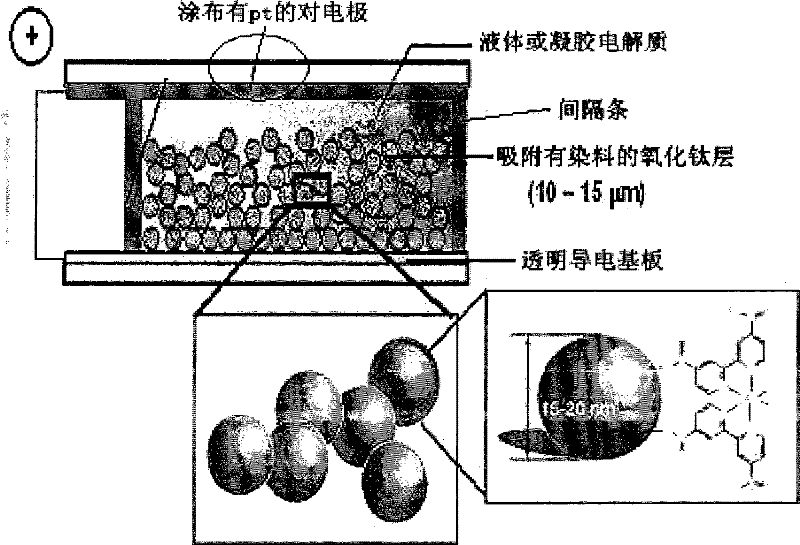

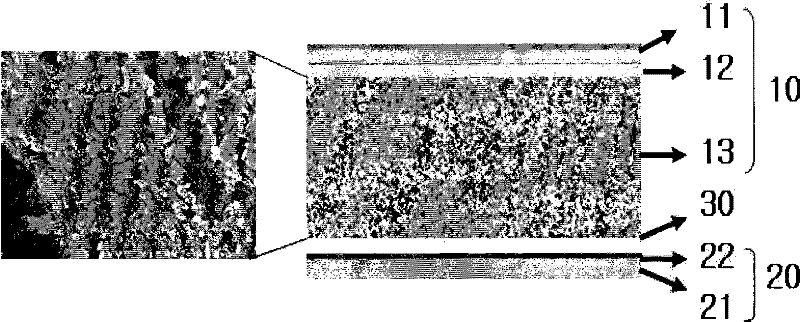

Dye-sensitized solar cell with metal oxide layer containing metal oxide nanoparticles produced by electrospinning and method for manufacturing same

A solar cell, oxide layer technology, applied in secondary cells, final product manufacturing, sustainable manufacturing/processing, etc., to achieve high porosity and improve photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

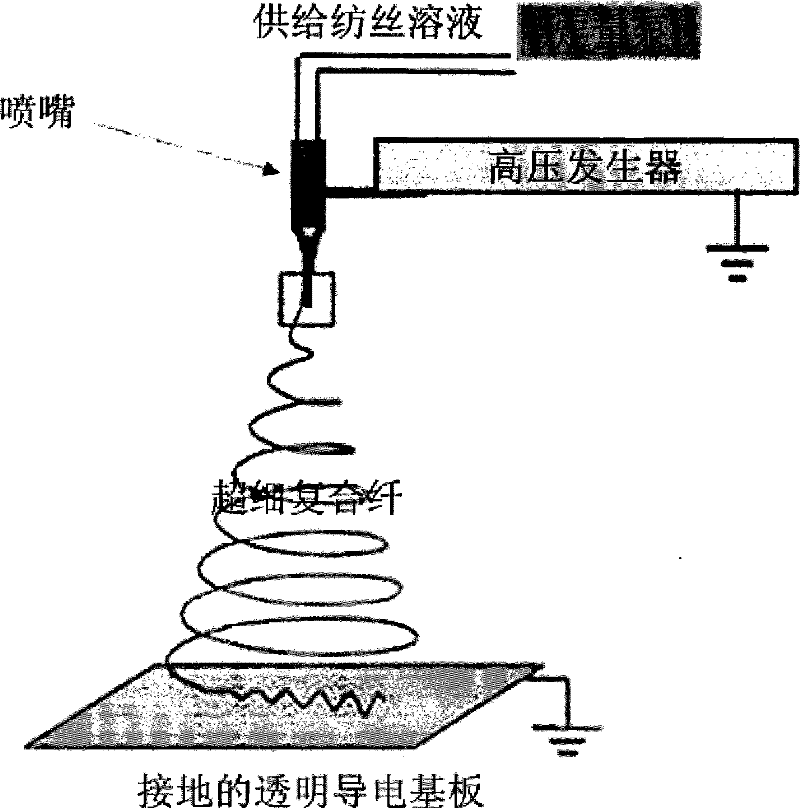

[0124] The electric spinning is used image 3 The electric spinning device shown uses the transparent conductive conductive base plate (10cm × 10cm size) of the FTO as the GROUNDED Receiver. The metal needle that is connected to the adjustable pump that can be adjusted as the pump is used as a positive pole.The voltage.Adjust the spitting speed of the spinning fluid to 10 μL / minute, 20 μL / minute, 30 μl / minute, 50 μl / minute, 100 μL / minute, and 200 μl / minute.PVAC / TIO on the transparent conductive substrate 2 Composite fiber layer.PVAC / TIO at different spitting speed 2 The average diameter of the fiber layer of the composite fiber layer is shown in Table 2 below.

[0125] 【Table 2】

[0126]

[0127] The above PVAC / TIO that will accumulate on the transparent conductive substrate through electric wires 2 The composite fiber layer was pressed at a pressure of about 1.5 tons at a pressure of about 10 minutes at 120 ° C. After 30 minutes of 500 ° C, the threshold titanium oxide ...

Embodiment 2

[0135] 【table 5】

[0136]

[0137] The light current density (JSC), voltage (VOC), filling factor (FF), and photoelectric conversion efficiency (η) with the substrate made of the titanium layer of the titanium oxide layer, see Table 6 below.

[0138] 【Table 6】

[0139] Embodiment

[0140] [Example 3]

Embodiment 3

[0142] [Example 4]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com