Multi-color chromaticity multi-stock trough composite slasher and technological process thereof

A technology for sizing machines and sizing tanks, which is applied to textile processing machine accessories, liquid/gas/steam yarn/filament processing, textiles and papermaking, etc. It can solve the problems of high sizing cost, fuzziness, scrapping, etc., and achieve improvement Effects of sizing efficiency and sizing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

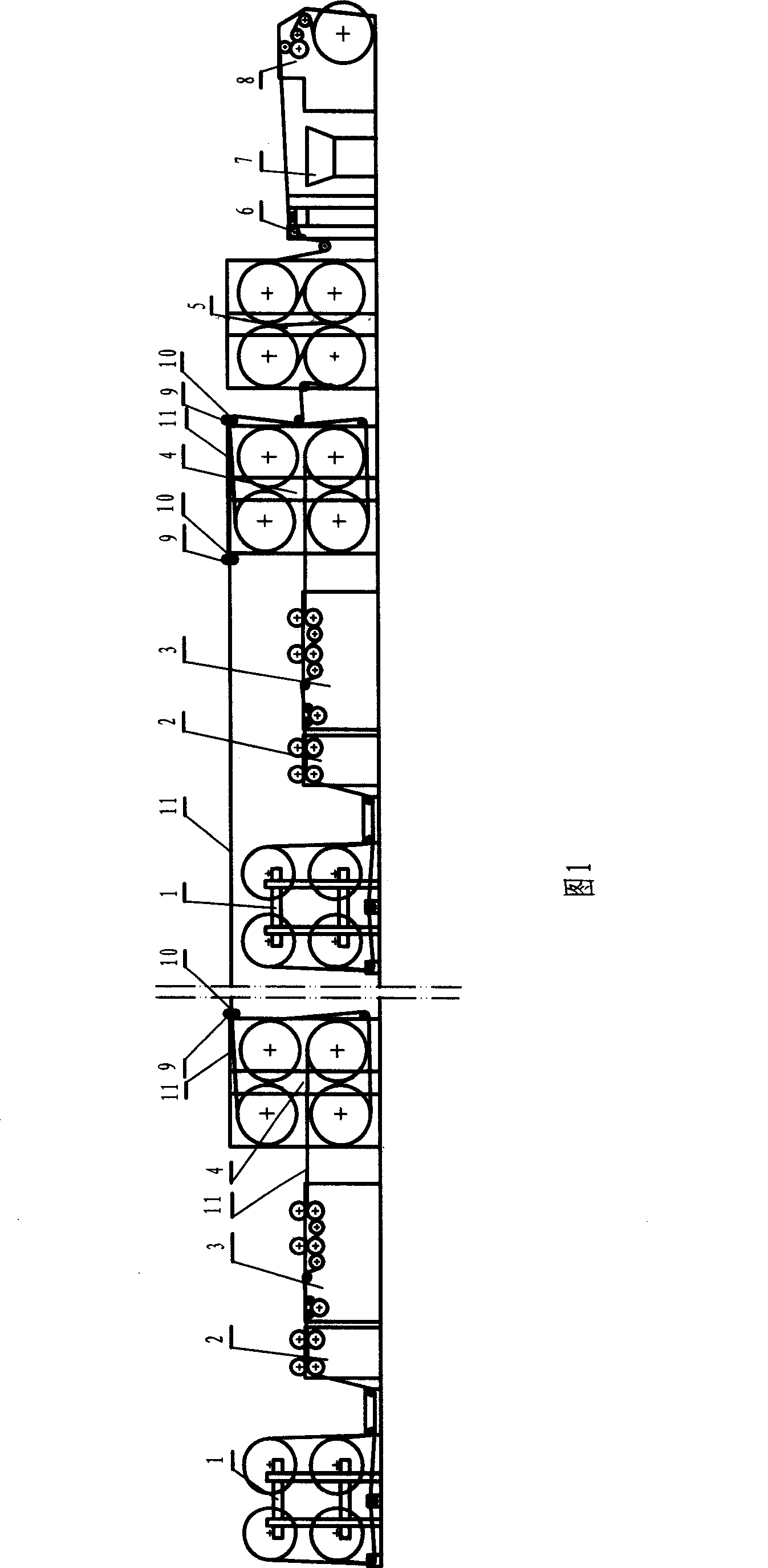

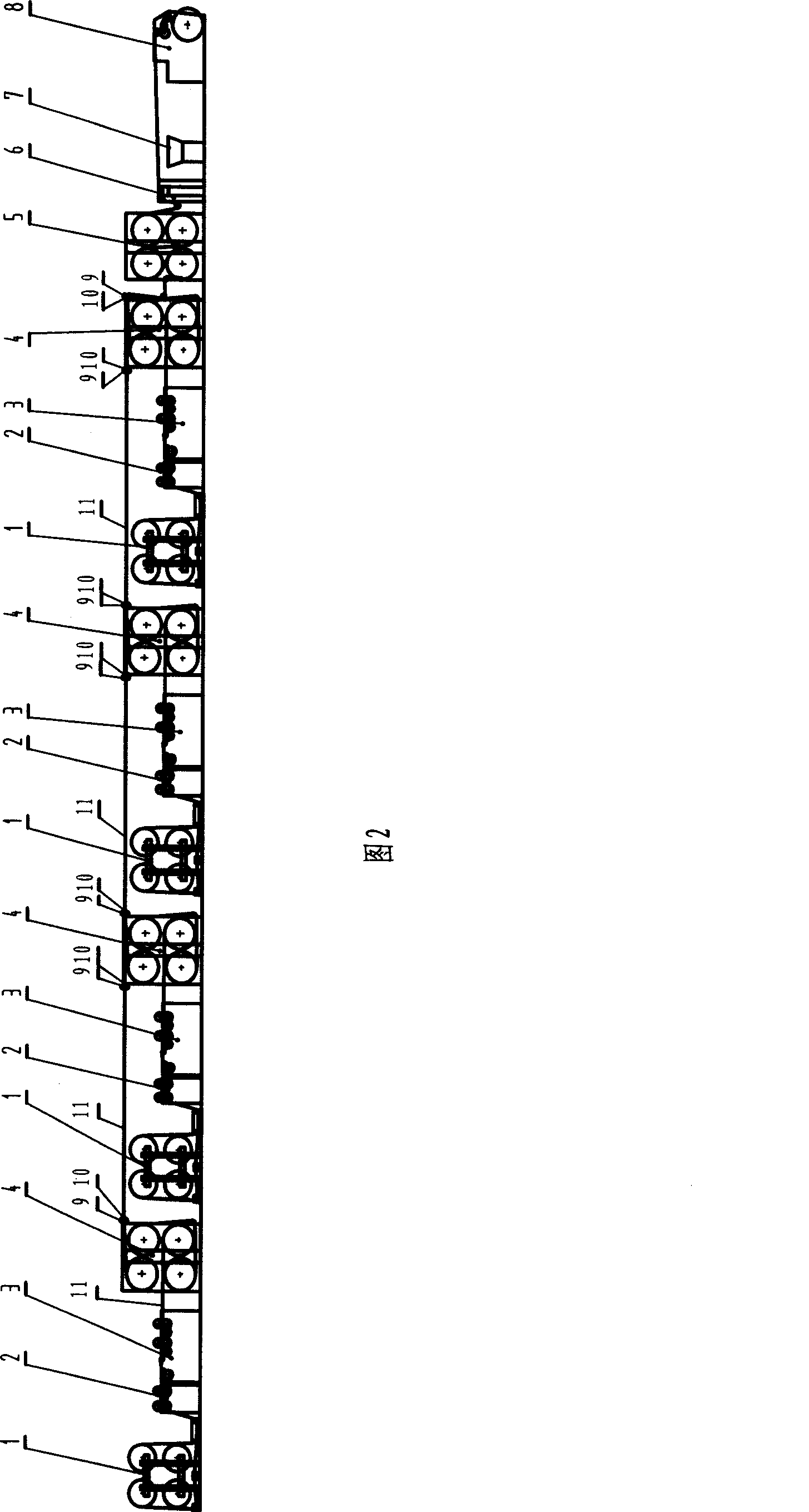

[0017] Describe the present invention in detail below in conjunction with accompanying drawing:

[0018] As shown in Figure 1, the public area is composed of a drying room 5, a wax tank 6, an automatic humidifying device 7 in the dry area, and a winding head 8; the sizing area is composed of a beam frame 1, a pre-wet tank 2, a slurry tank The drying room is composed of 4; after the public area, it is equipped with multiple sizing areas; the control part adopts the existing technology to implement closed-loop control on the servo motor. That is, a rotary encoder is installed at the tail end of the main shaft of the power transmission motor equipped on each transmission unit to be connected to the PLC and controlled by a computer. It not only detects the speed of the motor rotor, but also detects the phase of the motor rotor. The combination of the two controls the elongation during the entire driving process to keep constant, and the control accuracy can reach one ten thousandt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com