Hydraulic support electrohydraulic control system and ad hoc network method thereof

A technology of electro-hydraulic control system and hydraulic support, which is applied in the direction of mine roof support, earth square drilling, mining equipment, etc., and can solve the problems of reducing the length of the working face, reducing the reliability of the system, increasing the number of relay or interface processing links, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

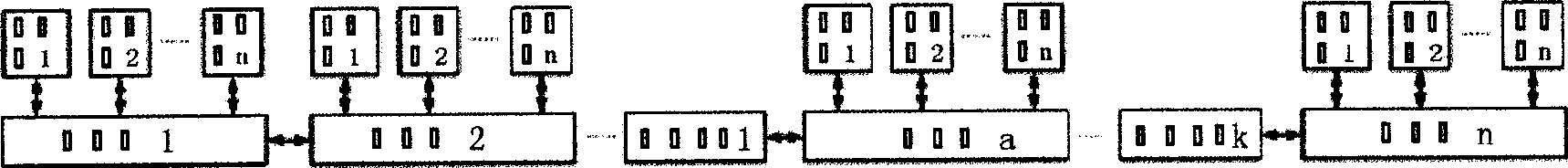

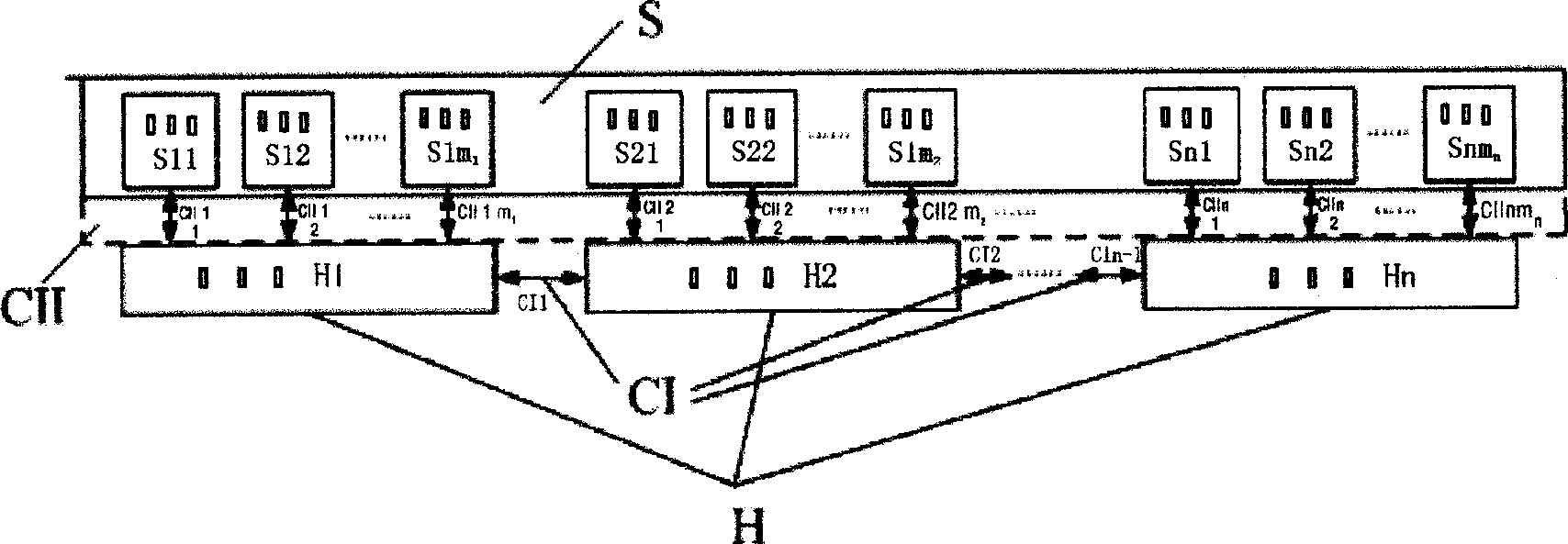

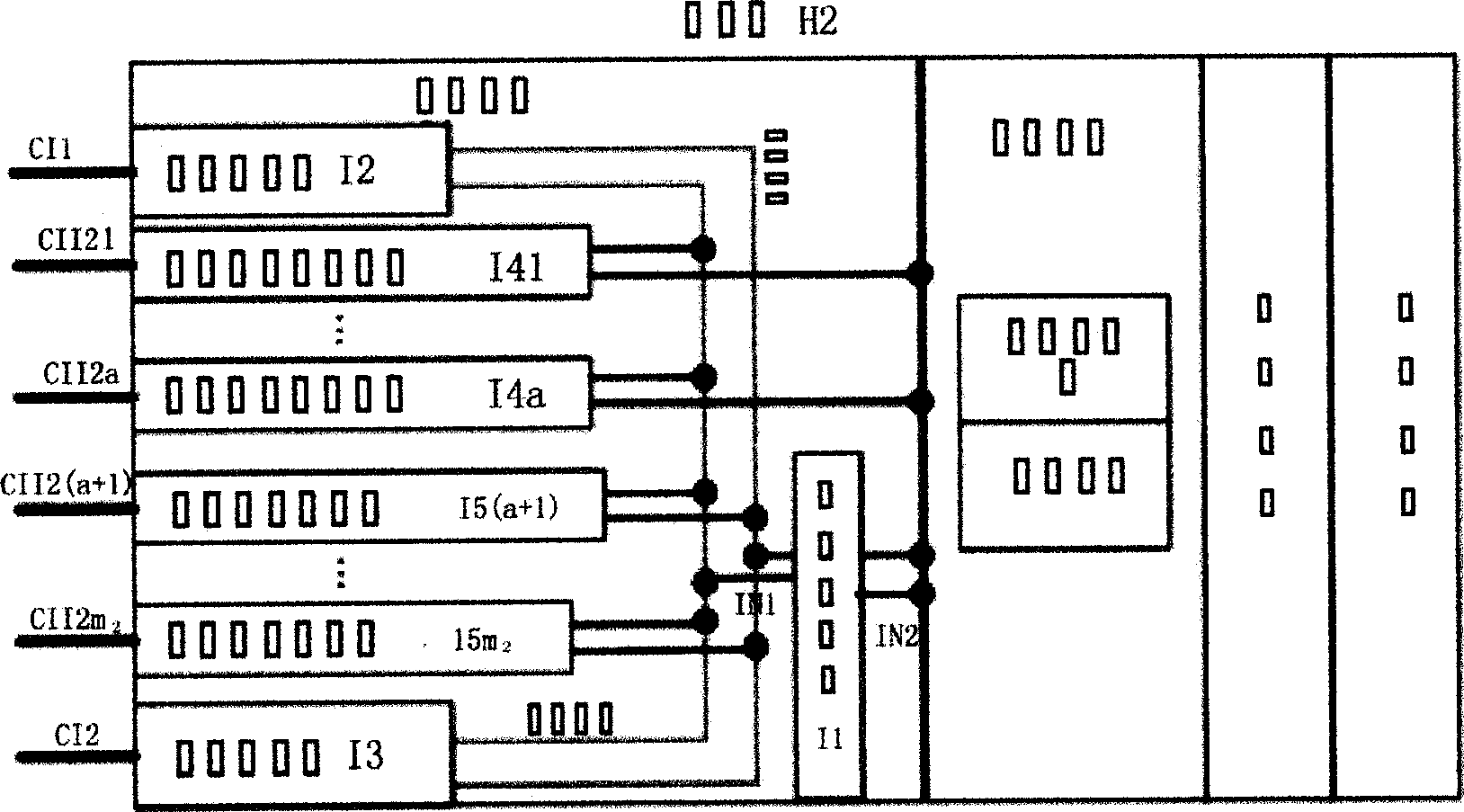

[0059] figure 2 It shows the electro-hydraulic control system of the hydraulic support provided by the present invention. The control system includes a master device group H composed of master devices H1~Hn, and any master device Hx in the master device group H includes slave devices Sx1~Sxm x , all slave devices form a slave device group S, where n, m x is a natural number, x is any natural number from 1 to n; the control system also includes the power supply and communication medium group CI between the master equipment and the power supply and communication medium group CII between the master and slave equipment, among which the master equipment The power supply and communication media group CI includes power supply and communication media CI1~CIn-1, any master device Hx in the master device group H and the slave devices Sx1~Sxm contained therein x Between power supply and communication medium CIIx1~CIIxm x For connection, the power supply and communication media between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com