LED light fitting

A technology of light-emitting diodes and lamps, which is applied to semiconductor devices, light sources, point light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

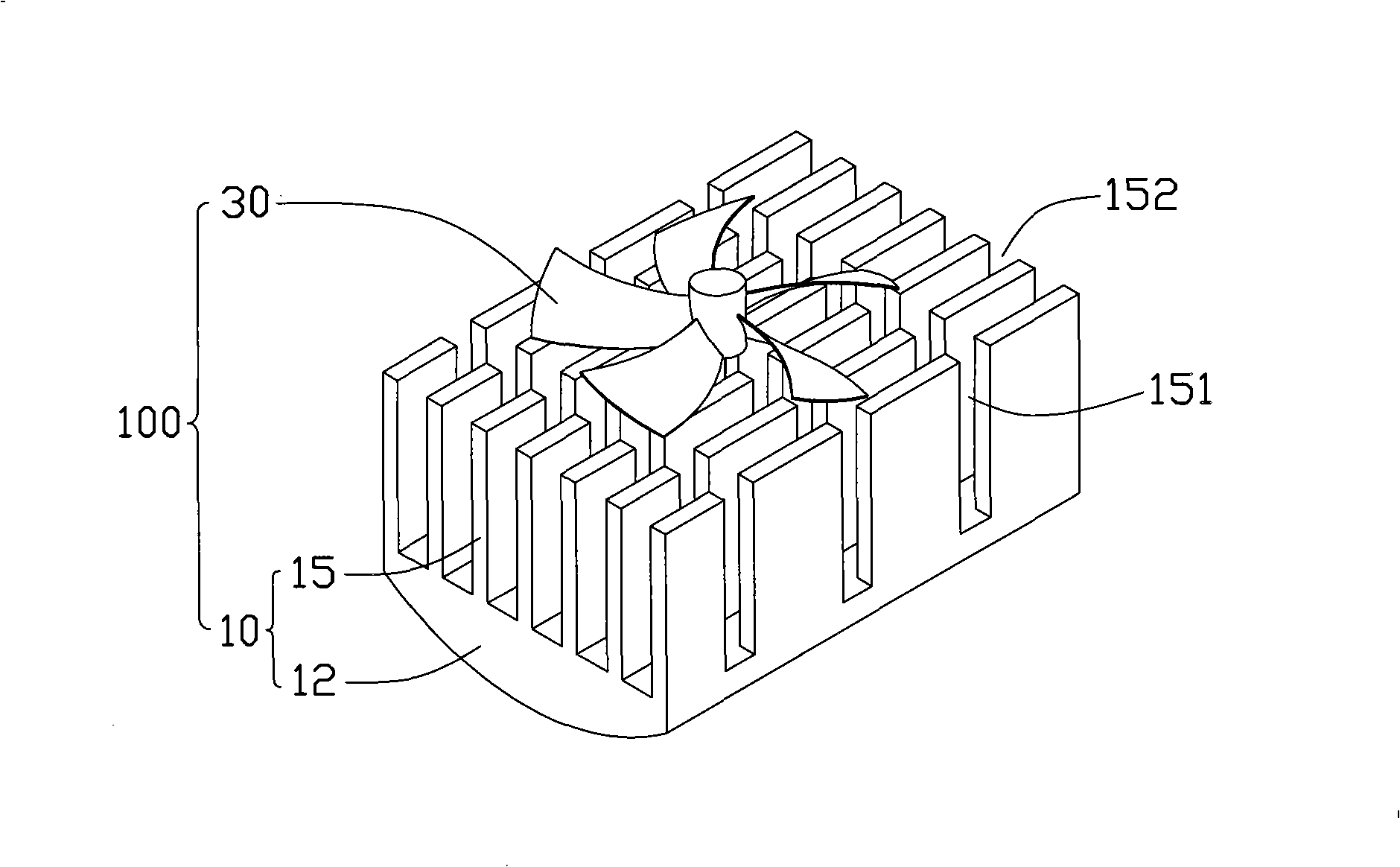

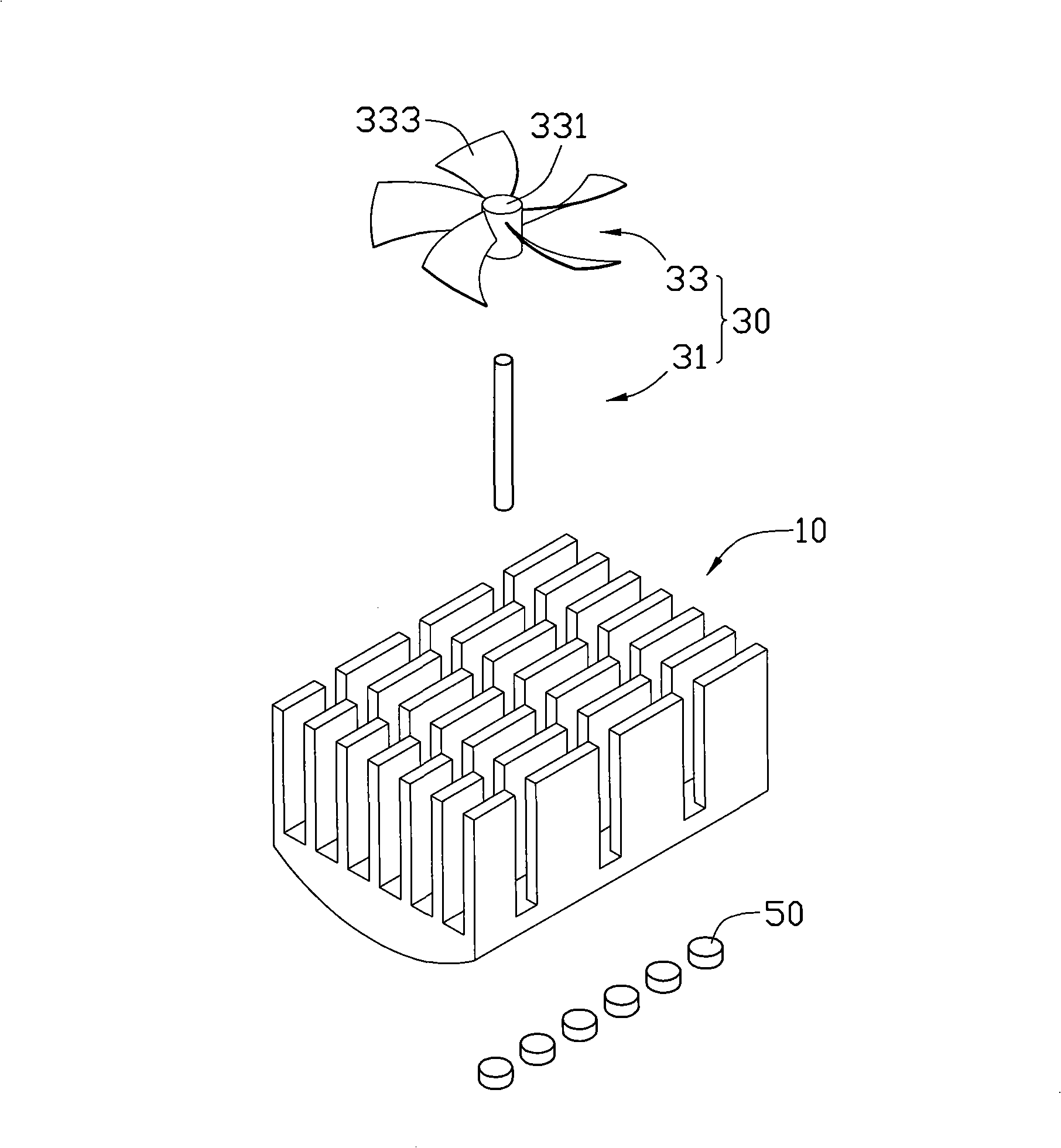

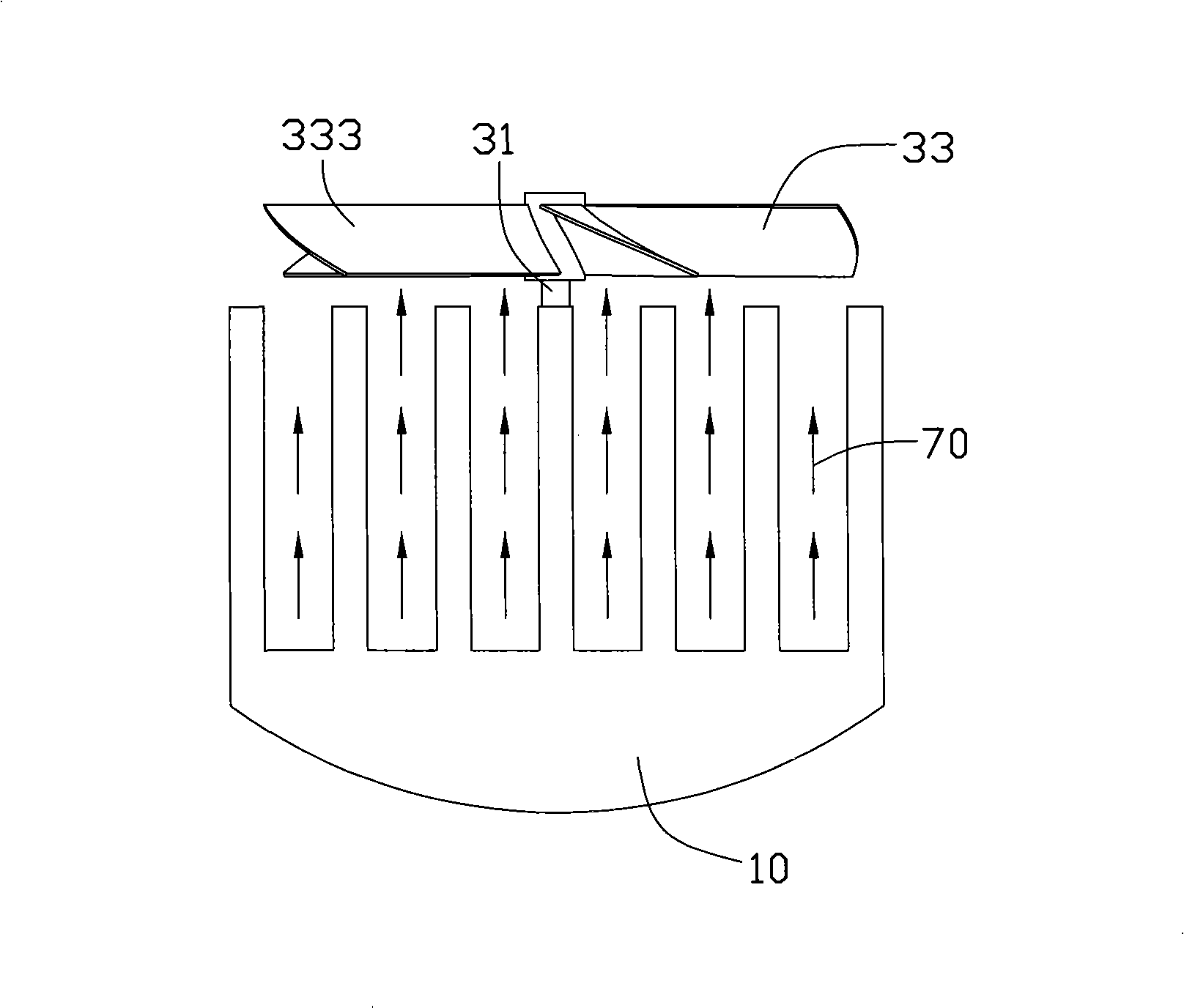

[0011] see figure 1 and figure 2 , is a heat dissipation device 100 according to an embodiment of the present invention. The heat dissipation device 100 includes a heat sink 10 and a temperature difference fan 30 arranged above the heat sink 10. The heat dissipation device 100 is used for heat dissipation in an LED lamp.

[0012] The heat sink 10 includes a base plate 12 and a plurality of heat dissipation fins 15 integrally extending upward from the top surface of the base plate 12 , and gaps 151 , 152 are spaced between the heat dissipation fins 15 horizontally and vertically. A plurality of LED modules 50 are mounted on the bottom of the substrate 12 . These LED modules 50 will generate a lot of heat during operation, and the heat will be conducted to the substrate 12 and the cooling fins 15 through contact with the substrate 12 .

[0013] The temperature difference fan 30 includes a support column 31 and an impeller 33 rotatably mounted on the support column 31. The impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com