Method and apparatus for keeping low pressure and vibration composite testing vibration table surface center

A technology of vibration center and compound test, which is applied in the direction of vibration test, measuring device, machine/structural component test, etc., can solve the problem that the compound test cannot be carried out normally, and achieve novel and ingenious design concept, highlighting substantive features, and remarkable technology progressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

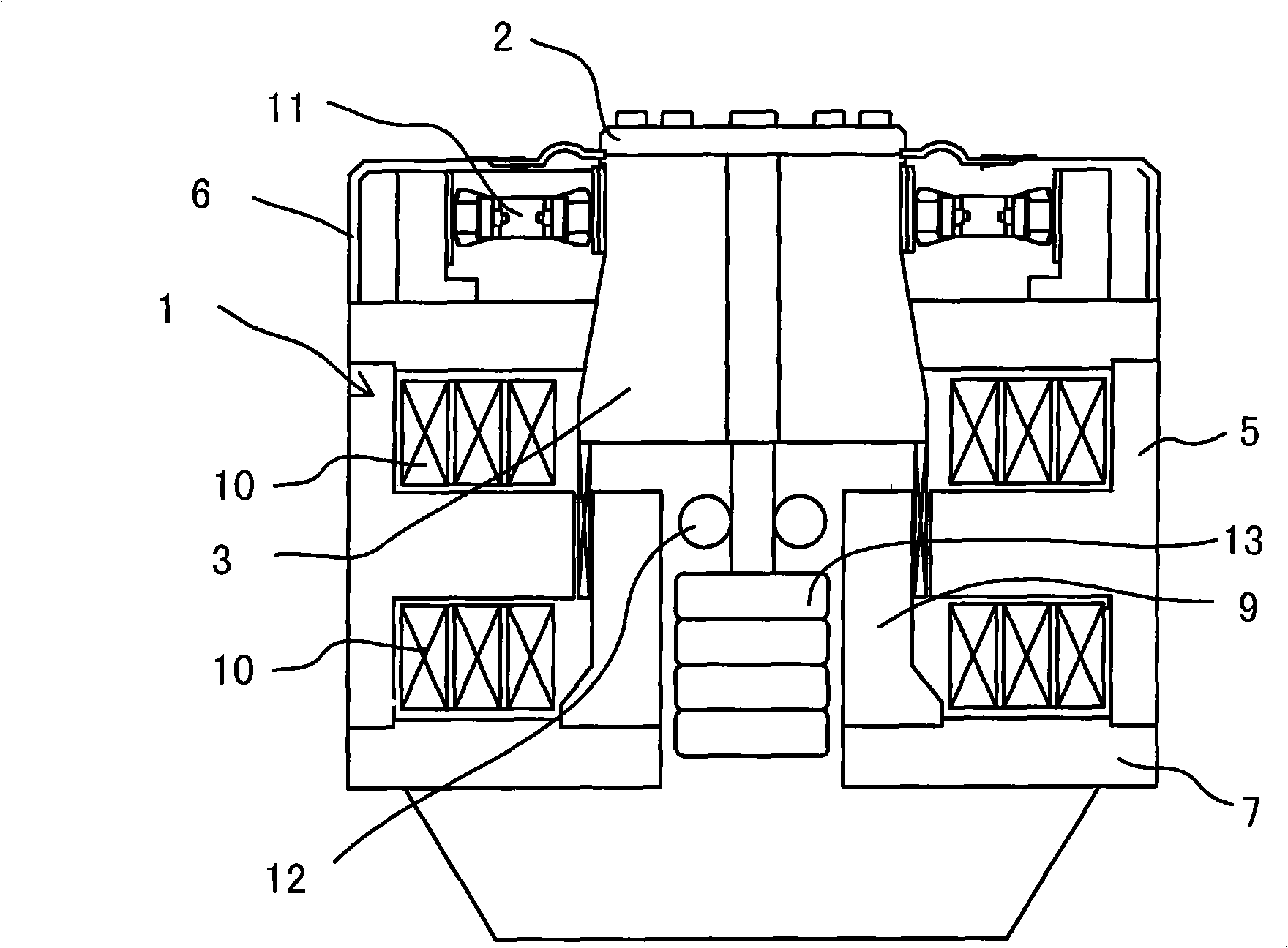

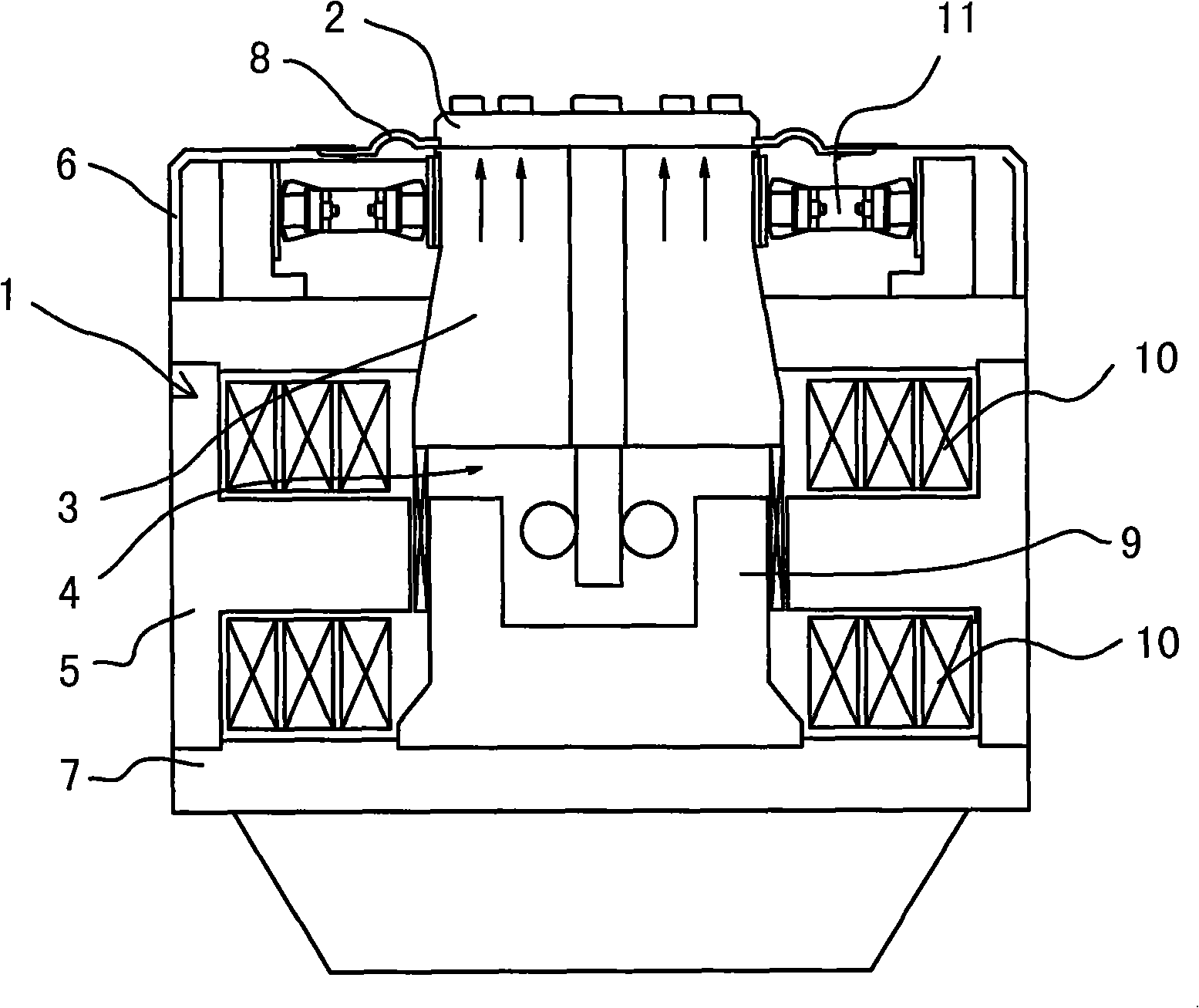

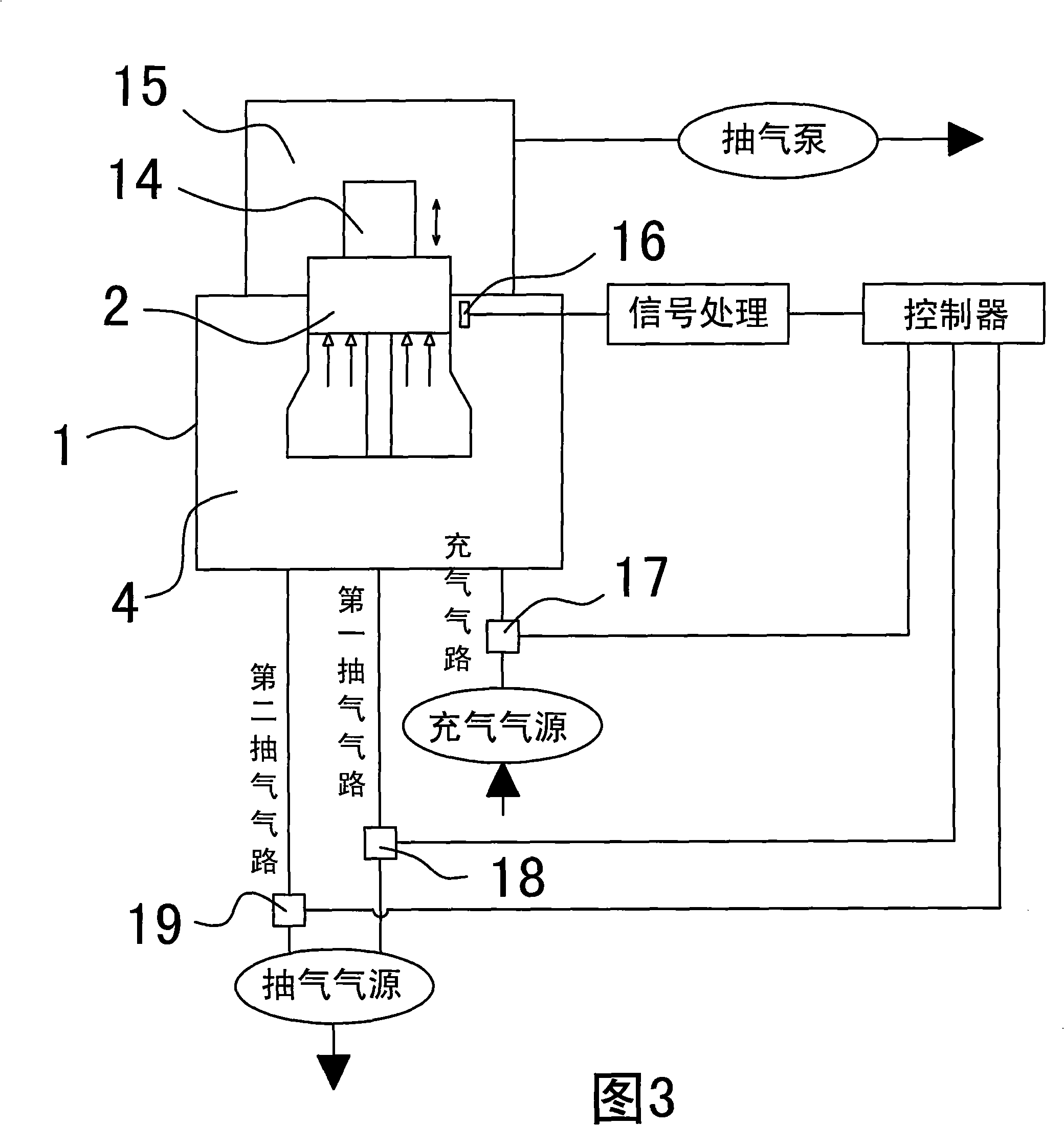

[0037] Example 1: A method and device for maintaining the center position of a vibrating table in a composite test of low air pressure and vertical vibration

[0038] Such as figure 2 As shown in Figure 3, the inner space of the electrodynamic vibrating table body 1 is designed as a sealed rigid air chamber 4, and the vibration center position of the table 2 and the test product 14 on the table 2 in the vertical vibration test is determined by the lower Air pressure test box 15 air pressure is supported by the floating balance of rigid air chamber 4 air pressure located below.

[0039] An inflation gas source (see FIG. 3 ) whose air pressure is always higher than the air pressure in the rigid air chamber 4 is set. The inflation air source can be understood as an air chamber full of pressurized air, and the air pressure in the air chamber is formed by inflating the air chamber by an air pump, and can also be understood as an air pump, and the outlet of the air pump forms a hi...

Embodiment 2

[0051] Example 2: A method and device for maintaining the center position of the vibrating table in a composite test of low air pressure and horizontal vibration

[0052] Such as Figure 5 As shown, the difference with Embodiment 1 is: the first point, the horizontal vibration test needs to increase the horizontal slide table 20, and the horizontal slide table 20 is composed of two parts, the slide table surface 21 and the pedestal 22, which are slidingly connected in the horizontal direction (for the existing with technology). The second point is to turn over the table body 1 of the electric vibration table by 90 degrees, then connect the table top 2 on the table body 1 of the electric vibration table to the slide table top 21 of the horizontal slide table 20, and use the electric vibration table to drive the slide table top 21 Conduct vibration tests in the horizontal direction. In the third point, the test product 14 is installed on the slide table top 21 of the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com