An Optical Sensing System Based on CMOS Processing Technology

A processing technology and optical sensing technology, applied in the field of optical sensing and optical communication, to achieve the effect of extended function application and simple process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

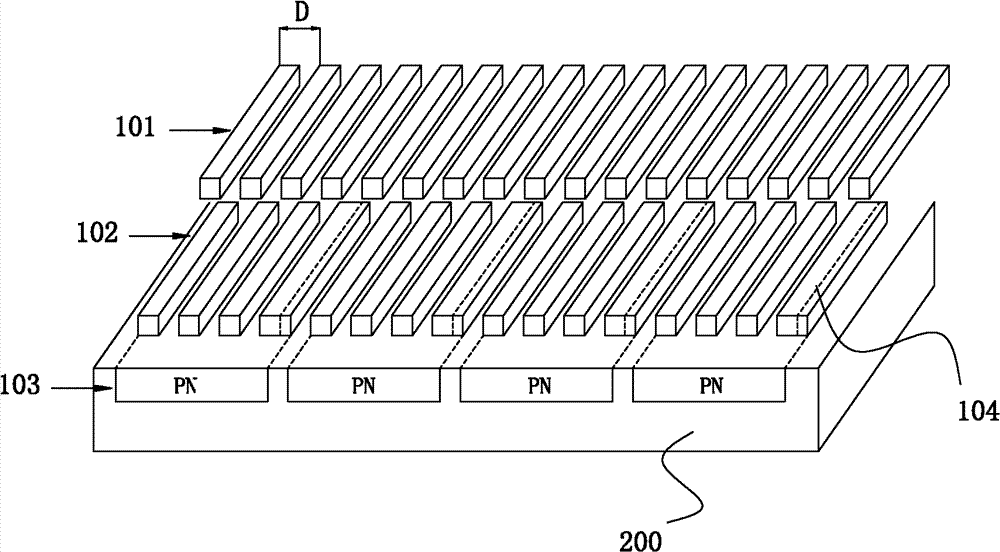

[0021] attached image 3 A schematic diagram of the structure of the sensing unit based on the CMOS process in Embodiment 1 is shown. The sensing unit 100 is composed of a diffraction grating 101, an analysis grating 102 and a PN junction array 103. The diffraction grating 101 and the analysis grating 102 are arranged in a double-layer parallel structure on the CMOS In the metal wiring layer of the circuit board, the analysis grating 102 is arranged in parallel below the diffraction grating 101, and the parallel distance between the analysis grating 102 and the diffraction grating 101 is 1 / 2 times the Tebao distance of the diffraction grating, and four PN junctions form a PN junction The array 103 is located below the analysis grating 102 and is arranged in the silicon substrate layer 200 of the CMOS circuit board. Corresponding to each PN junction, the width of a blocking grating 104 is increased by 1 / 4D in the analysis grating 102 at equal intervals, and D is diffraction The...

Embodiment 2

[0033] attached Figure 4A schematic diagram of the structure of the sensing unit based on the CMOS process in Embodiment 2 is shown. The sensing unit 100 is composed of a diffraction grating 101, an analysis grating 102 and a PN junction array 103, and the diffraction grating 101 and the analysis grating 102 are arranged in a double-layer parallel structure In the metal wiring layer of the CMOS circuit board, the analysis grating 102 is arranged in parallel below the diffraction grating 101, the parallel distance between the analysis grating 102 and the diffraction grating 101 is the diffraction grating Taibao distance, and four PN junctions form a PN junction array 103 Located below the analysis grating 102 and arranged in the silicon substrate layer 200 of the CMOS circuit board, corresponding to each PN junction, the width of a grating gap 105 in the analysis grating 102 is increased by 1 / 4D at equal intervals, and D is the diffraction grating 101 The grating pitch is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com