Optical objective module

An optical module and optical lens technology, applied in optics, optical components, installation, etc., can solve the problems of reduced image quality and reduced focusing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

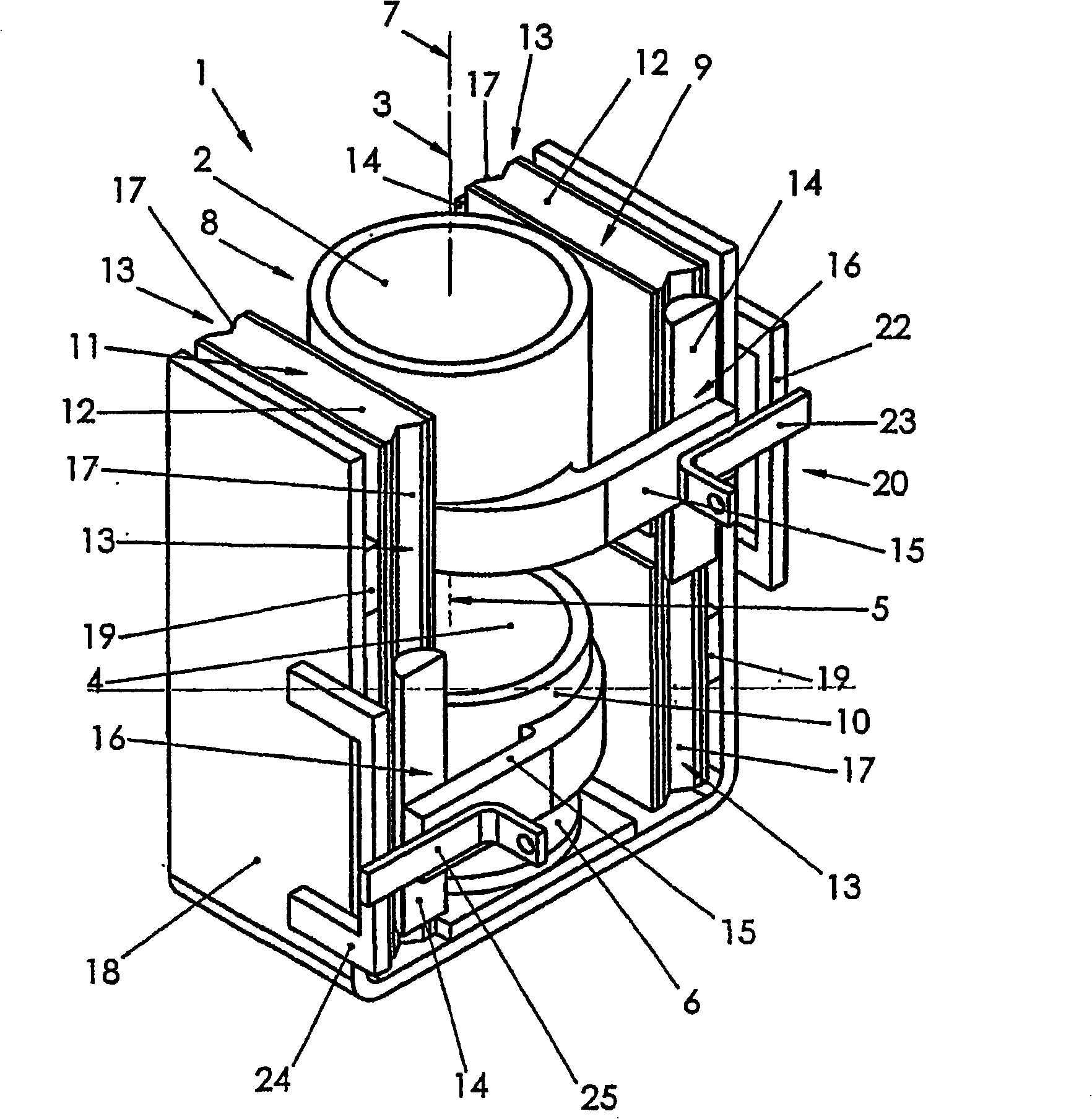

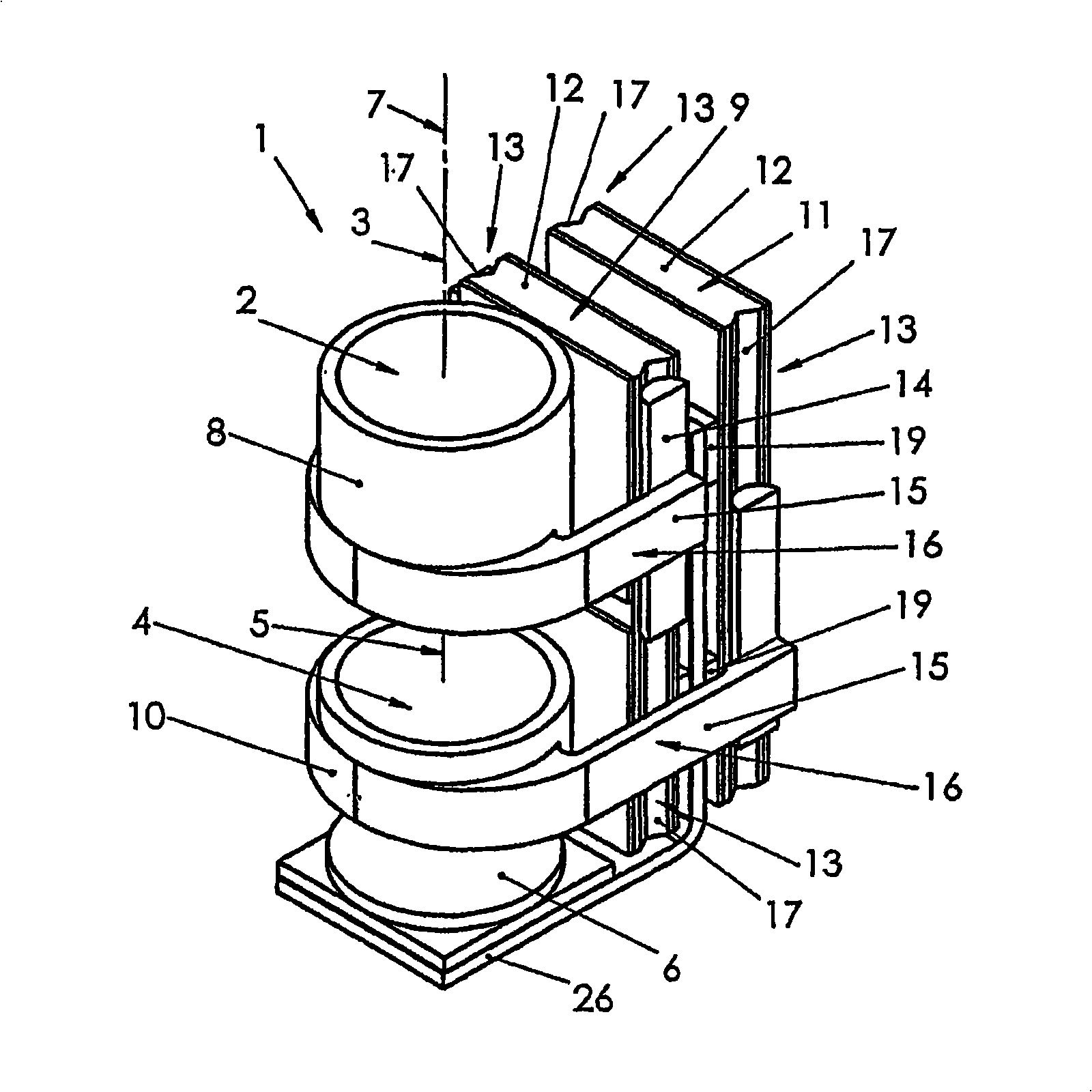

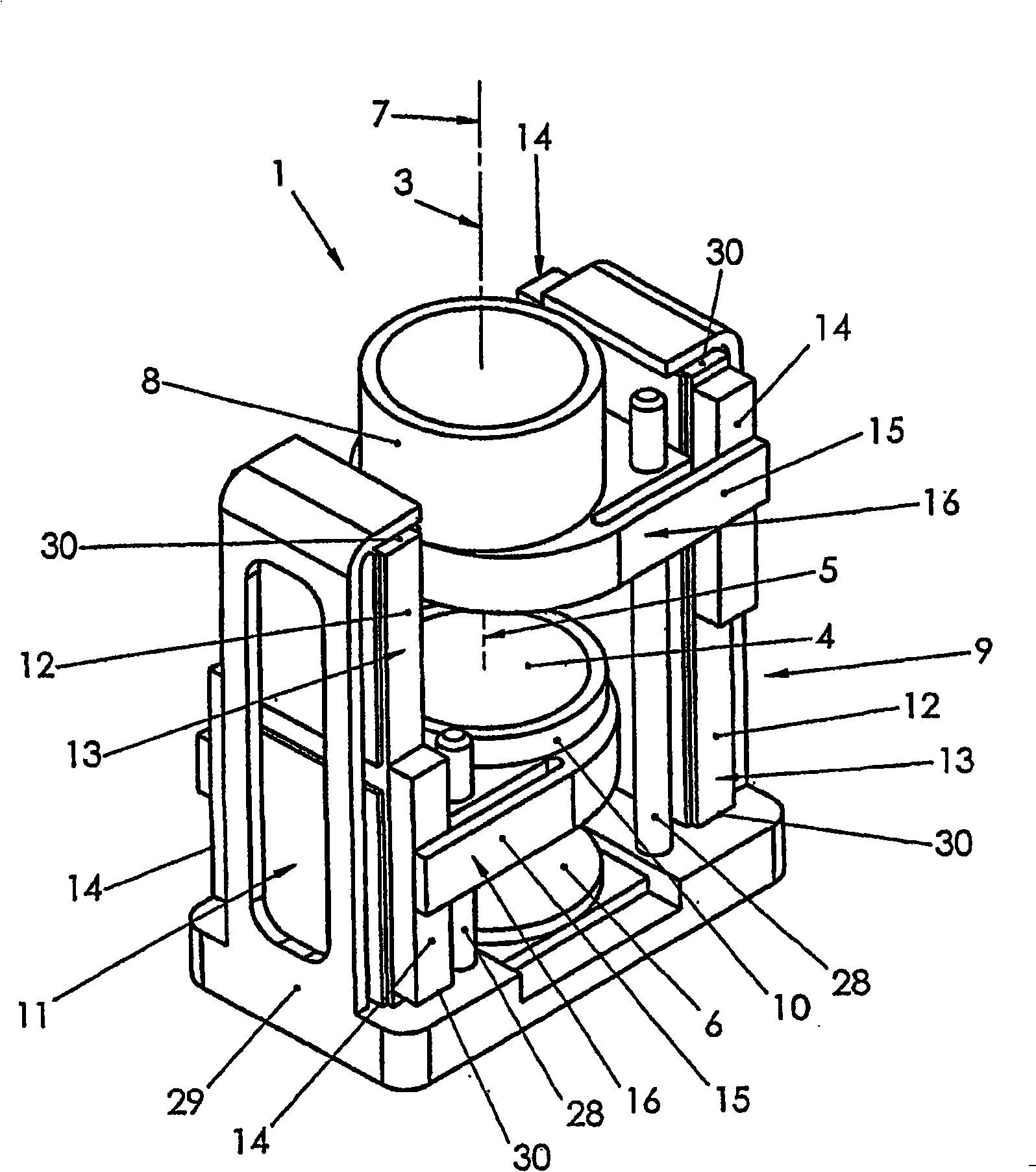

[0052] Optical Micromodule 1( figure 1 ) includes a zoom lens group 2 with an optical axis 3, a focusing optical lens group 4 with an optical axis 5, and a photoelectric imaging sensor 6. The two optical lens groups 2 , 4 are arranged such that their optical axes 3 and 5 coincide and together form the optical axis 7 of the optical module 1 .

[0053]The optical lens group 2 is mechanically connected to the first ultrasonic motor 9 by a mount 8 . The optical lens group 4 is mechanically connected to the second ultrasonic motor 11 by the carrier 10 .

[0054] The two ultrasonic motors 9 , 11 together form the drive of the optical module 1 .

[0055] The two ultrasonic motors 9 and 11 consist of a piezoelectric plate 12 with friction elements 14 which press against opposing side surfaces 13 . An elastic press-on element 15 pressing the friction element 14 against the side surface 13 forms part of the carrier 8 , 10 . The friction element 14 together with the pressing element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com