Running tread incision comprising blocking parts

A technology of sipes and tread patterns, which is applied to tire treads/tread patterns, vehicle parts, transportation and packaging, etc., can solve the problems of reduced stiffness of tread patterns and achieve the effect of maintaining effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

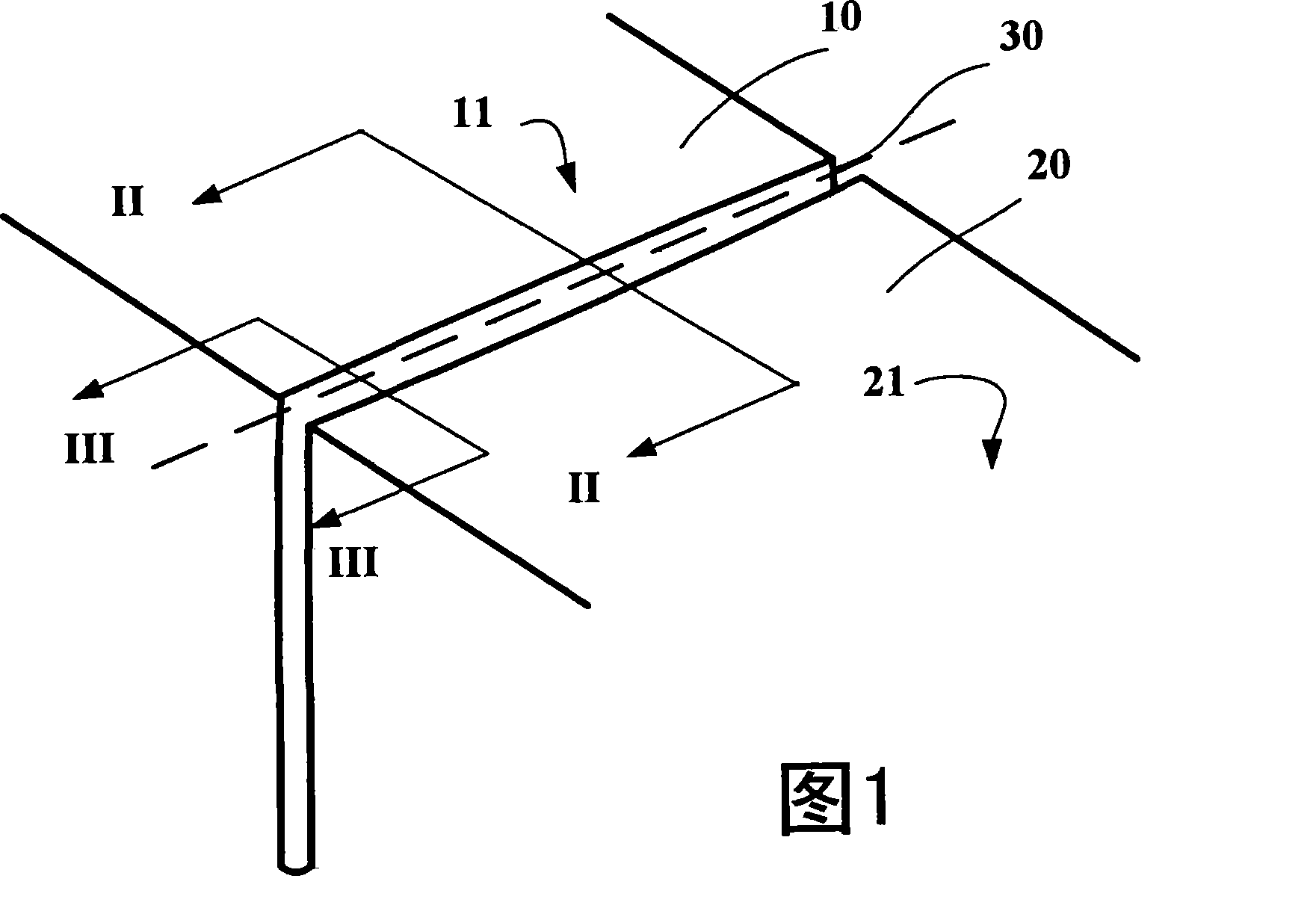

[0023] Figure 1 shows a partial view of a tire tread provided with a sipe according to the invention. In FIG. 1 , the two rubber components 10 , 20 of the tread pattern are separated from each other by a sipe 30 having an average width greater than 1.0 mm. The two rubber components 10 , 20 of the tread pattern have outer surfaces 11 , 21 which come into contact with the road surface during running, these surfaces 11 , 21 forming part of the tread surface of the tread.

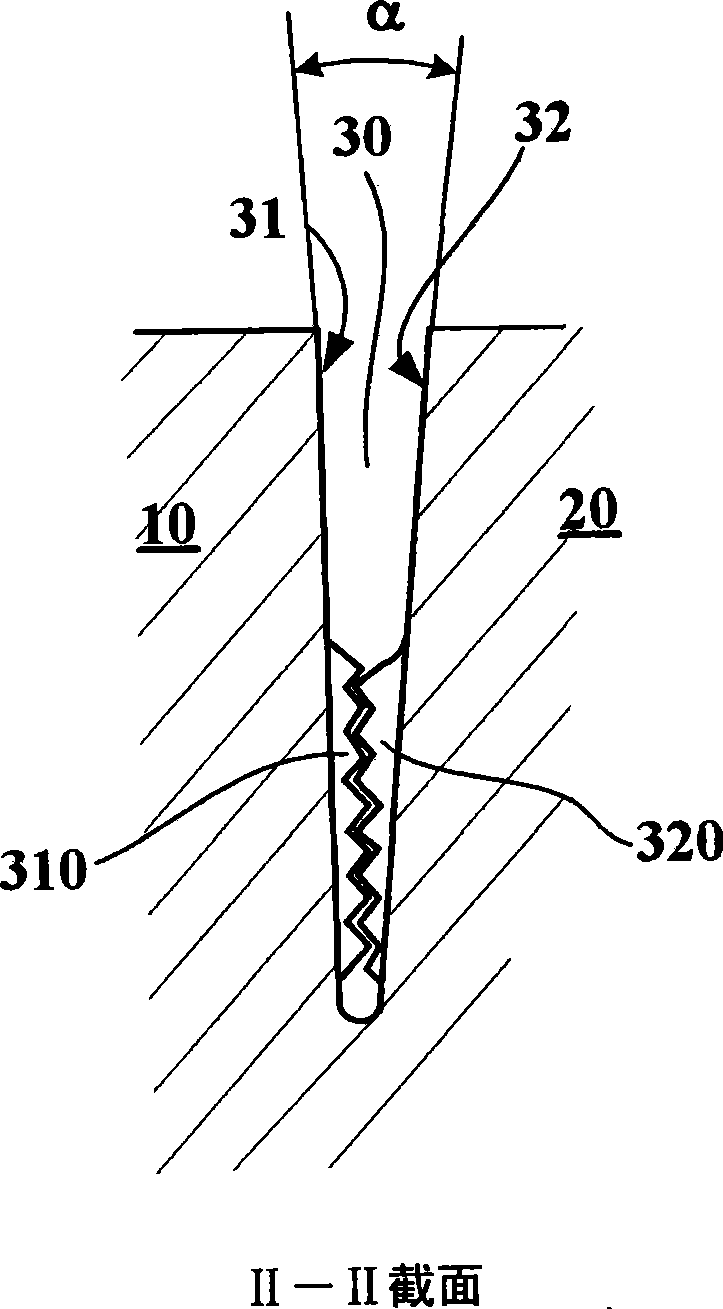

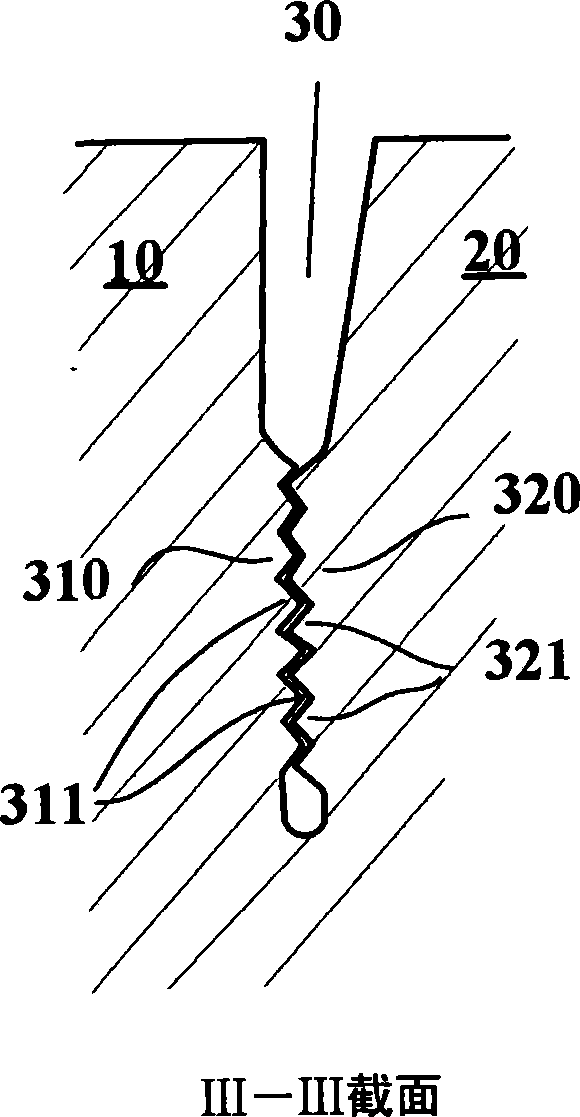

[0024] figure 2 and 3 Sectional views of the tread are shown along section planes II-II and III-III, perpendicular to the tread surface and identified in FIG. 1 .

[0025] figure 2 The edges of the main walls 31 , 32 of the sipe 30 in the section plane are shown, said walls 31 , 32 forming an angle α of 5 degrees therebetween. The virtual intersection of these edges is in the thickness of the tread. In an alternative form of the illustrated embodiment, the width of the sipe is 1.6 mm across the tread surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com