Transmission method of electric motor of coiling machine

A technology for a coiler and a machine motor, which is applied in the field of metallurgical equipment, can solve the problems of increased energy consumption of the motor, increased rotational inertia of the motor rotor, complicated reduction box of the coiler, etc., and achieves the effect of improving plate shape and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

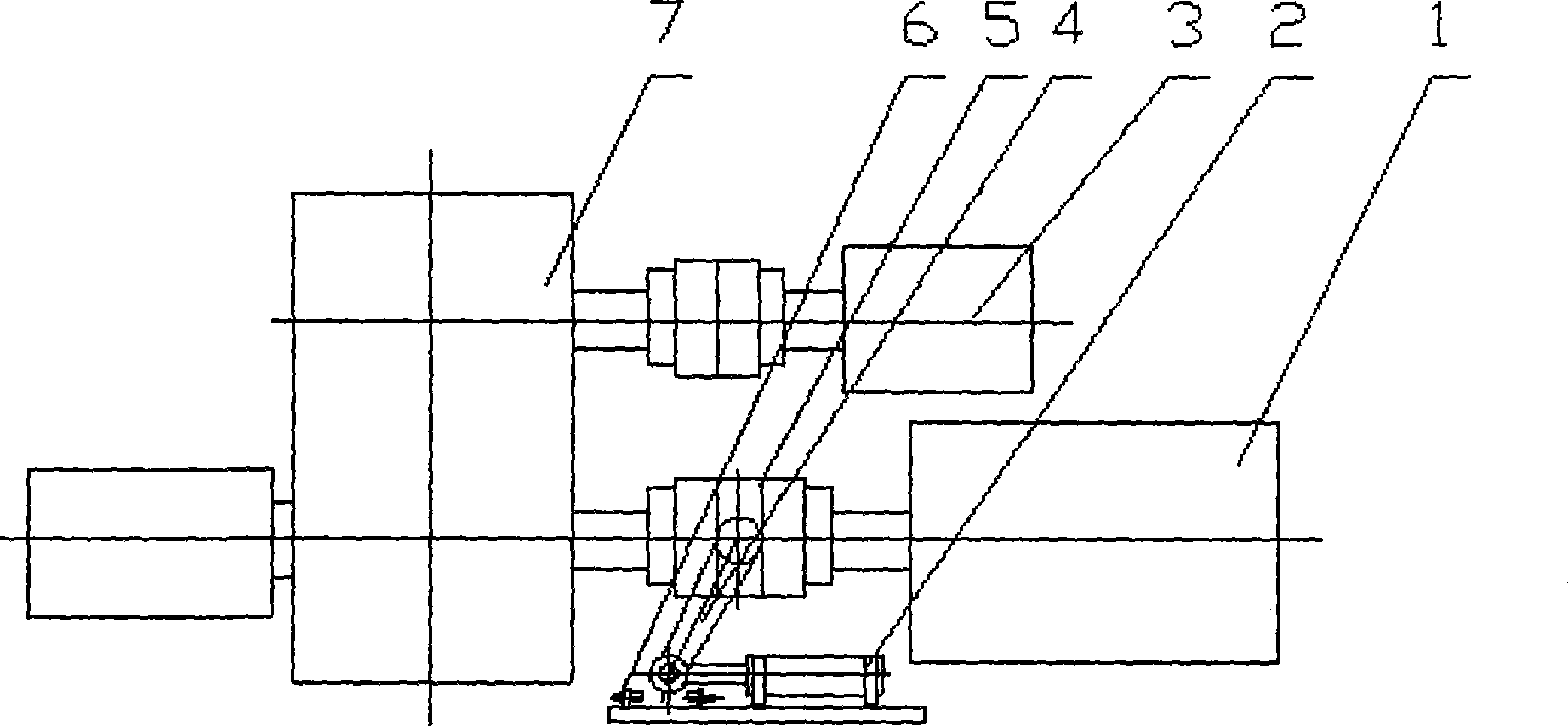

[0010] Such as figure 1 As shown: the coiler body 7 is connected with a large motor 1 and a small motor 3, and the large motor 1 and the coiler body 7 are connected through a detachable coupling 5, which can be detached from the fork cylinder 2 connection; when a large tension is used, the shift fork cylinder 2 stretches out, and the shift fork 4 connected to it pushes the disengageable coupling 5 to connect the large motor 1 with the coiler body 7. At this time, the large and small motors Work at the same time; when the small tension is used, the shift fork cylinder 2 retracts, and the shift fork 4 connected to it pushes the disengageable coupling 5 to disengage the large motor 1 from the coiler body 7. At this time, the large motor 1 No work, only the small motor 3 drives the coiler body 7 to work; the extension and retraction positions of the fork cylinder 2 are detected by the proximity switch 6, and the signal is sent to the electrical system to realize interlocking contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com