Gas cylinder dished head shaping technique

A disc-shaped head and forming process technology, applied in the direction of manufacturing tools, metal processing equipment, gas flame welding equipment, etc., can solve the problem that the volume is not optimized, achieve good economy, reduce length, and low overall manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

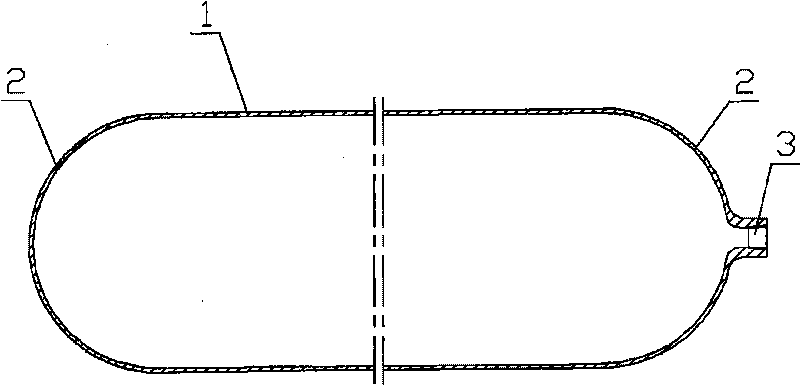

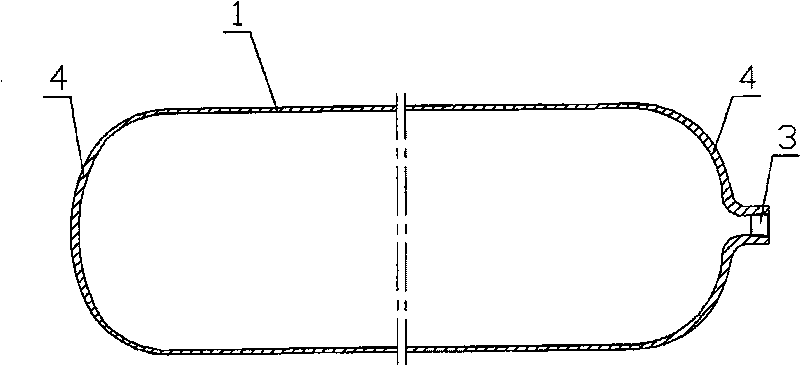

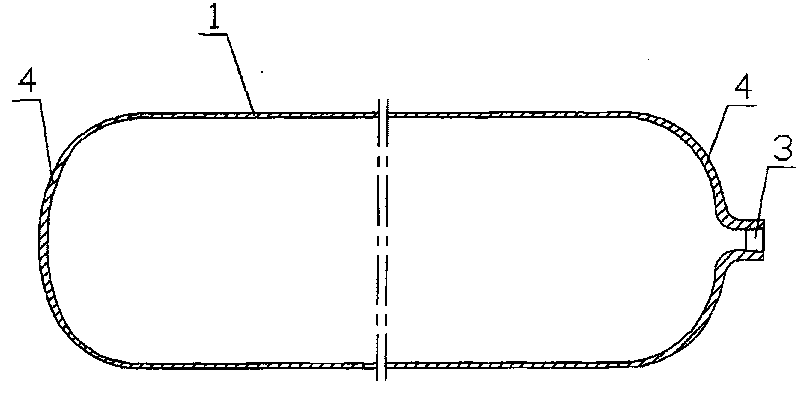

[0029] The invention discloses a manufacturing process of a wound gas cylinder steel liner with a disc-shaped head. Such as figure 2 As shown, the steel liner of the wound gas cylinder includes a liner body 1 with dish-shaped heads 4 at both ends, and an opening 3 is provided on one of the dish-shaped heads. The disc-shaped head is used to replace the traditional hemispherical head to reduce the length of the head and increase the volume of the cylinder with the same length, so that the volume of the cylinder can be increased to 70L, and the volume of the cylinder with the same diameter can be increased by 3%. Wherein, the manufacturing process includes a bottom closing process and a closing process. The so-called bottom closing process and closing process are the molding processes of the two dished heads. The difference is that the closing process refers to the forming process of the dished head with an opening, and the bottoming process refers to the forming process of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com