Electrified lubricator of high voltage isolating switch

A high-voltage isolating switch and lubricator technology, which is applied in the direction of manual lubricant supply, engine components, engine lubrication, etc., can solve the problems of heavy pulling and closing, no conditional maintenance of insulating oiling tools, and less movement of transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

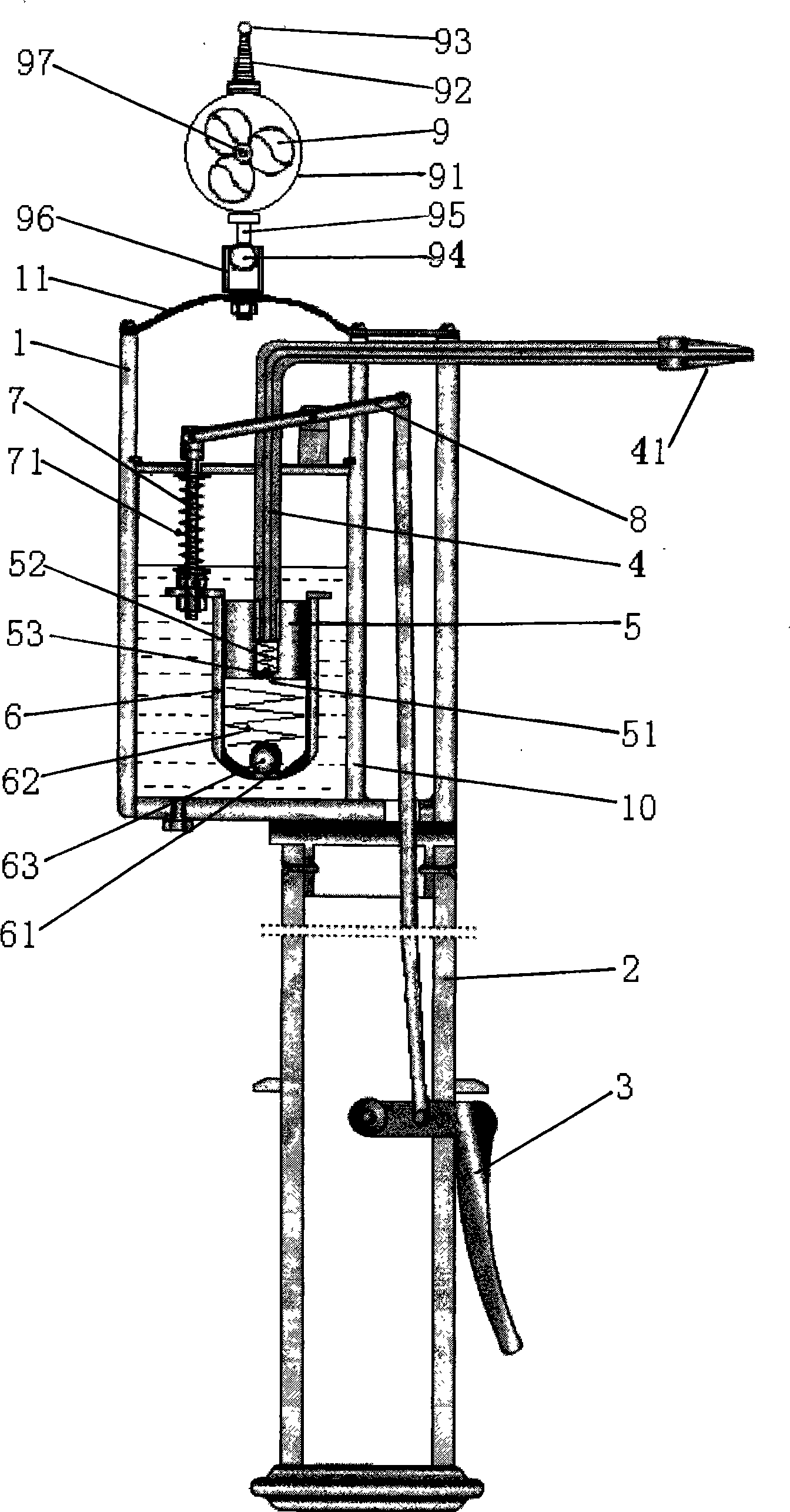

[0009] Such as figure 1 As shown, the live oiler for high-voltage isolating switch of the present invention has an insulating oil pot 1 as its main body, an insulating rod 2 is installed below the insulating oil pot 1, and an insulating refueling handle 3 is provided at the handheld part of the lower end of the insulating rod 2. An insulating pull rod 10 is arranged, and the lower end of the pull rod 10 is connected with the refueling handle 3 . The exposed end on the insulating oil pot 1 is set as an oil outlet nozzle 41, and the oil outlet nozzle 41 is connected with the oil outlet pipe 4 of the oil pressure mechanism inside the oil pot, and the suction end of the oil outlet pipe 4 of the oil pressure mechanism inside the oil pot is equipped with a fixed piston 5 and a movable The cylinder body 6 has an oil inlet hole 61 on the bottom surface of the movable cylinder body 6, and an oil inlet spring 62 and an oil inlet steel ball 63 are arranged between the piston 5 and the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com