Spinning fiber sizing material

A technology for textile fibers and sizing materials, applied in the field of textile fibers, to achieve the effects of satisfying environmental protection, reducing sizing costs, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

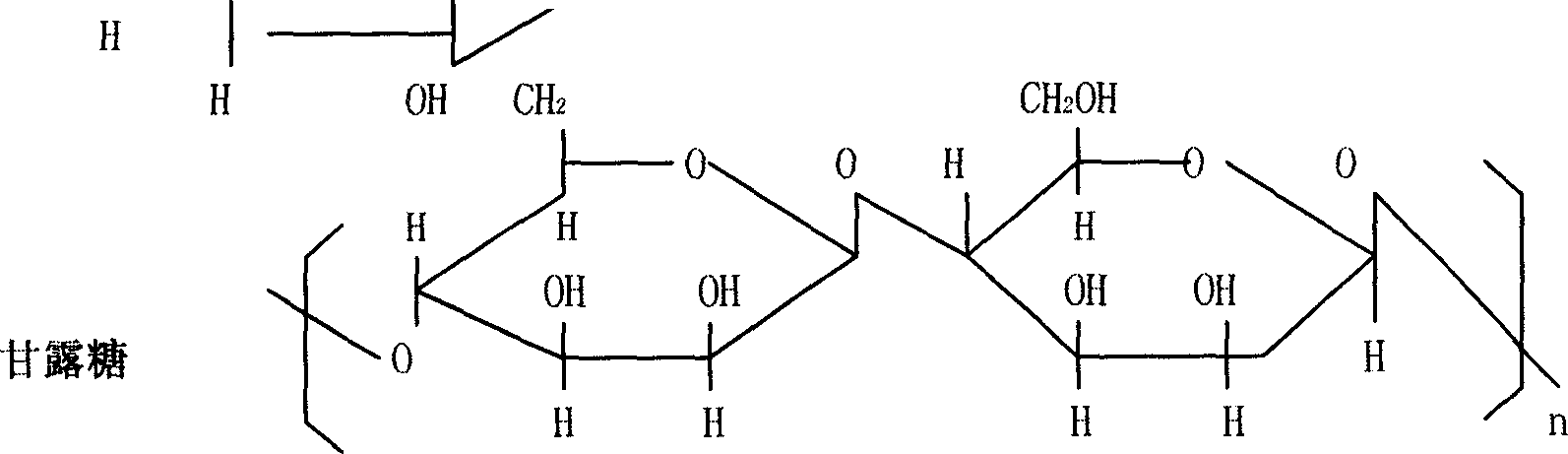

[0017] Preparation components: Guar gum modified into hydroxymethyl 5%, hydroxypropyl 3%, and cationic high molecular natural polymer 6%, modified tamarind fruit powder 3%, plant guar endosperm 6%, detoxified Ionized water 77%.

[0018] Implement the sizing test of replacing PVA with a high proportion of sizing yarn for testing, the details are as follows:

[0019] 1. Test species

[0020] T / C32+32.130.70.63" twill, its warp tightness is 81.2%, weft tightness is 43.7%, total tightness is 89.4%, and the raw material is polyester-cotton ratio 65:35. Difficulty, the main problem is: in the weaving process, the warp yarns are rubbed many times, it is easy to generate static electricity, the opening is easy to be unclear, the hairiness sticks, and defects such as yarn skipping and weft shrinkage appear on the cloth surface. To solve this problem, a More PVA is used to increase the size film coating and wear resistance, but the cost is high, and post-treatment desizing is difficul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com