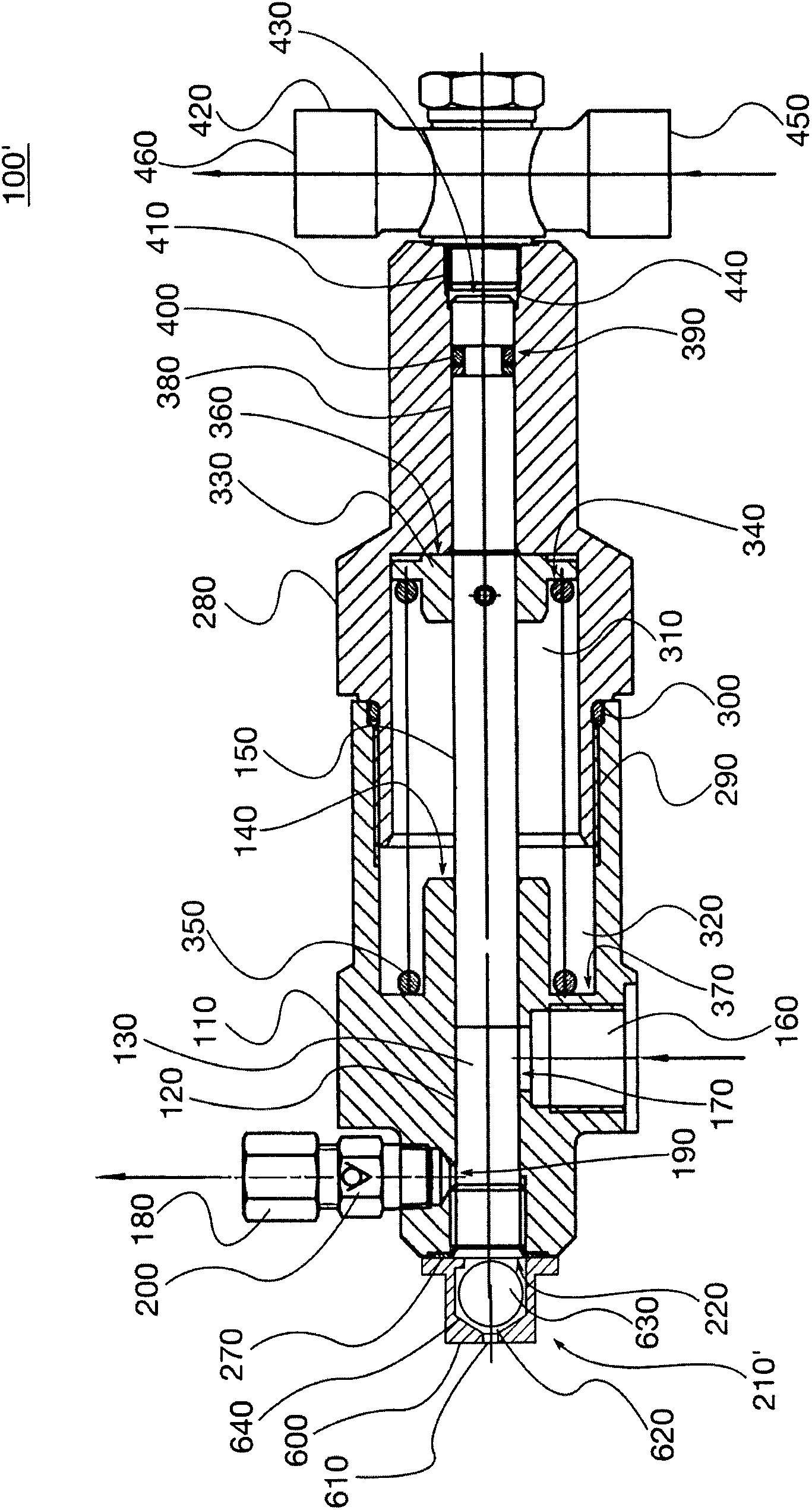

[0020] The following will be based on Figure 1 to Figure 3 Before proceeding to a detailed explanation of embodiments of the invention, it is first pointed out that, although the following description focuses on the embodiments in relation to these respective pumps, embodiments of the invention are in principle not limited to lubricant systems. The media mentioned in this description are usually lubricants, such as engine oil or grease, but embodiments of the invention are in principle not limited to these media. For example, a pump according to one embodiment of the invention is also suitable for conveying another medium.

[0021] For example, a substantially incompressible liquid or another viscous substance may be used as the medium, including, but not limited to, the aforementioned greases and other emulsions. It is likewise possible to use solid substances as media, for example carbon-based fine-grained bulk materials. However, other media can also be conveyed by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com