Preparing process of starch textile sizing agent

A textile slurry and preparation technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve problems such as poor color, hard size film, and small elongation, so as to reduce wastewater treatment costs, reduce sizing costs, and improve reliability. weaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

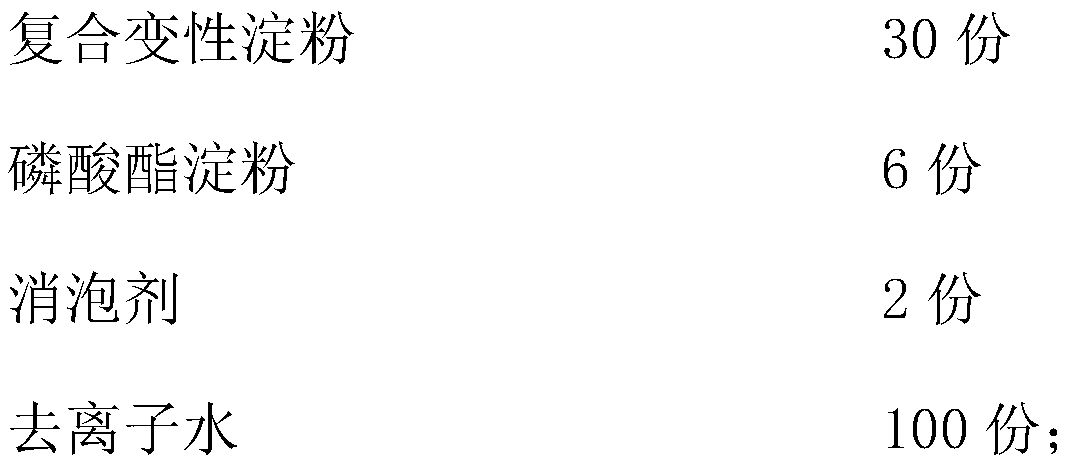

[0031] A kind of preparation technology of starch textile size, described size is prepared by following raw material by weight:

[0032]

[0033] The composite modified starch is prepared by the following method:

[0034] (1) Accurately weigh a certain amount of starch, dissolve it in water containing sodium sulfate and calcium oxide powder, and make starch milk with a concentration of 40%;

[0035] (2) When heating to 50°C, add an appropriate amount of maleic anhydride 5% solution, then adjust the pH of the reaction system to 10-11 with 3% NaOH solution, and stir for 6 hours while keeping the temperature of the reaction system constant;

[0036] (3) When the reaction finishes, neutralize the pH to 8.5 with dilute HCl solution, subsequently, add sodium hypochlorite in the reaction system, maintain the pH value of the system at 8.5-9 with 3% sodium hydroxide solution in the reaction process, keep the temperature of the system ;

[0037] (4) Continue to react for 6 hours, n...

Embodiment 2

[0044] A kind of preparation technology of starch textile size, described size is prepared by following raw material by weight:

[0045]

[0046] The composite modified starch is prepared by the following method:

[0047] (1) Accurately weigh a certain amount of starch, dissolve it in water containing sodium sulfate and calcium oxide powder, and make starch milk with a concentration of 40%;

[0048] (2) When heating to 50°C, add an appropriate amount of maleic anhydride 5% solution, then adjust the pH of the reaction system to 10-11 with 3% NaOH solution, and stir for 6 hours while keeping the temperature of the reaction system constant;

[0049] (3) When the reaction finishes, neutralize the pH to 8.5 with dilute HCl solution, subsequently, add sodium hypochlorite in the reaction system, maintain the pH value of the system at 8.5-9 with 3% sodium hydroxide solution in the reaction process, keep the temperature of the system ;

[0050] (4) Continue to react for 6 hours. W...

Embodiment 3

[0057] A kind of preparation technology of starch textile size, described size is prepared by following raw material by weight:

[0058]

[0059] The composite modified starch is prepared by the following method:

[0060] (1) Accurately weigh a certain amount of starch, dissolve it in water containing sodium sulfate and calcium oxide powder, and make starch milk with a concentration of 40%;

[0061] (2) When heating to 50°C, add an appropriate amount of 5% maleic anhydride solution, then adjust the pH of the reaction system to 10-11 with 3% NaOH solution, and stir for 6 hours while keeping the temperature of the reaction system constant;

[0062](3) When the reaction finishes, neutralize the pH to 8.5 with dilute HCl solution, subsequently, add sodium hypochlorite in the reaction system, maintain the pH value of the system at 8.5-9 with 3% sodium hydroxide solution in the reaction process, keep the temperature of the system ;

[0063] (4) Continue to react for 6 hours, ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com