Hollow polymer particle, colored hollow polymer particle and their production methods

A polymer particle, hollow technology, used in transportation and packaging, thin material handling, etc., can solve problems such as complex operations, water droplet size disruption, particle size inconsistency, etc., to achieve the effect of inhibiting heat conduction, light weight and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of the present invention will be described in detail below.

[0078] The preparation method of the present invention is a method for preparing hollow polymer particles in a single tank, that is, without separation operation in the same reactor, and is characterized in that the free radical polymerizable The water-soluble monomer (A) and the radical-polymerizable water-insoluble monomer (B) are subjected to pseudo-emulsion radical polymerization.

[0079] As the aqueous medium used in the aforementioned pseudo-emulsion polymerization, in addition to using water alone, lower alcohols such as methanol, ethanol, isopropanol, ethylene glycol, propylene glycol, butylene glycol, diethylene glycol, triethylene glycol, etc. Polyols such as acetone and methyl ethyl ketone, ethers such as tetrahydrofuran alone or mixed in water.

[0080] When using a mixed solvent, as its mixing ratio, as long as the water-soluble polymerization initiator described later an...

Embodiment 1

[0108] [Synthesis of hollow polymer particles including poly(NIPAM-co-GMA), a copolymer of N-isopropylacrylamide (NIPAM) and glycidyl methacrylate (GMA)]

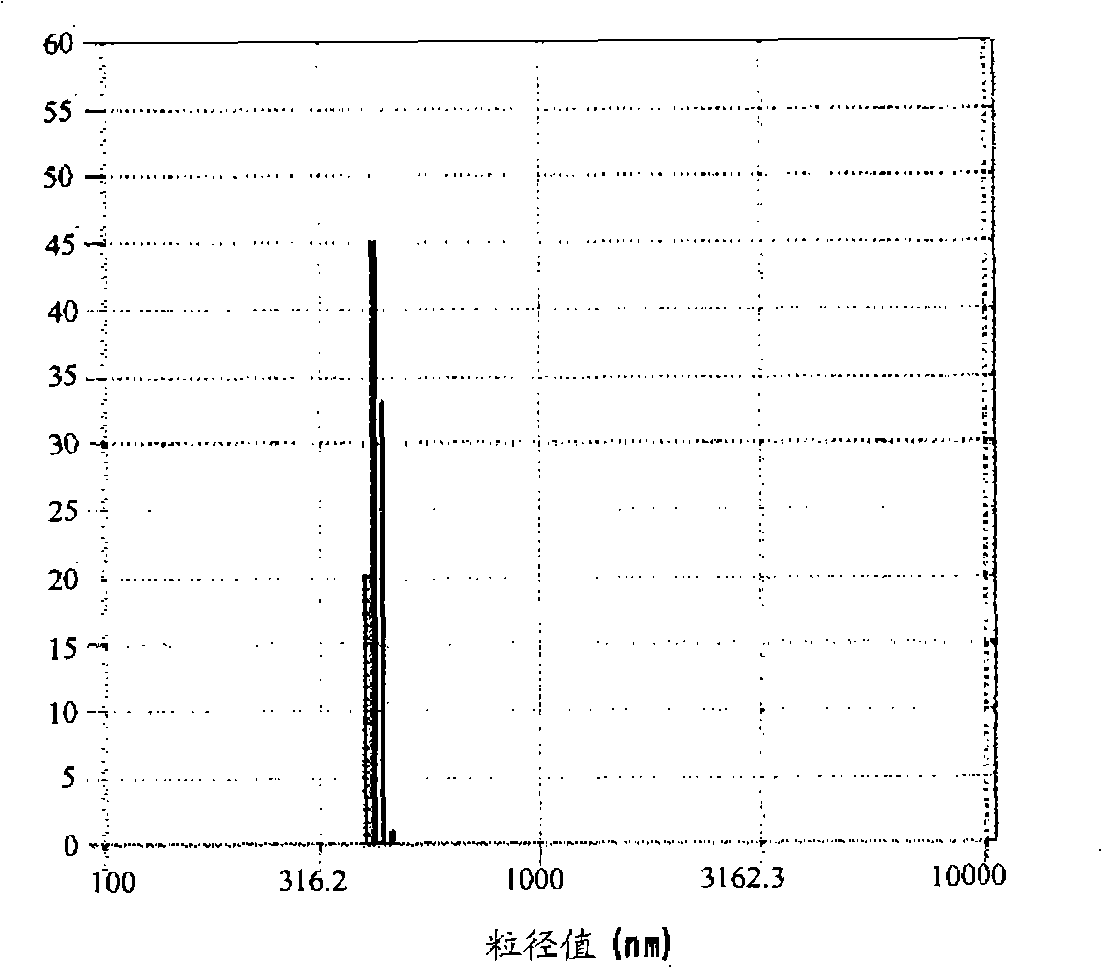

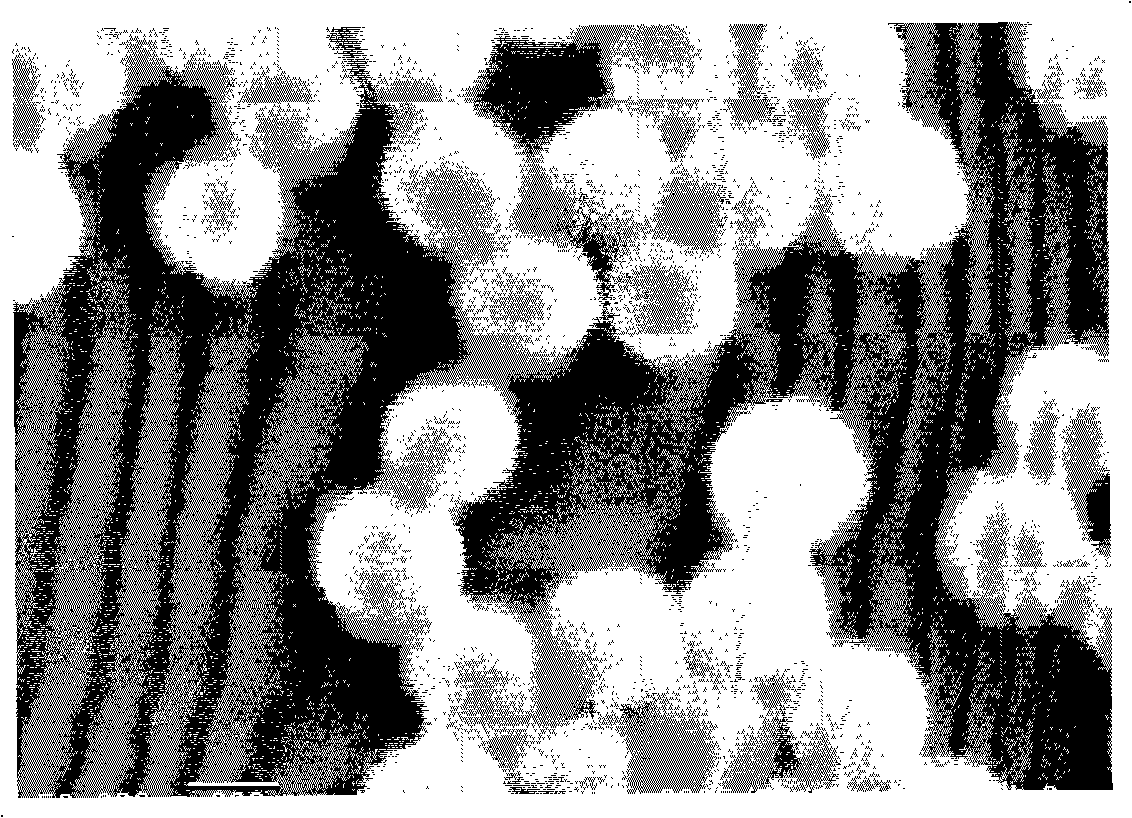

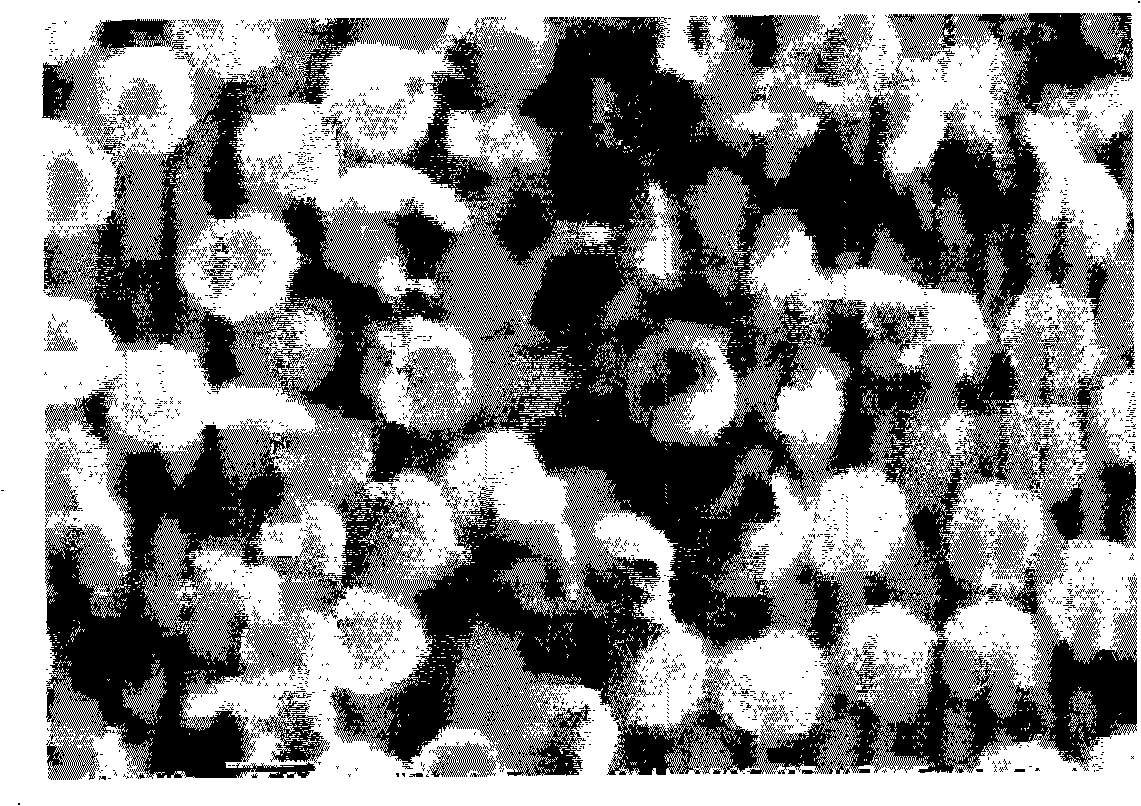

[0109] Add 8.52 g of glycidyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd., hereinafter referred to as NIPAM) in 200 ml of an aqueous solution in which 1.4 g of N-isopropylacrylamide (manufactured by Xingren Co., Ltd., hereinafter referred to as NIPAM) was dissolved. GMA), heated to 70 °C while stirring under nitrogen atmosphere. 20 ml of an aqueous solution in which 0.1 g of a water-soluble polymerization initiator potassium persulfate (KPS, manufactured by Wako Pure Chemical Industries, Ltd.) was dissolved was added to this mixture (GMA / NIPAM=4.8 mol / mol). A dispersion of particles was obtained by stirring at this temperature for 1 hour. The dispersion was washed and purified by centrifugation. Through dynamic light scattering, SEM and 1 Identification of the purified particles was performed by H-N...

Embodiment 2~26

[0111] [Synthesis of hollow polymer particles including copolymers of various water-soluble monomers and water-insoluble monomers]

[0112] Except that the amount of the water-soluble monomer (A) used in Example 1, the water-insoluble monomer (B), the water-soluble polymerization initiator and the aqueous solution are changed to each value in Table 1, obtain in the same way as Example 1 Hollow polymer particles. The property values of the obtained granules are summarized in Table 2. In addition, Example 6 is an example using sodium lauryl sulfate as a surfactant, and it was used after adding a predetermined amount to an aqueous solution of NIPAM and stirring it uniformly.

[0113] [Table 1]

[0114] Table 1 embodiment feed list

[0115]

[0116] Table 1 Note:

[0117] MBAM: N,N'-Methylenebisacrylamide

[0118] DMAA: N,N-dimethylacrylamide

[0119] ACMO: Acryloylmorpholine

[0120] AA: Acrylic

[0121] MAP-TMACl: 3-(methacrylamido)propyltrimethylammonium chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com