Microelectronic device with heating electrodes

A technology of microelectronic devices and heating arrays, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limiting the possible accuracy of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

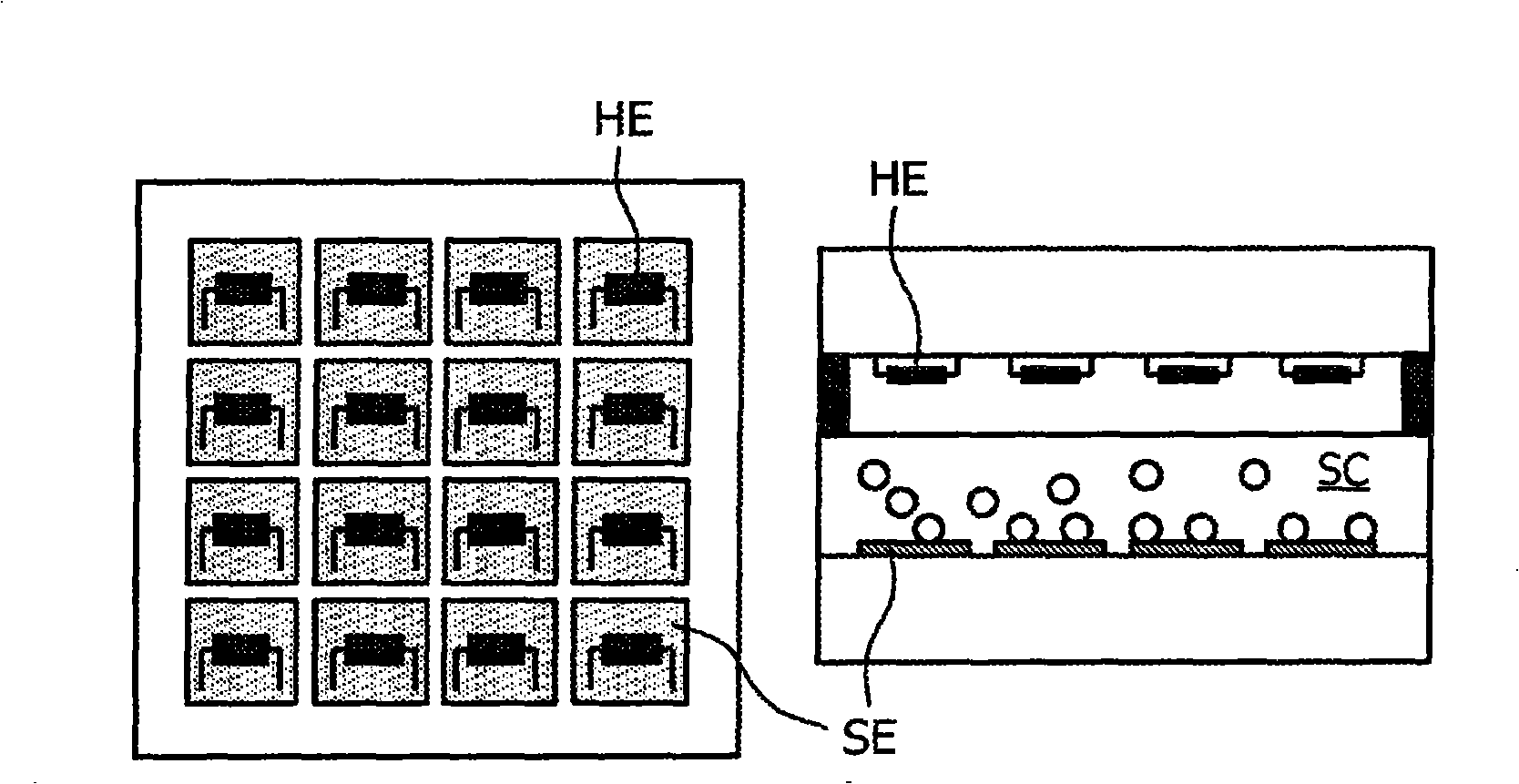

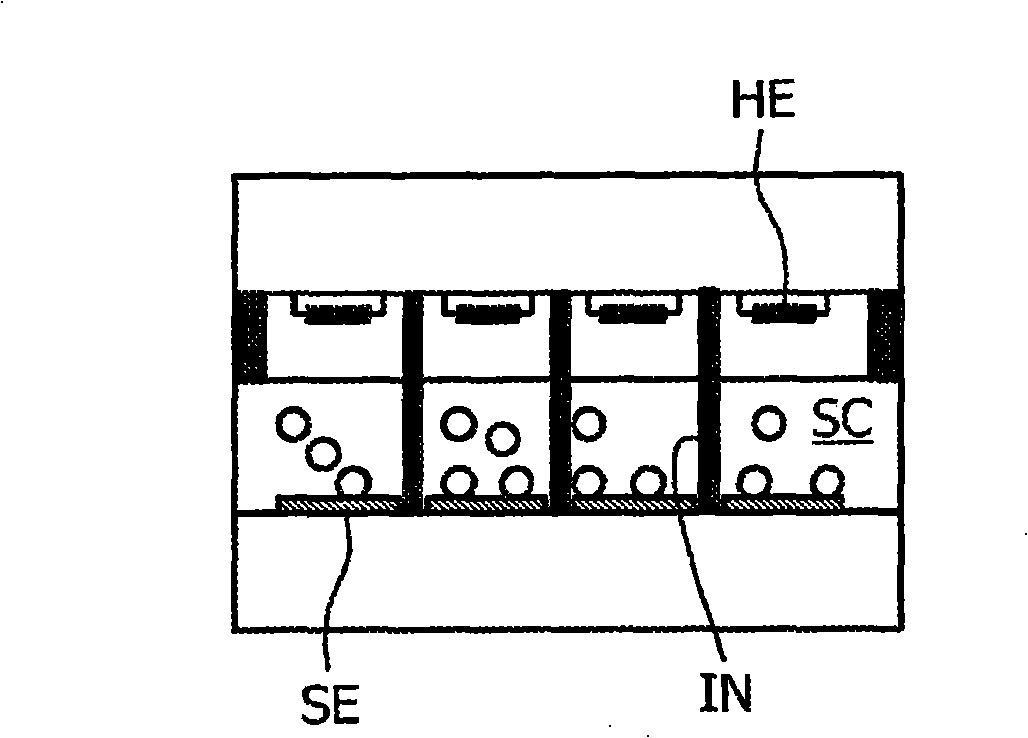

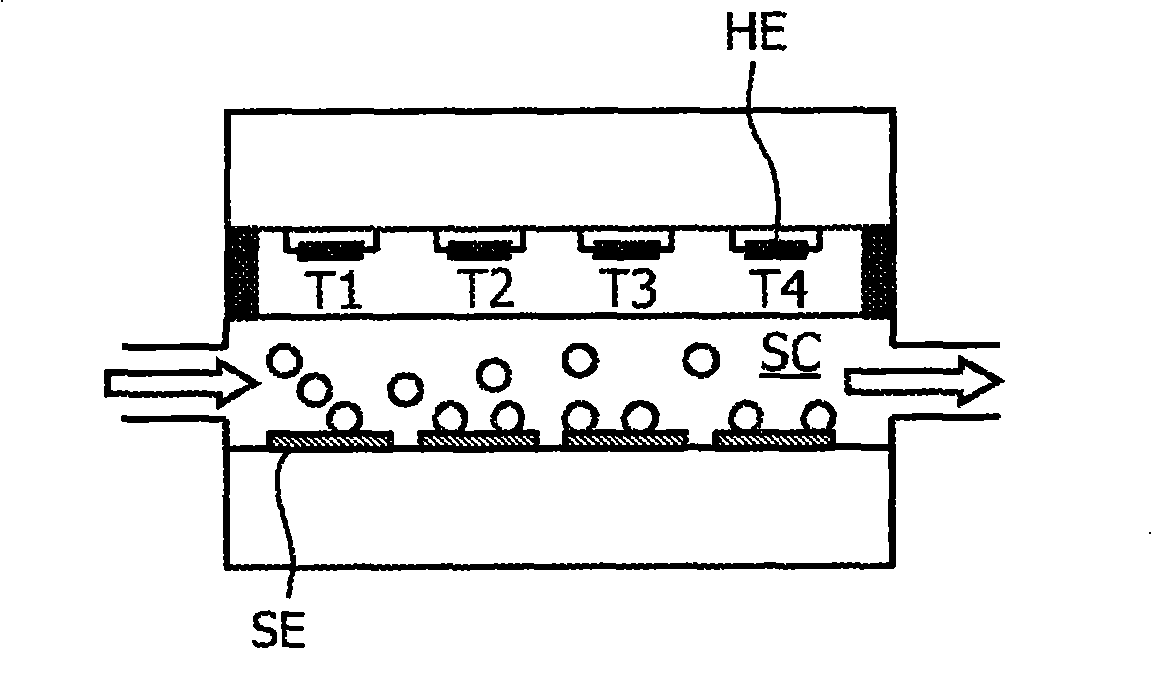

[0064] Biochips for (bio)chemical analysis, such as molecular diagnostics, will become an important tool for various medical, forensic and food applications. Typically, biochips include biosensors in which target molecules (e.g. proteins, DNA) are immobilized on biochemical surfaces with capture molecules and are subsequently detected using, for example, optical, magnetic or electrical detection schemes. The target molecule is detected. Examples of magnetic biochips are described in WO 2003 / 054566, WO2003 / 054523, WO 2005 / 010542 A2, WO 2005 / 010543 A1 and WO2005 / 038911 A1, which are hereby incorporated by reference into the present invention.

[0065] One way to improve the specificity of biosensors is to control the temperature, which is often used in hybridization assays to tune the tightness of binding of target biomolecules to functional surfaces, for example, the binding of a DNA strand to its complementary strand. A high degree of compactness is required when eg single po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap