Thermal forming of molded piece

A technology for thermoforming machines and parts, which is applied in the field of thermoforming of molded parts, and can solve problems such as difficulty in resetting, occupying floor space, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

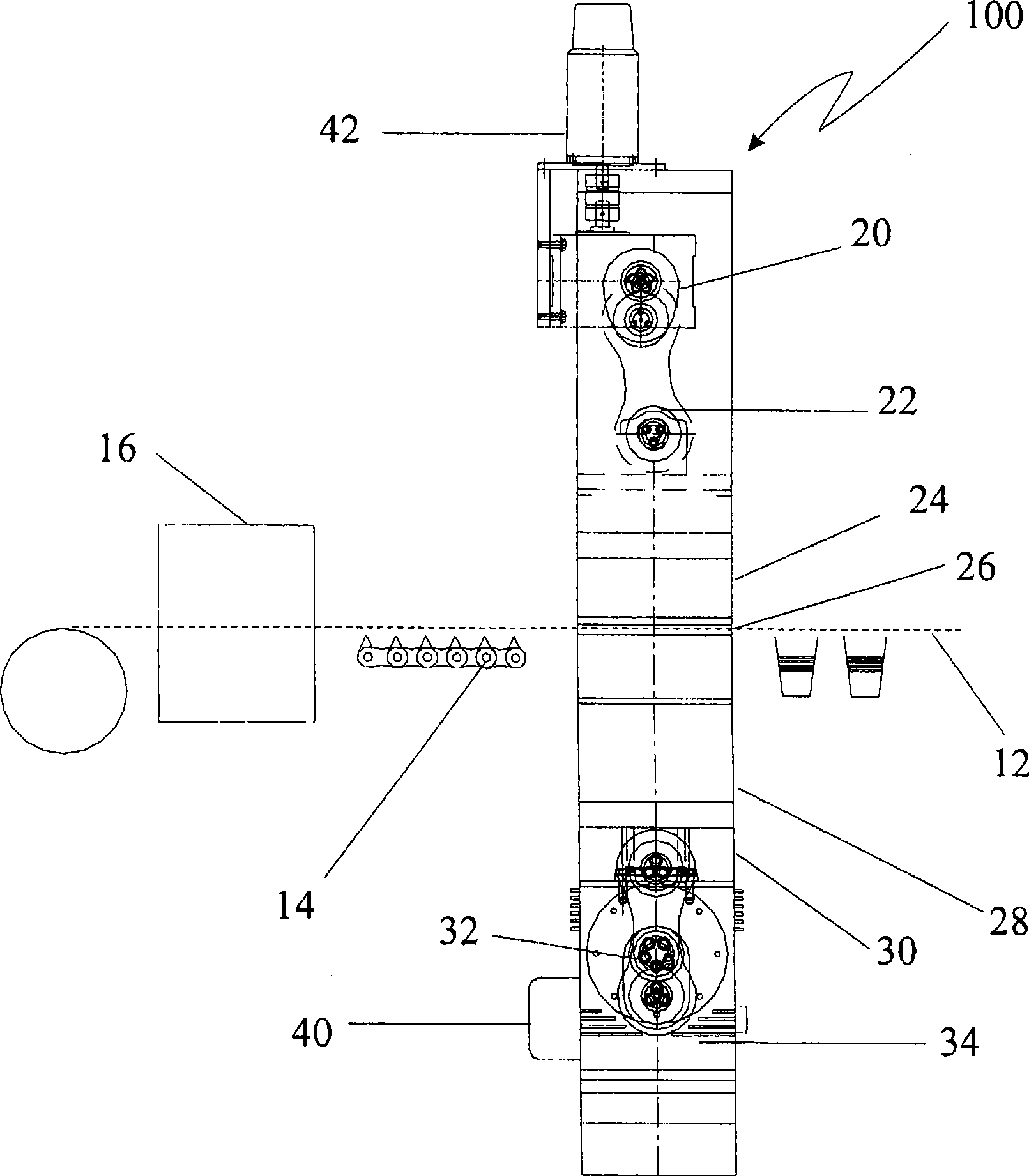

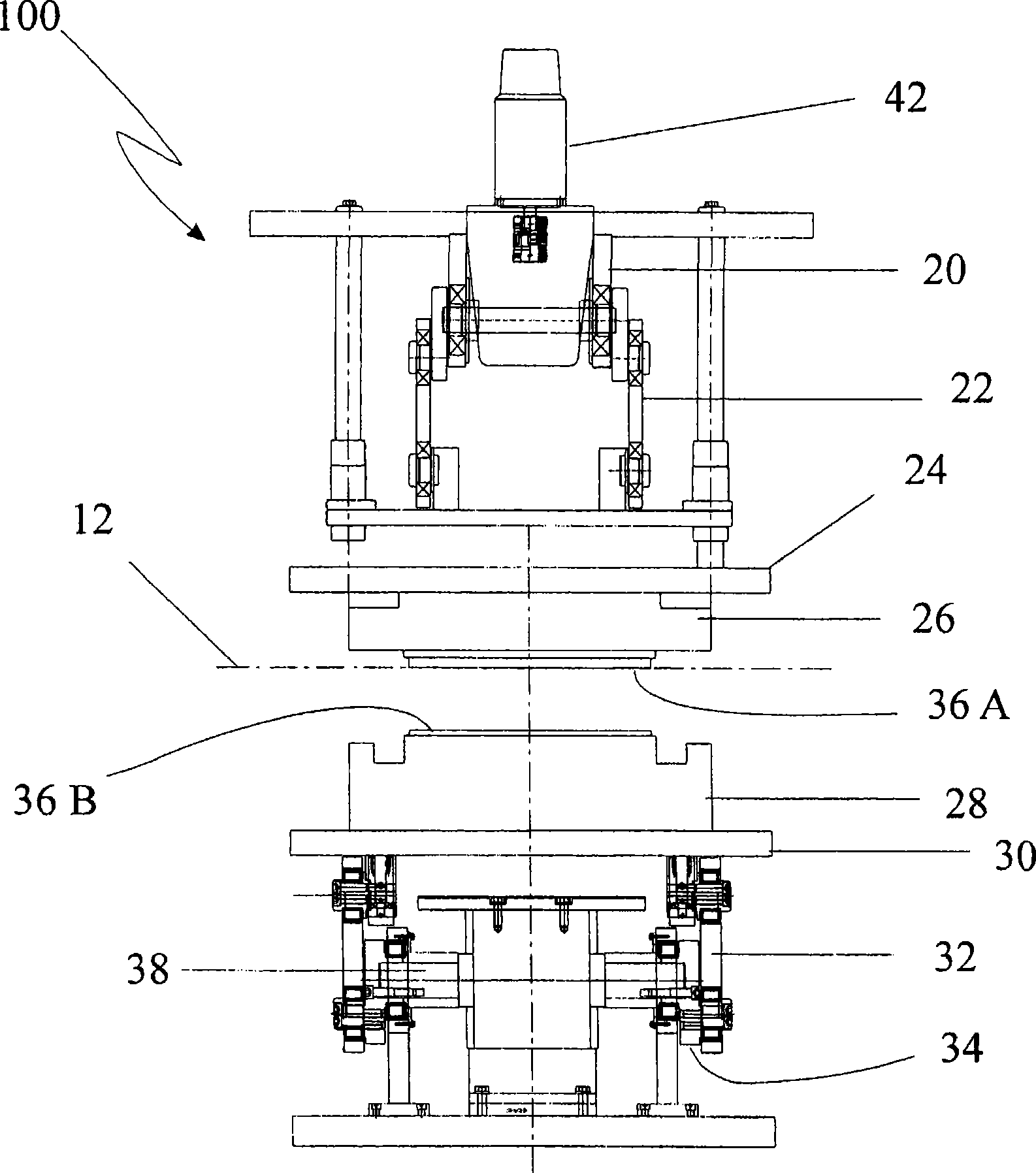

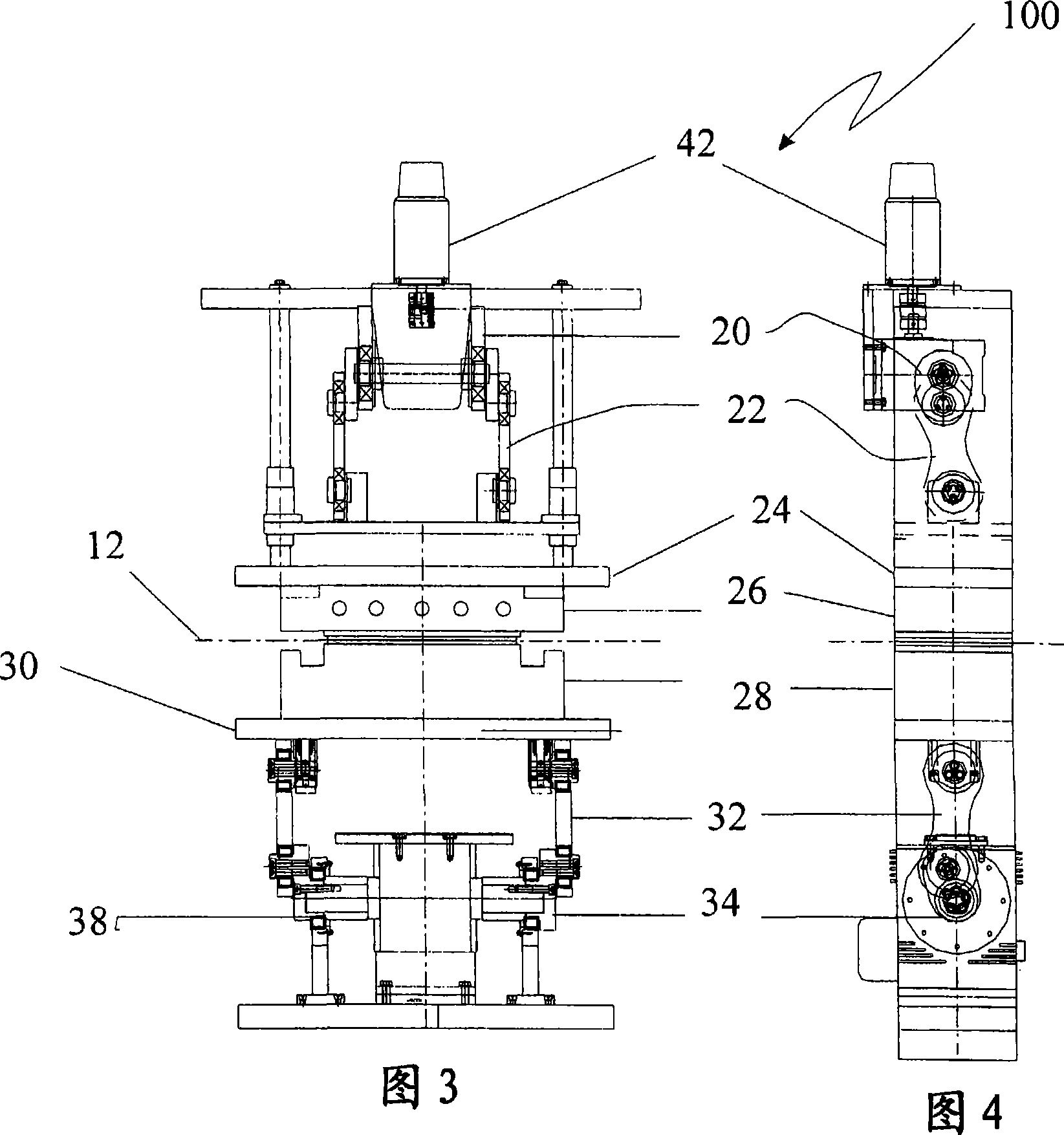

[0056] Referring to the drawings, a thermoforming machine according to the invention is indicated generally by the reference numeral 100 .

[0057] The machine includes a frame (not shown) in which an upper platen 24 and a lower platen 30 are disposed. A mold half 26 serving as a press-in male mold is mounted on the upper platen 24 . The other mold half 28 serving as a female mold part is mounted on the lower platen 30 . The upper pressing plate 24 is provided with a driving unit 42 , and the lower pressing plate is provided with a driving unit 40 . A connection mechanism in the form of a spline unit 20 and a link 22 is provided between the drive unit 42 and the upper platen 24 . Another connecting mechanism in the form of a spline unit 34 and a link 32 is provided between the drive unit 40 and the lower platen 30 . An in-mold cutting tool is provided in the machine 100 consisting of two parts 36A on the male press-in die part 26 and 36B on the female die part 28 .

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com