Fluorescent flat optical waveguide solar cell photovoltaic power generation system

A photovoltaic power generation system and planar optical waveguide technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as high cost and reduced efficiency, and achieve the effects of reducing consumption, large equivalent light concentration, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

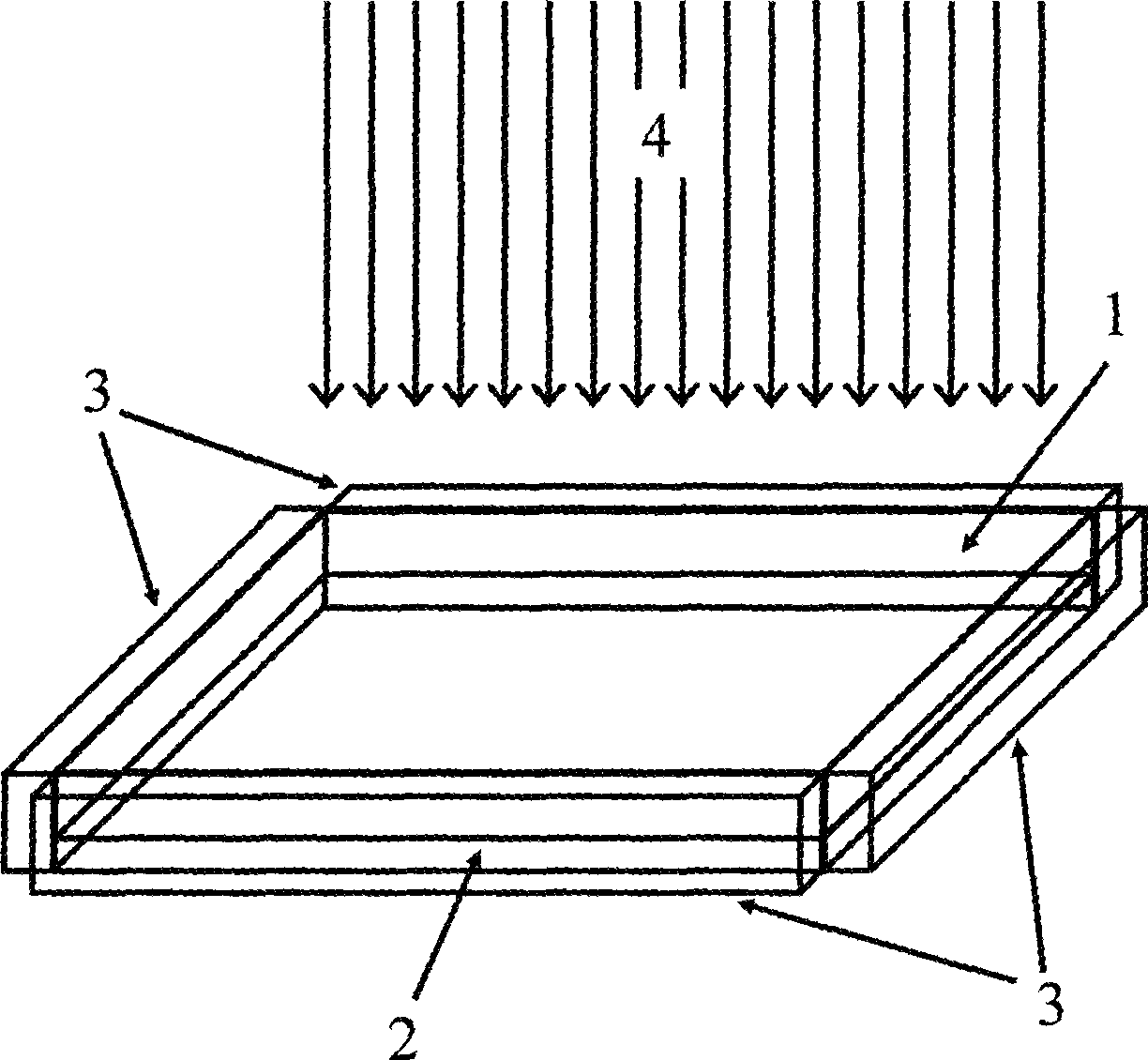

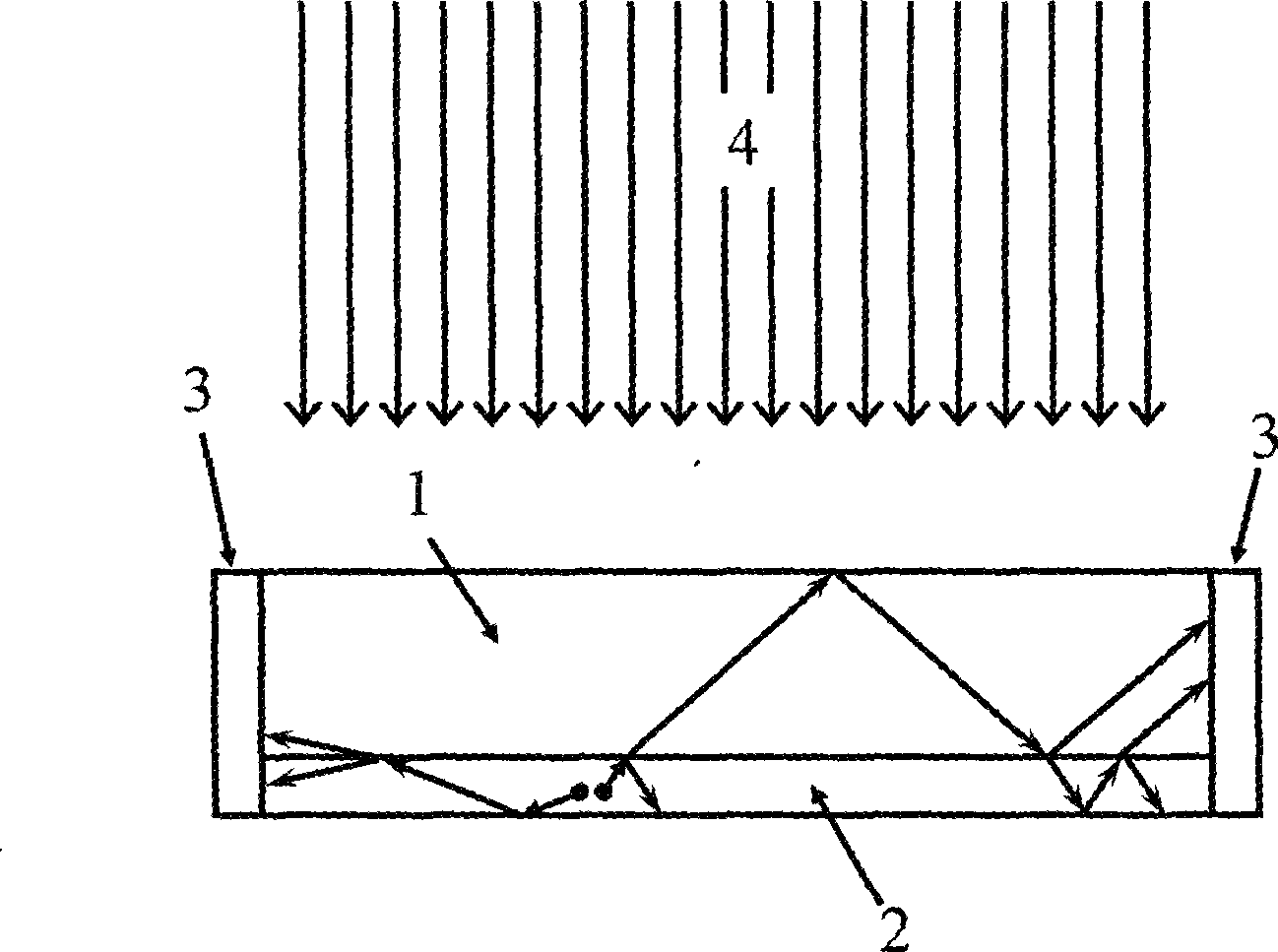

[0045] see figure 1 , image 3 and Figure 5 , 5wt% rare earth co-luminescence organic complex (Eu 0.05 , La 0.4 )(DBM) 3 Phen (rare earth dibenzoylmethane o-phenanthroline complex) mixed with polymethyl methacrylate (PMMA) matrix, spin-coated on ordinary glass 1 with a thickness of 3 mm, a length of 1.5 m and a width of 0.5 m to form a 10 micron Thick fluorescent material layer 2 . Aluminum (Al) reflective film 7 is coated on two 1.5m sides and one 0.5m side of glass 1, and silicon solar energy is bonded to the other 0.5m side with UV-3129 ultraviolet curing adhesive from Shenzhen Xinyi Adhesive Co., Ltd. battery3. The refractive index of ordinary glass and PMMA is about 1.5, and the numerical aperture of the corresponding planar optical waveguide is 0.75 (that is, 75% of the fluorescence enters the transmission mode). The fluorescent material absorbs sunlight in the 300nm-400nm band (ultraviolet part, accounting for about 5% of the total solar radiation), radiates flu...

Embodiment 2

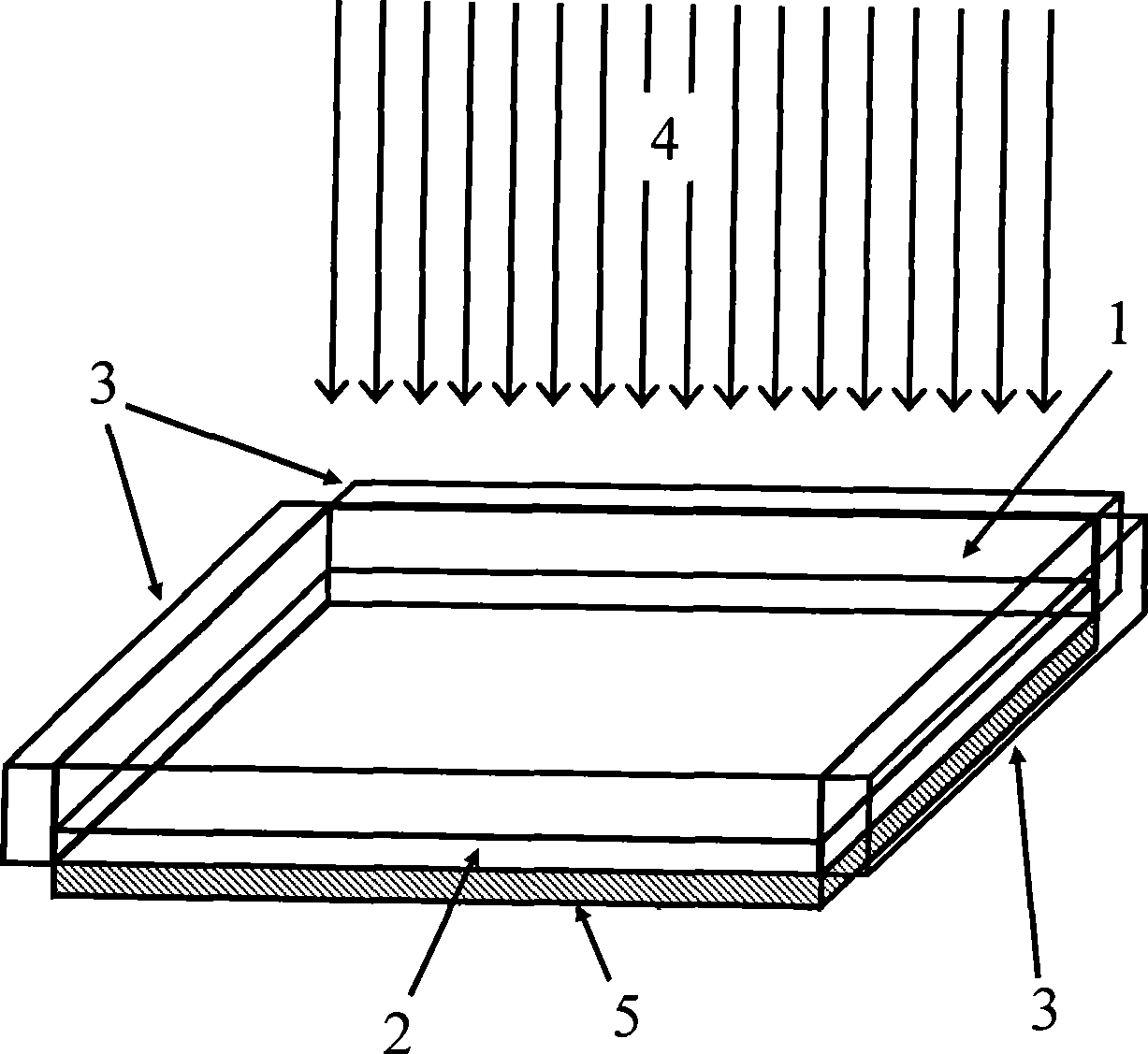

[0052] see Figure 6 and Figure 7 , 5wt% rare earth co-luminescence organic complex (Eu 0.05 , Tb 0.1 )(DBM) 3 Phen (rare earth dibenzoylmethane phenanthroline complex) mixed with polymethyl methacrylate (PMMA) matrix, spin-coated on a polyethylene (PE) transparent sheet 1 with a thickness of 0.1 mm, a length of 1 m, and a width of 20 cm , forming a fluorescent material layer 2 with a thickness of 10 micrometers. The lower surface of the fluorescent material layer 2 is plated with an aluminum (Al) reflective film 5, and the upper surface of the transparent sheet 1 is provided with a high-efficiency light-transmitting, reflective (Eu 0.05 , Tb 0.1 )(DBM) 3 The photonic crystal 8 of Phen fluorescent wavelength, two 1m sides of transparent plate 1 and a 20cm side are coated with aluminum (Al) reflective film 7, and the other 20cm side uses the UV-3129 ultraviolet light of Shenzhen Xinyi Adhesive Industry Co., Ltd. Curing the adhesive to bond the gallium arsenide solar cel...

Embodiment 3

[0060] see Figure 4 , in order to further reduce the amount of solar cells, on the basis of Example 1, parallel concave-convex grooves 6 can be set on the surface of the fluorescent planar light guide, so that the fluorescence can only be transmitted to the two sides along the direction parallel to the concave-convex grooves 6, that is The solar cells 3 are only arranged on the two sides of the fluorescent planar light waveguide perpendicular to the concave-convex groove 6, thereby reducing the usage of the solar cells from four to two. Further, one of the two solar cells perpendicular to the concave-convex groove 6 can also be replaced with a side reflective film 7, such as Figure 4 Shown in 7. The side reflective film 7 reflects back the fluorescent light reaching this side and couples it into the solar cell from the other side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com