Food baking machines

A technology for roasting machines and food, applied in roasting devices, electric heating devices, electrical components, etc., can solve the problems of unsafe use, increased energy consumption, hot air leakage, etc., and achieve the effect of reducing heat dissipation and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

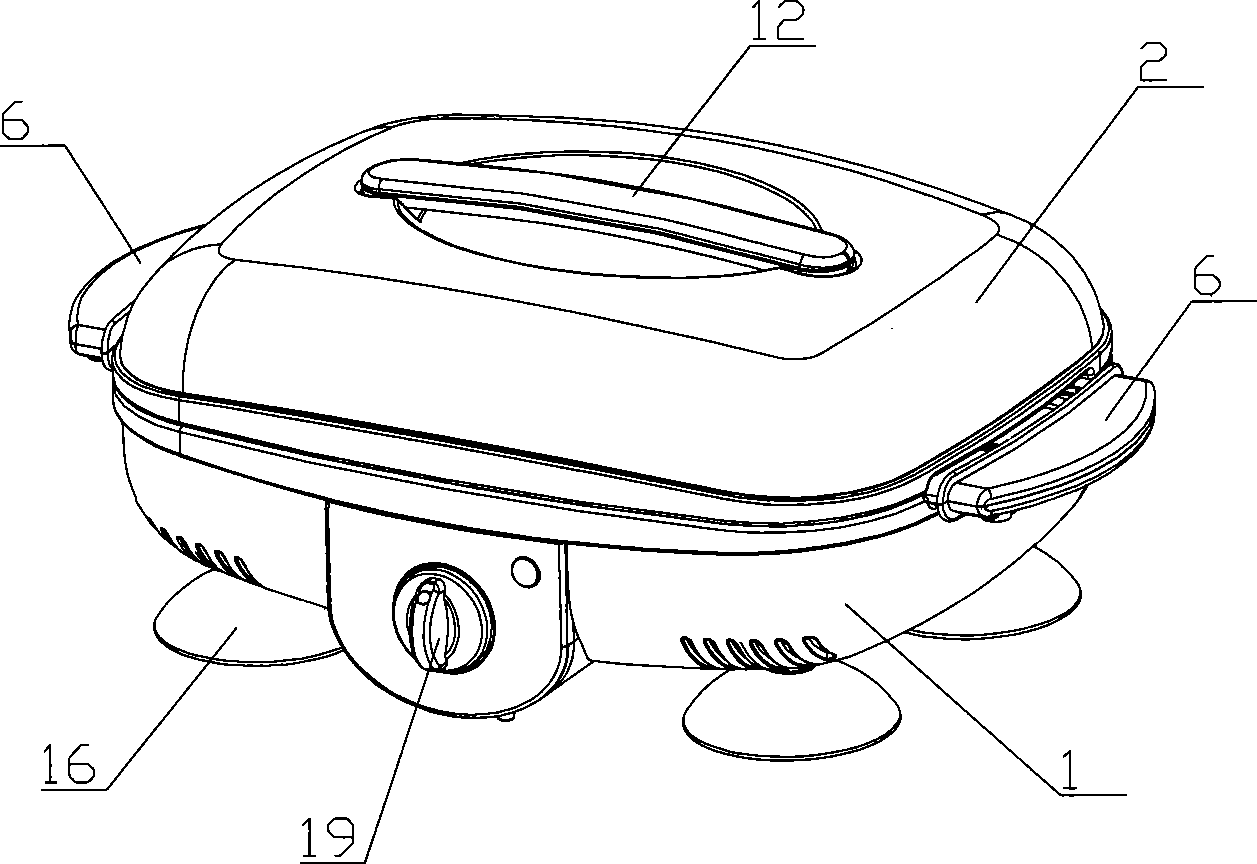

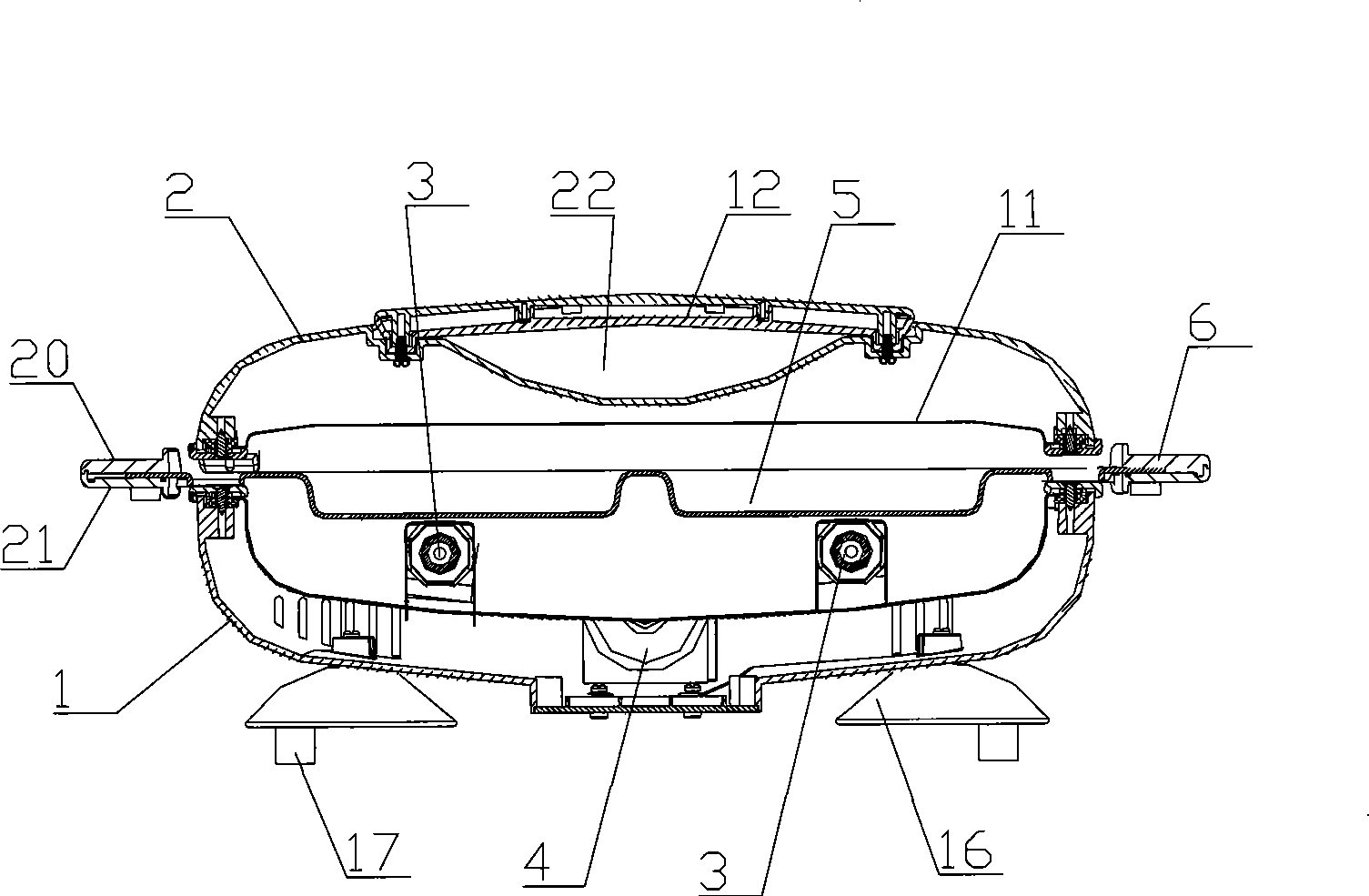

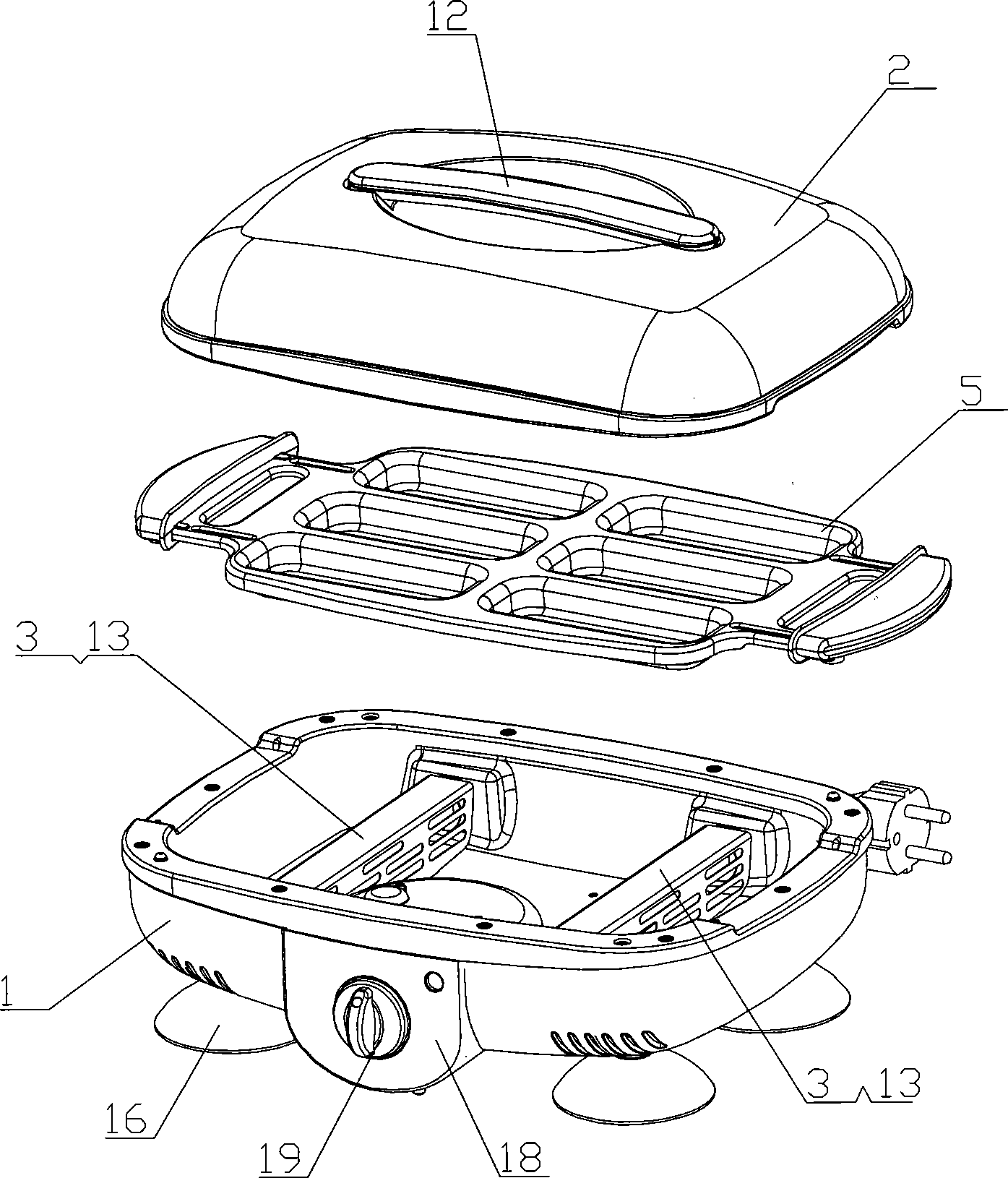

[0027] Such as Figure 1 to Figure 6 As shown, a food roasting machine, the base 1 and the upper cover 2 are closed to form a heating space, and an electric heating device 3 is provided in the heating space (the electric heating device 3 in this embodiment adopts a quartz tube). The device 3 is electrically connected to the circuit board 4; a baking pan 5 is provided between the base 1 and the upper cover 2, and a handle 6 is provided on the baking pan 5, and the handle 6 at least partially protrudes from the heating space and is exposed .

[0028] Wherein, the handle member 6 includes a connecting portion 7 close to the baking pan 5 and a handle portion 8 away from the baking pan 5, and a handle member upper cover 20 and a handle member lower cover 21 are provided on the handle member 8. There are heat-proof conduction holes 9 to enhance heat insulation and anti-scalding effects, and there are two handles 6, which are respectively arranged on the two side ends of the baking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com