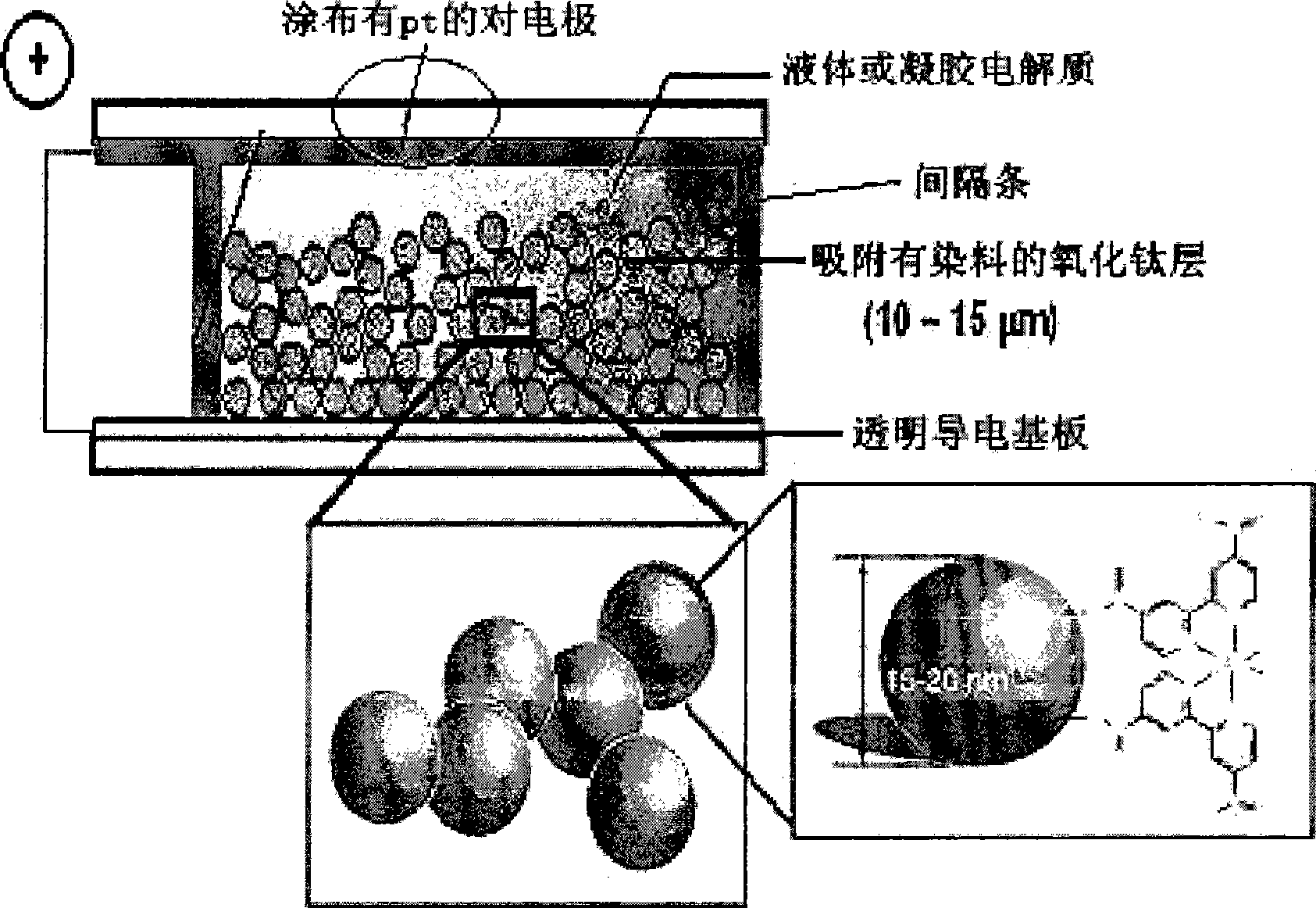

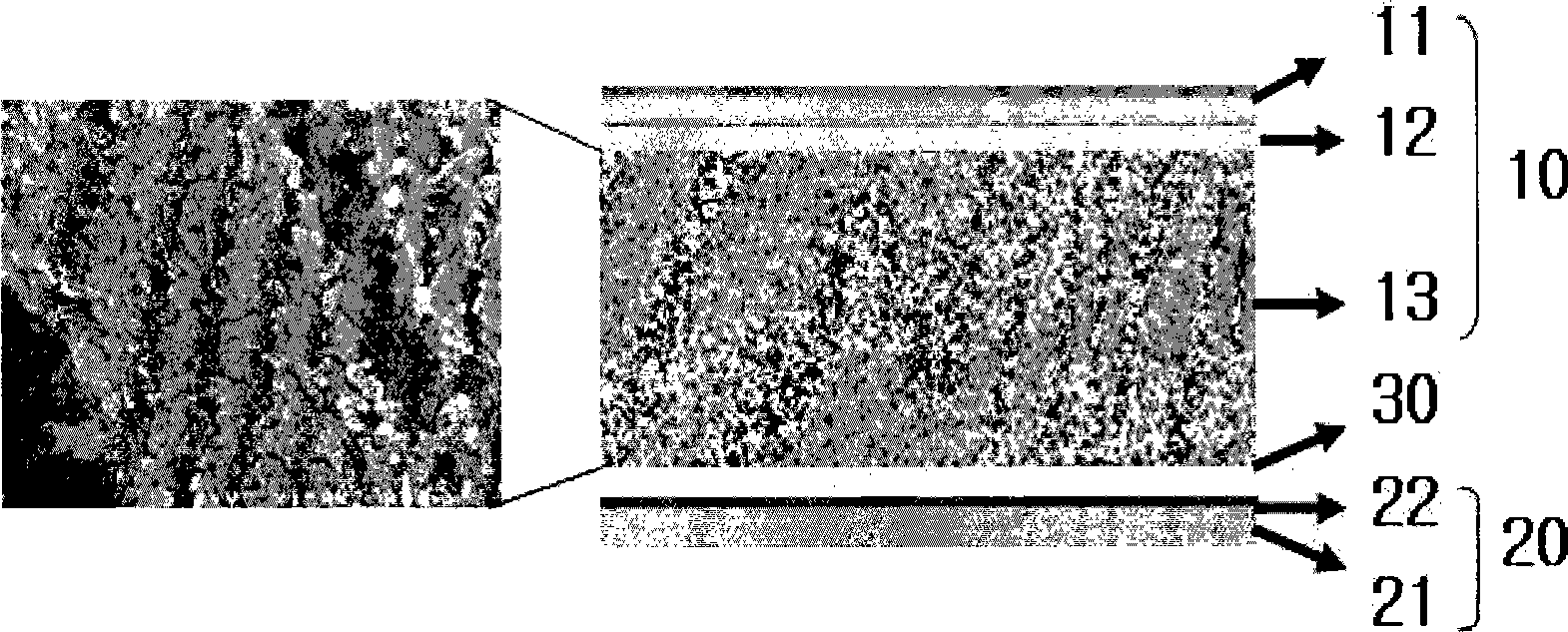

Dye-sensitized solar cell with metal oxide layer containing metal oxide nanoparticles produced by electrospinning and method for manufacturing same

A technology of solar cells and oxide layers, which is applied in the direction of secondary batteries, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as reduced charge transfer efficiency, irregular crystal planes, and reduced electron transfer capabilities, and achieve improved Effect of high photoelectric conversion efficiency and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

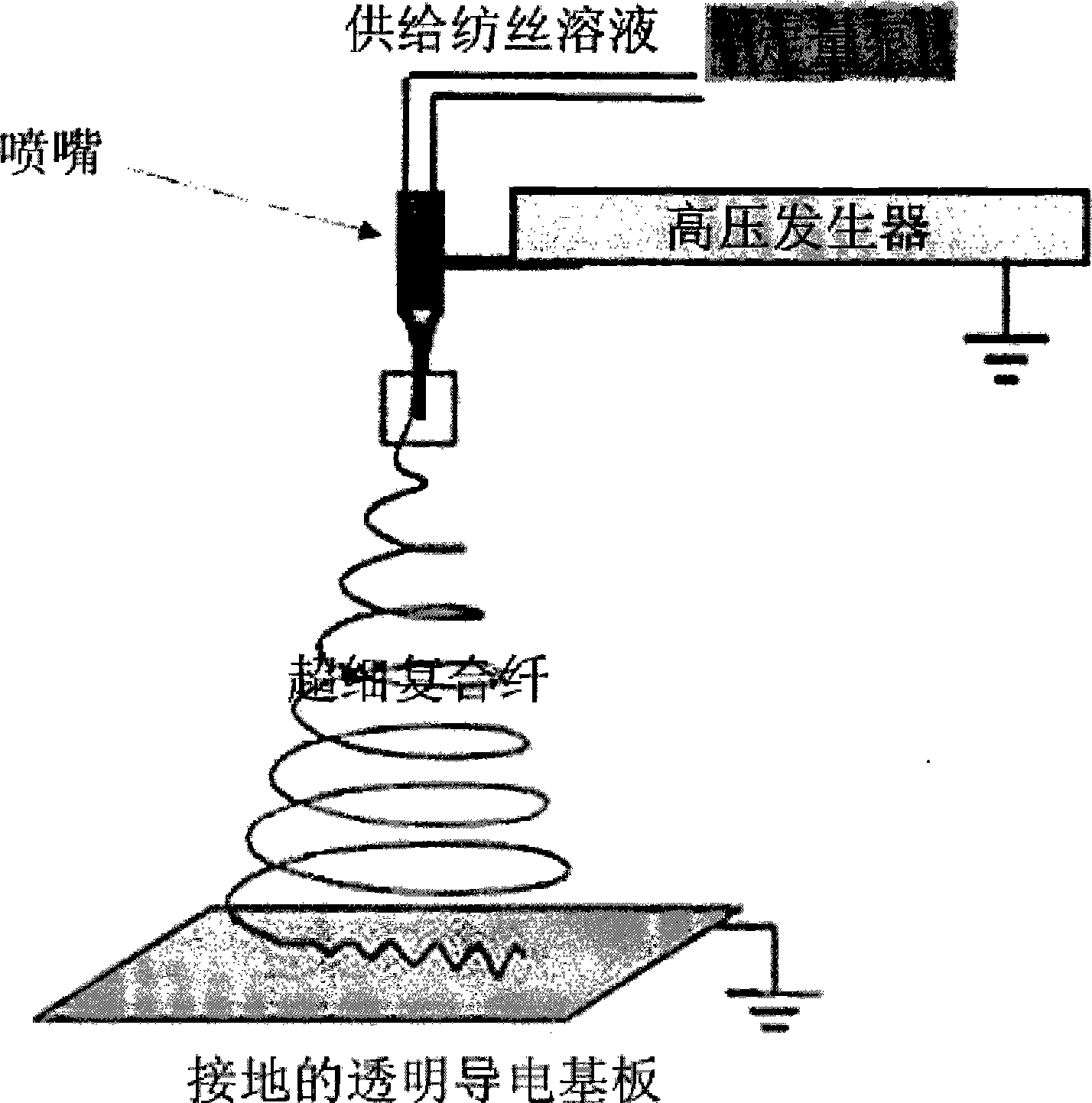

[0123] At room temperature, 60 g of isopropyl titanate was slowly added to a polymer solution prepared by dissolving 20 g of polyvinyl acetate (PVAc, Mw500,000, product of Aldrich Company) in 350 ml of dimethylformamide. At this point, the reaction starts and becomes a suspension due to the moisture in the solvent. Next, 24 g of acetic acid was slowly added dropwise as a reaction catalyst. At this point, the suspension turned into a clear solution as the reaction progressed. The prepared spinning solution was electrospun into titanium oxide fibers within 24 hours after preparation.

[0124] Electrospinning utilizes the image 3 In the electrospinning device shown, a transparent conductive substrate (10cm×10cm) coated with FTO is used as a grounded receiver, a metal needle connected to a pump with adjustable discharge speed is used as a positive electrode, and 15KV is connected between the two electrodes voltage. Adjust the discharge speed of the spinning solution to 10 μl / ...

Embodiment 2

[0134] With 20g polyvinyl acetate (PVAc, Mw 500,000, Aldrich company product), 60g isopropyl titanate, 24g acetic acid, 350ml dimethylformamide, after making spinning solution according to the method identical with embodiment 1, with The spinning solution was electrospun onto a transparent conductive substrate (10cm×10cm size) coated with FTO at a discharge speed of 20 μl / min, and the total discharge volume reached 5000μl, 6000μl, 7000μl, 9000μl and 10000μl, respectively, to produce With different thickness PVAc / TiO 2 Composite fiber layer substrate. Then they were pressurized with a pressure of about 1.5 tons at 120°C for 10 minutes in the same manner as in Example 1 to adjust the final thickness to 14 μm, and then sintered at 500°C for 30 minutes to remove polymers while An anatase-type titanium oxide nanoparticle layer is formed. The porosity and dye adsorption capacity of their titanium oxide layers are shown in Table 5 below.

[0135] 【table 5】

[0136]

[0137] Th...

Embodiment 3

[0141] With 20g polyvinyl acetate (PVAc, Mw 500,000, Aldrich company product), 60g isopropyl titanate, 24g acetic acid, 350ml dimethylformamide, after making spinning solution according to the method identical with embodiment 1, with The spinning solution was electrospun onto an FTO-coated transparent conductive substrate (10 cm × 10 cm in size) at a discharge speed of 20 μl / min to form PVAc / TiO 2 Composite fiber layer. They were then sintered at 500°C for 30 minutes at 500°C after pressurizing them at 120°C with a pressure of about 1.5 tons in the same manner as in Example 1, thereby forming anatase-type titanium oxides with different thicknesses while removing macromolecules. nanoparticle layer. The porosity and dye adsorption capacity of their titanium oxide layers are shown in Table 7 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com