Magnetic powder inspection apparatus

A technology of magnetic particle flaw detection and current coil, which is applied in the direction of material magnetic variables, etc., can solve the problems of poor consistency of manual winding, unsuitable for batch inspection, cumbersome manual winding, etc., and achieve the effect of good and reliable contact, increased flexibility, and uniform magnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

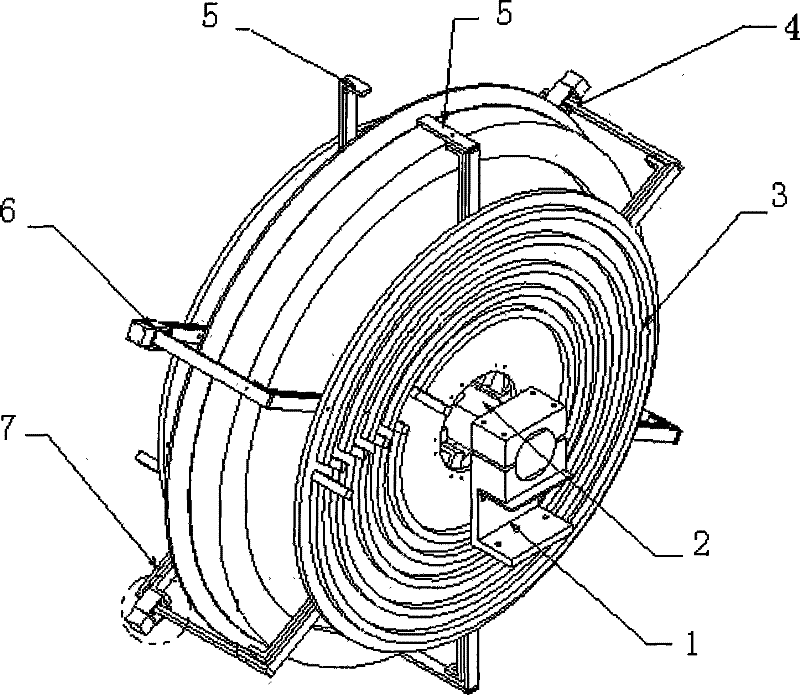

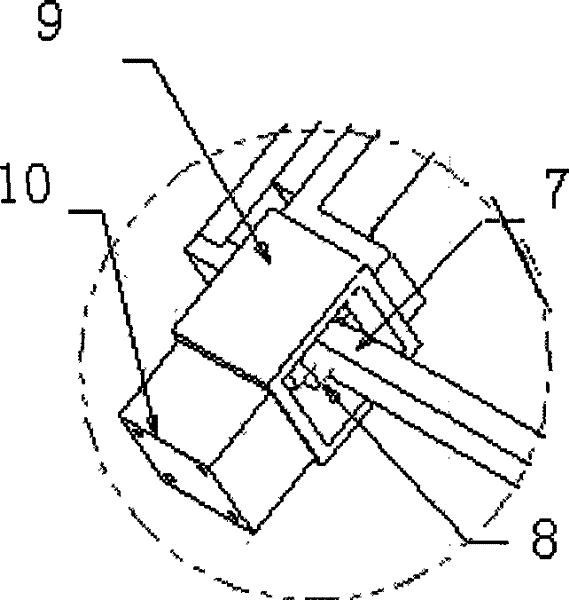

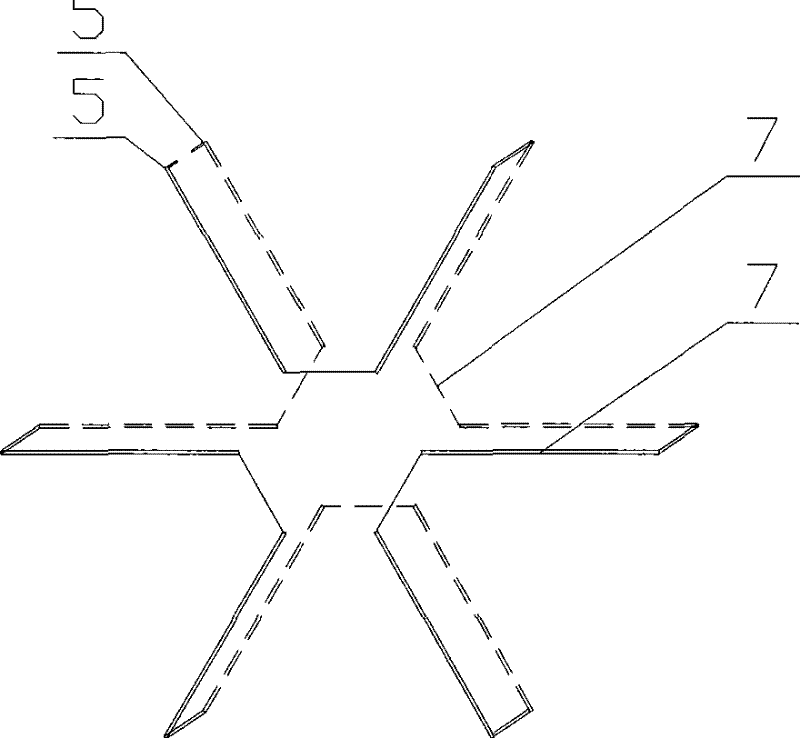

[0027] Such as figure 1 As shown, the workpiece to be detected is a ring-shaped workpiece with a diameter of 1250mm, a thickness of 210mm, and an inner hole of 230mm, such as a locomotive wheel, a wheel center and other ring-shaped workpieces. The produced fork-shaped current coil 7 has a fork-shaped shape, and the projection of each turn is U-shaped. Two groups of fork-shaped current coils 7 are respectively fixed on the inside of two epoxy resin plates with a thickness of 15mm on both sides of the workpiece to be detected. , the epoxy resin plate is connected with the movable mechanism of the flaw detection device through the fixed seat 1, which not only plays a role of fixing but also plays the role of inter-turn insulation. The ring current coil 3 is also fixed with an iron core detecting magnetic bar 2 on the fixing base 1 . The fork-shaped current coils 7 on the left and right sides are connected through the terminal 4 on the outer diameter surface of the workpiece to b...

Embodiment 2

[0029] The workpiece to be inspected is an extra large annular workpiece with a diameter of 2530mm, a thickness of 110mm, and an inner hole of 1850mm, such as the inner and outer rings of the pitch bearing. Fork-shaped current coil, its shape is fork-shaped, and the projection of each turn is U-shaped. Two sets of fork-shaped current coils are respectively fixed on the inside of two epoxy resin plates with a thickness of 15mm on both sides of the workpiece to be tested. The epoxy resin plate It is connected with the movable mechanism of the flaw detection device through the fixed base 1 . The fork arm length of the above-mentioned fork-shaped current coil is 80 mm, the length of the fork back rod is 850 mm, the length of the fork arm of the right fork-shaped coil is 450 mm, the length of the fork back rod is 1350 mm, and the fork tip contacts of the left fork-shaped coil are equipped with 15 mouth-shaped The bracket adopts 15 small air cylinders to drive the meshing and pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com