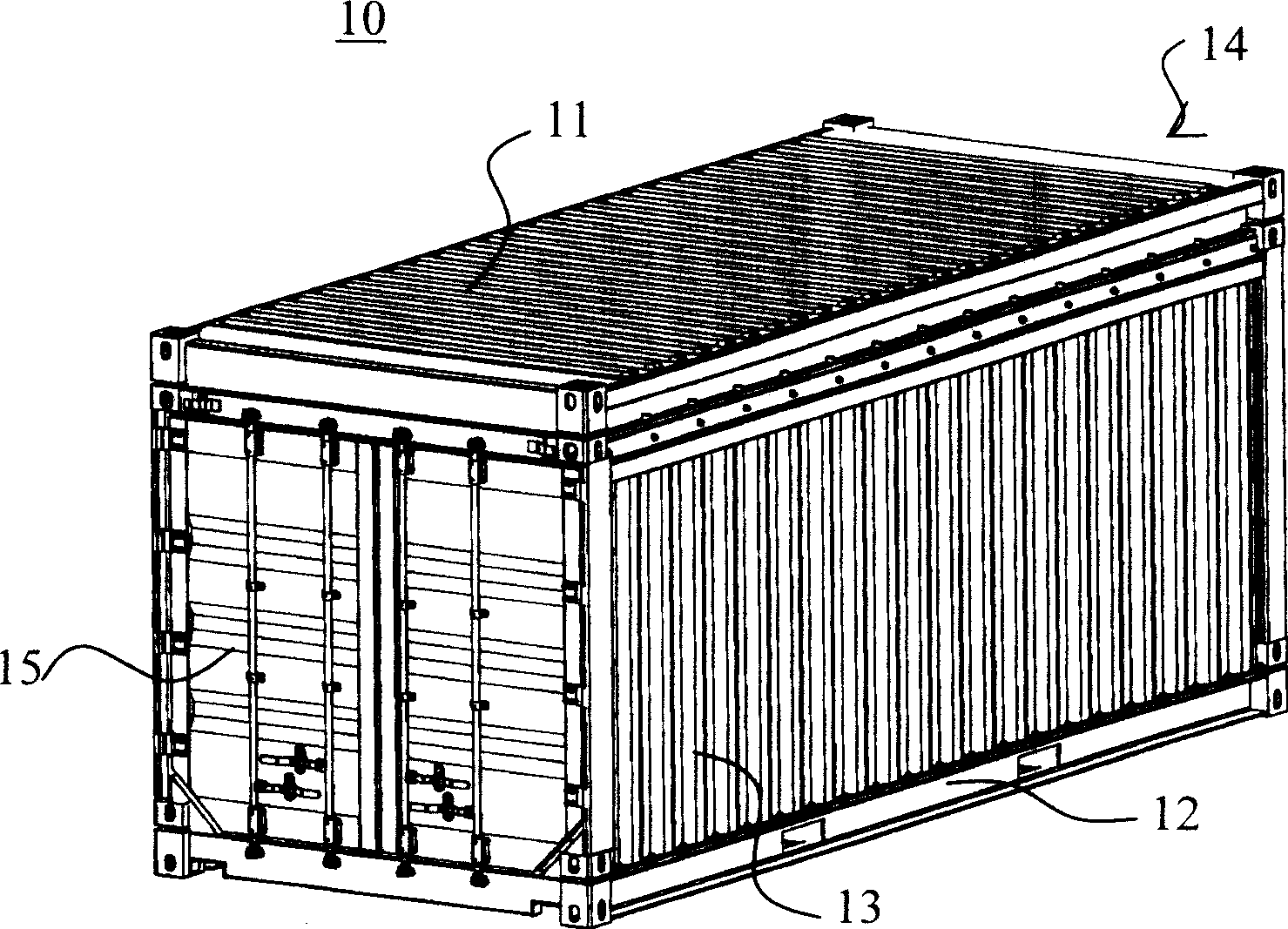

Container assembly method, container assembling apparatus and setting method thereof

An assembly method and assembly device technology, applied in packaging, transportation and packaging, containers, etc., can solve the problems of life safety threats to operators, reduce production efficiency, increase container production costs, etc., achieve safe and reliable storage space, and improve safety , The effect of improving production efficiency and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

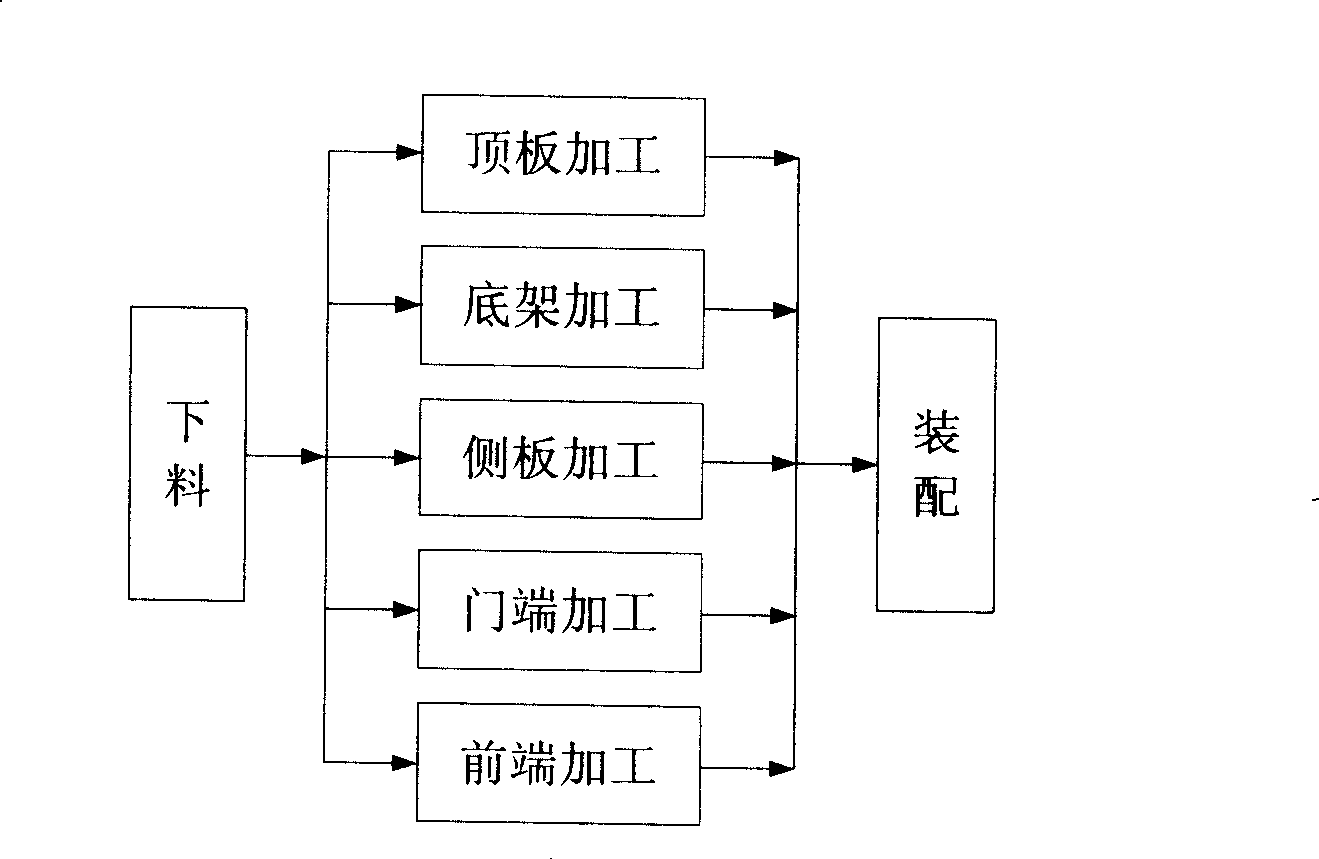

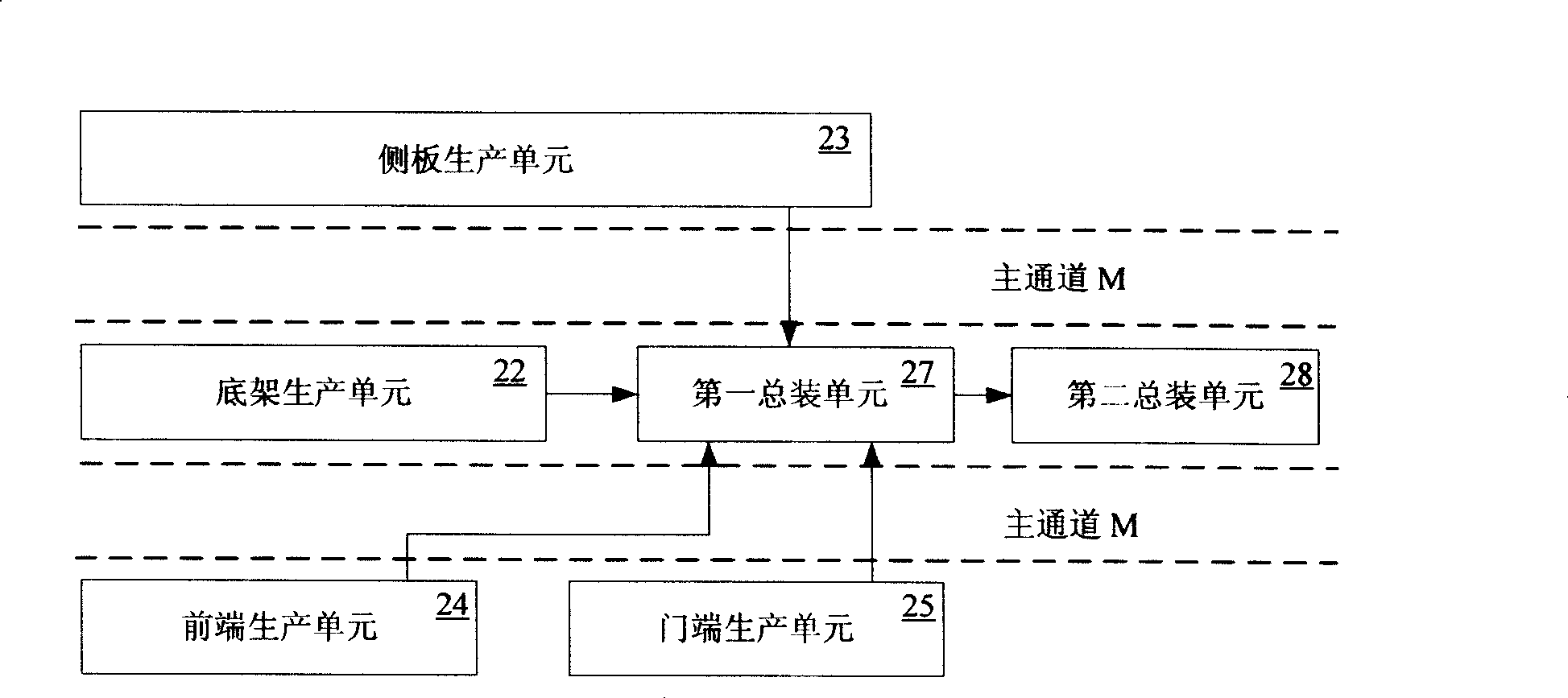

[0024] Such as Figure 4 As shown, the container assembly device 100 of the present invention comprises a top plate production unit 110, a bottom frame production unit 120, a side plate production unit 130, and a front end production unit 140 for producing the top plate, bottom frame, side plate, front end and door end of the container respectively. . The door end production unit 150 also includes an assembly unit 190 for assembling the container as a whole. Wherein the roof production unit 110 is located above the assembly unit 190 .

[0025] refer to Figure 4 , Figure 5 , the chassis production unit 120 and the assembly unit 190 are preferably arranged side by side in parallel, and are located on the same side of the main passage M of the production workshop. The production directions of the two are opposite, that is, the production upstream direction of the chassis production unit 120 corresponds to the production downstream direction of the assembly unit 190 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com