Rotary switch type drawdown casting device

A technology of rotary switch and heating device, applied in foundry equipment, foundry workshop, metal processing equipment, etc., can solve the problems of unsatisfactory fluid flow controllability and safety, inability to effectively control fluid flow, low operational flexibility, etc. Significant economic and social effects, small footprint, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

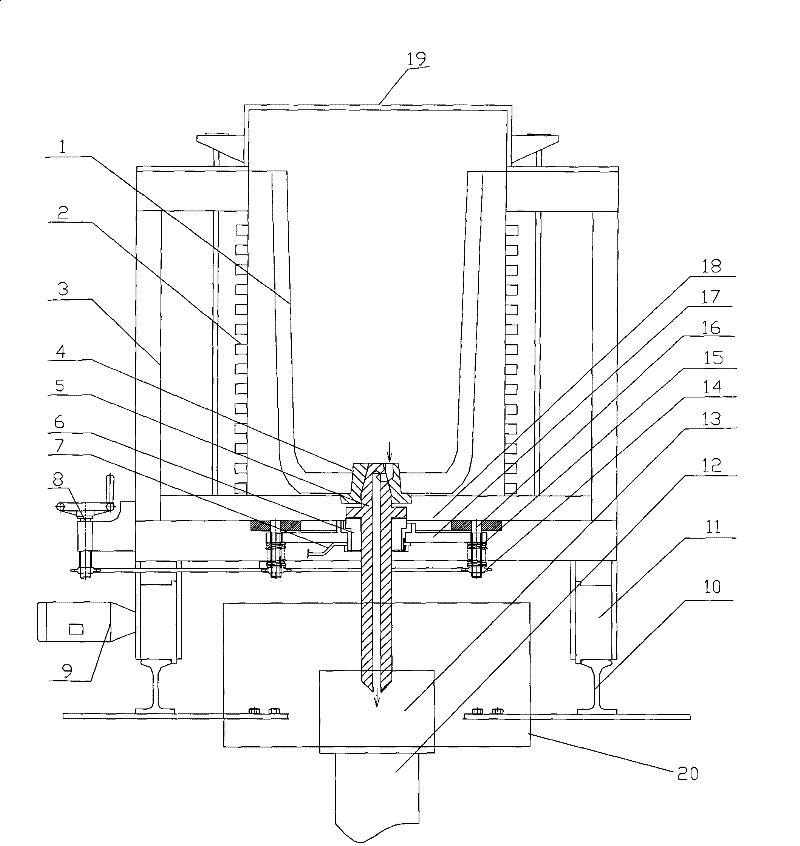

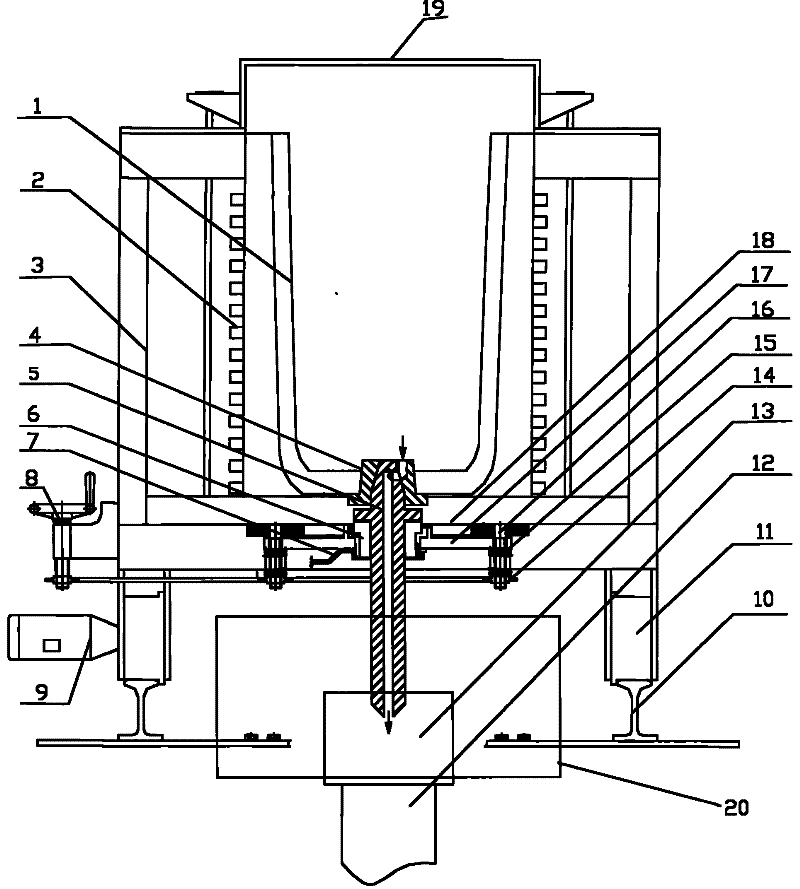

Image

Examples

Embodiment

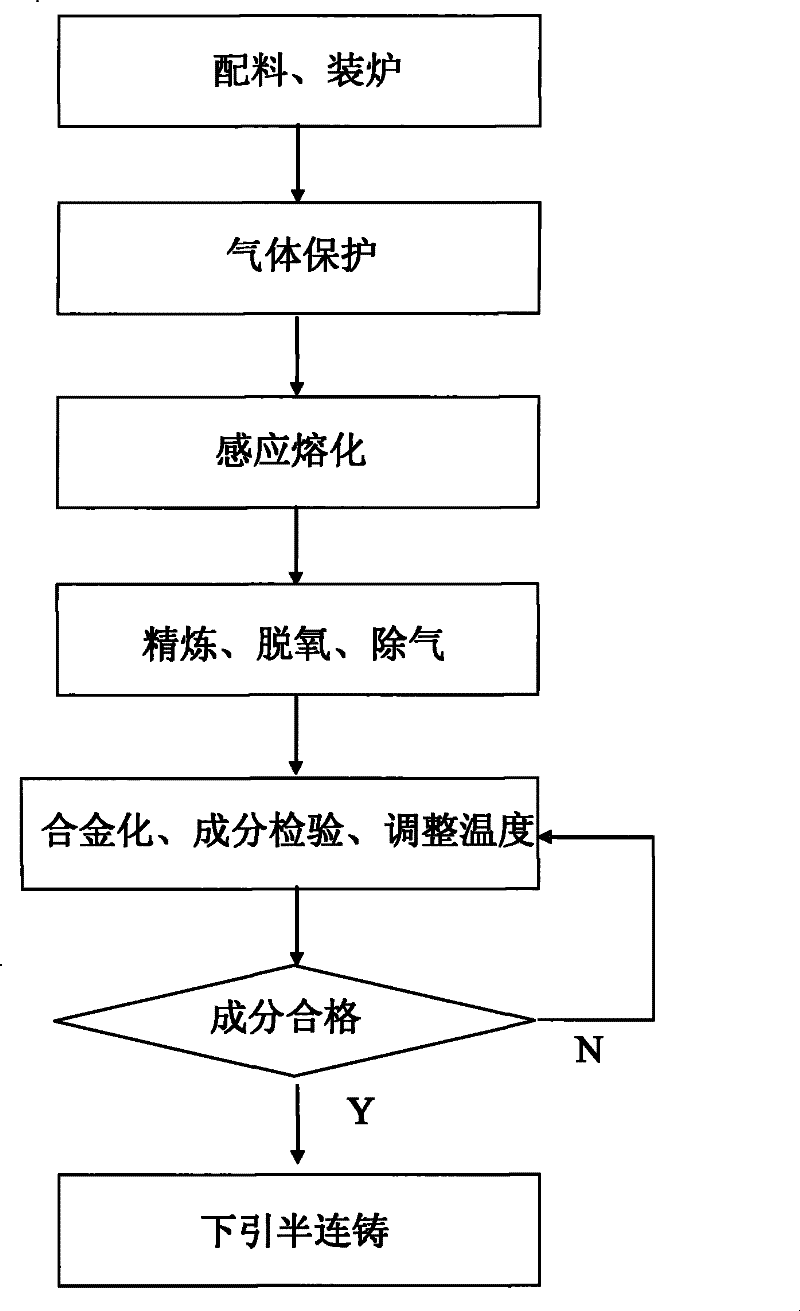

[0024] The non-vacuum melting and casting of Cu-Cr-Zr alloy slab is carried out by using the equipment of the present invention. The composition ratio is Cr: 0.45wt%, Zr: 0.15wt%, Mg: 0.05wt%, and the rest is copper, as shown in Table 1. The upper limits of burning loss are respectively: Cr: 10%, Zr: 15%, Mg: 20%, Cu: 2%.

[0025] First clean the furnace body, dry it, and confirm that the liquid flow control device is closed and the cooling water is working normally. Put the ingredients into the furnace, close the furnace cover, pass in the protective gas, and send electricity.

[0026] Gradually adjust the heating power of electricity transmission, observe the melting condition of the melt, after all the ingredients are melted, adjust the power and enter the refining stage. Deoxidize, degas and alloy. When the alloy composition needs to be strictly controlled, samples are taken from the feeding window of the furnace cover, and the composition is quickly inspected by direct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com