Method and apparatus for detecting miniature bearing ferrule 45 degrees inner chamfer angle rapidly and accurately

A miniature bearing and chamfering technology, which is applied in angle/taper measurement and other directions, can solve the problems of poor coaxiality, inconsistency of machining reference and measurement, and inability to guarantee the coaxiality of the inner hole, so as to improve accuracy and detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

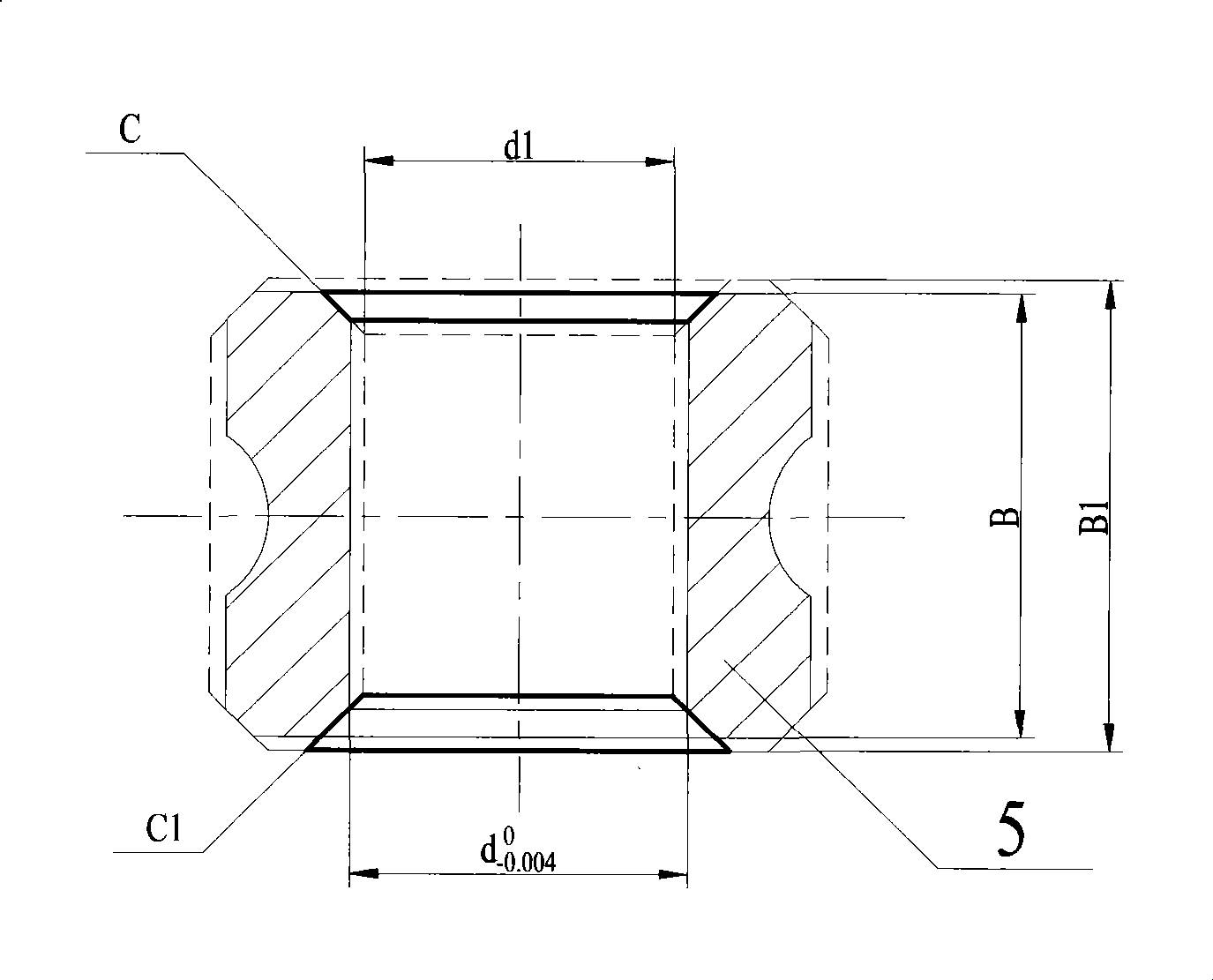

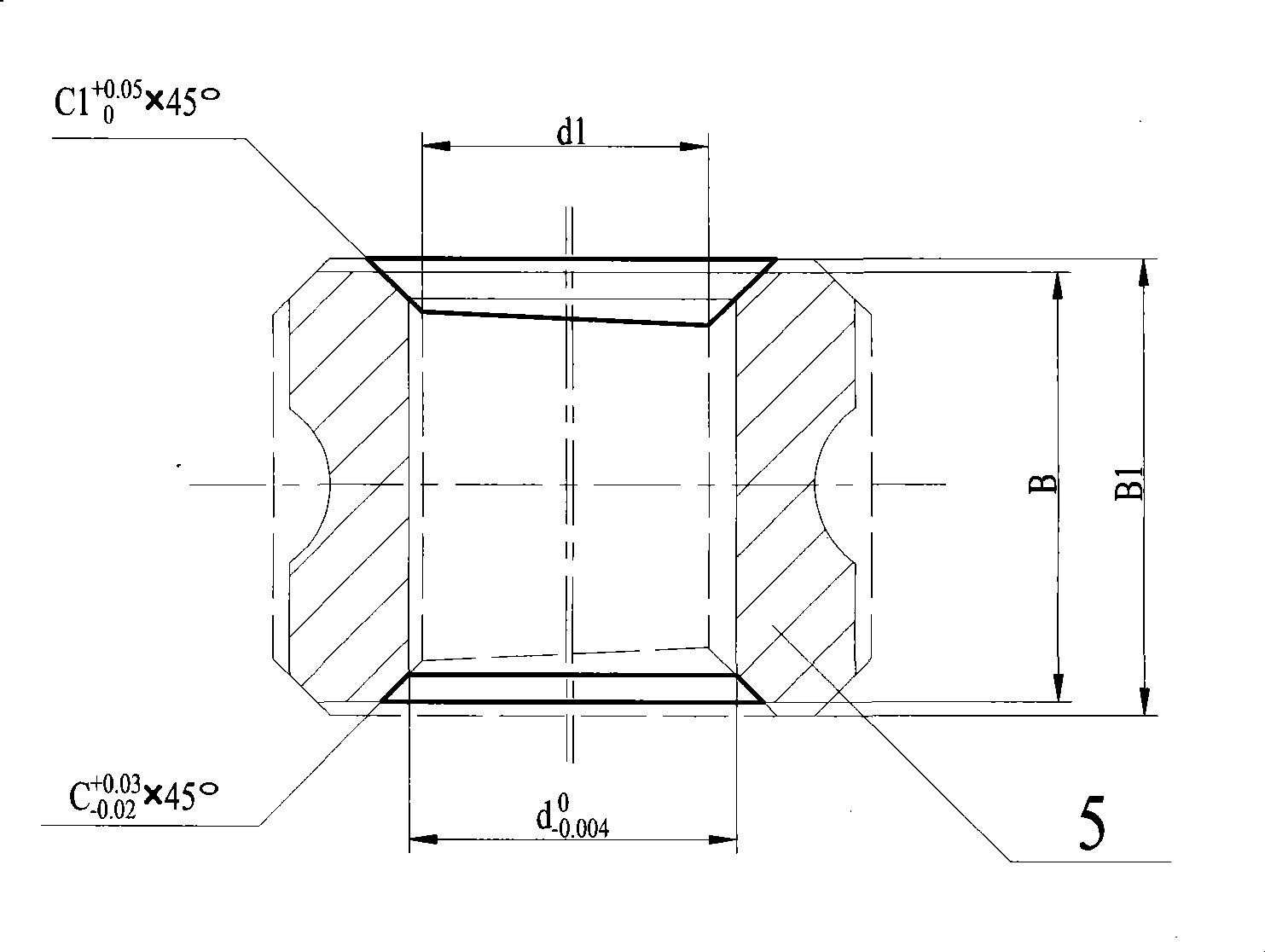

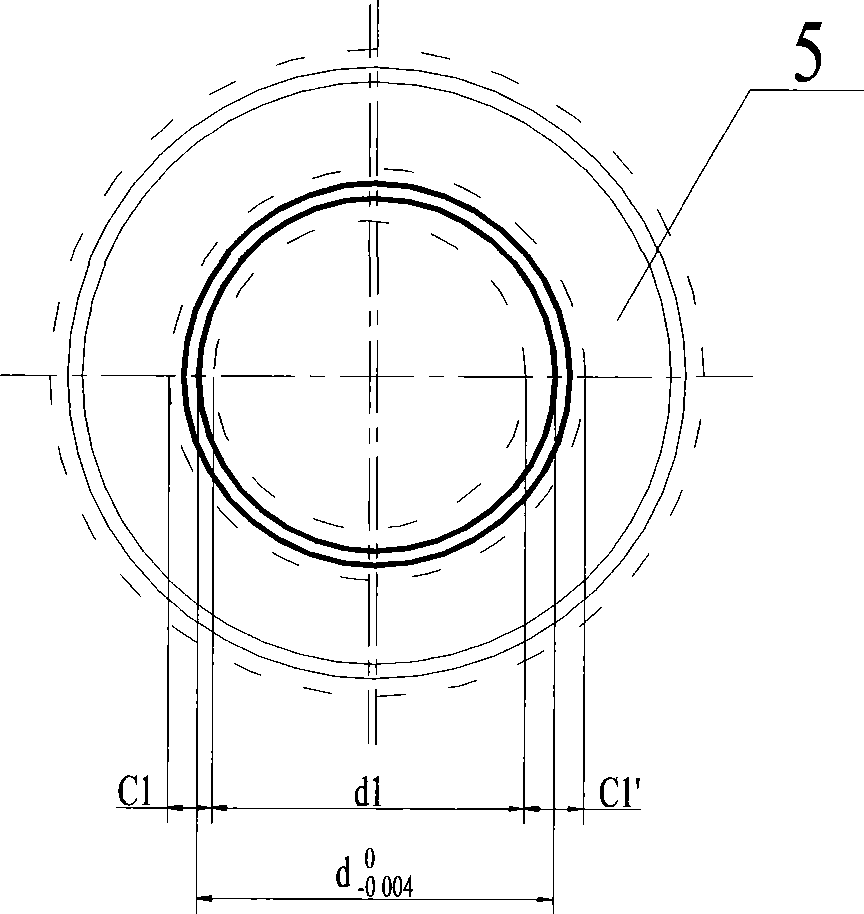

[0027] exist figure 1 , 2 , 3: The reference dimensions of a miniature bearing ring are as follows:

[0028] d=1.2mm; d 1 = 1.1mm; B = 1.6mm; B 1 = 1.7mm; C = 0.1mm; C 1 = 0.2 mm.

[0029] combine Figure 4 , 5 , the miniature bearing ring 45 ° internal chamfer fast and accurate detection device of the present invention consists of a base (1), a bracket (2), a dial indicator (3), a 90 ° measuring head (4), a standard part or an inner ring to be tested (5) Composition, fix a cantilever bracket (2) on the base (1), install a dial indicator (3) with a range of 0-5mm on the bracket (2), and install the dial indicator (3) after calibration The 90° measuring head (4), the standard part or the inner ring (5) to be tested is placed on the base (1) below the 90° measuring head (4), and the inner hole chamfer size of the standard part is 0.2×45°.

[0030] The fast and accurate detection method of the 45° internal chamfer of the miniature bearing ring of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com