A kind of spring support rigidity detection device

A detection device and stiffness technology, applied in the field of machinery, can solve the problems of insufficient detection accuracy of elastic hydrostatic support stiffness, and achieve the effects of facilitating movement, improving measurement accuracy and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

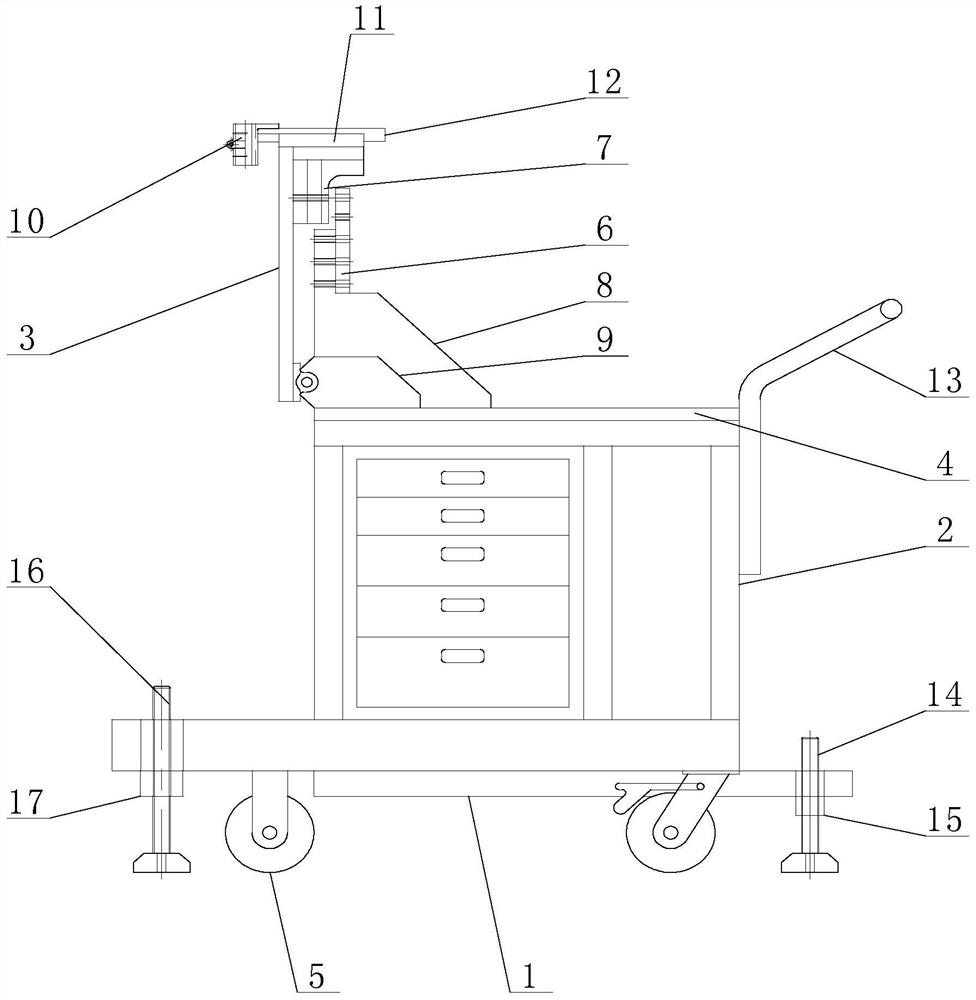

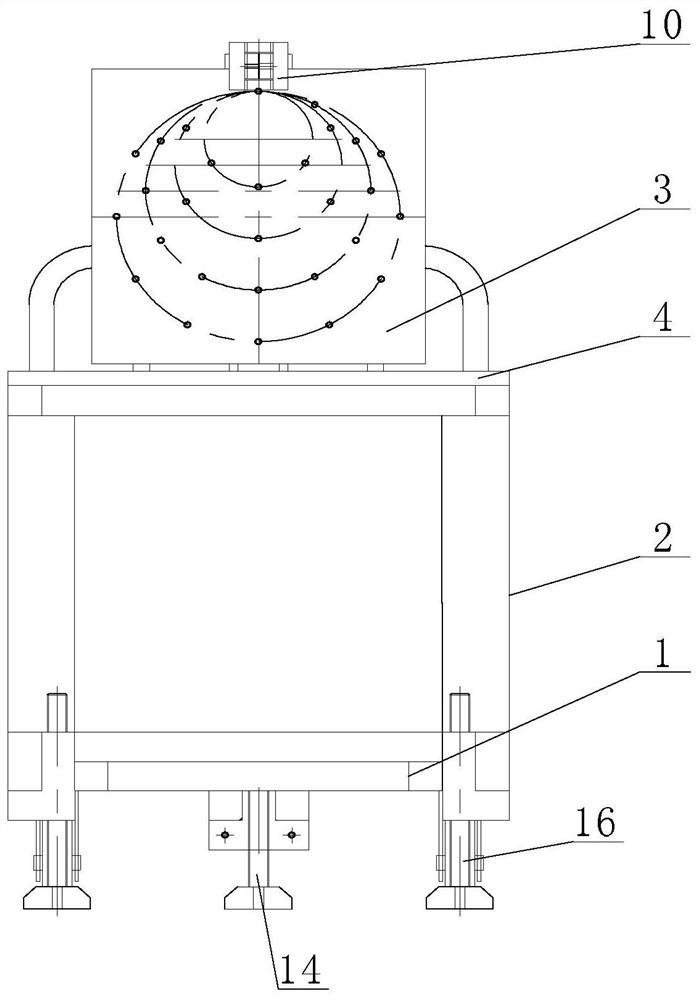

[0017] Embodiment 1: Combining figure 1 and figure 2 Describing this embodiment, a spring support stiffness detection device described in this embodiment includes a base frame 1, a frame 2, a fixed support mechanism, a detection and installation base plate 3, a table plate 4, a watch frame mechanism and four moving wheels 5. The four The moving wheels 5 are evenly installed on the lower surface of the base frame 1, the frame 2 is fixedly installed on the upper surface of the base frame 1, the platen 4 is horizontally installed on the frame 2, and the fixed support mechanism is installed on the upper surface of the platen 4 Above, the watch stand mechanism is mounted on the fixed support mechanism, the detection and installation substrate 3 is vertically arranged, and the lower end of the detection and installation substrate 3 is rotatably connected with the fixed support mechanism.

specific Embodiment approach 2

[0018] Specific implementation mode 2: Combining figure 1 and figure 2 Describing this embodiment, the fixed support mechanism of the elastic support stiffness detection device described in this embodiment includes an adjustment auxiliary plate 6, a support plate 7 and a fixed plate assembly, and the fixed plate assembly is installed on the front end of the upper surface of the table plate 4, The adjustment auxiliary plate 6 is installed on the fixing plate assembly, the support plate 7 is connected with the upper end of the adjustment auxiliary plate 6 , and the watch frame mechanism is installed on the support plate 7 . Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation three: combination figure 1 and figure 2 Describing this embodiment, the fixed plate assembly of the elastic support stiffness detection device described in this embodiment includes two fixed support plates 8 and two fixed side plates 9, and the two fixed support plates 8 are vertically and side by side fixedly installed on the At the front end of the upper surface of the table plate 4, two fixed side plates 9 are vertically installed side by side on the front end of the upper surface of the table plate 4, and the two fixed support plates 8 are located between the two fixed side plates 9. The fixed support plates 8 and Both the fixed side plates 9 are rotatably connected with the lower ends of the detection and installation base plate 3 , and the upper ends of the two fixed support plates 8 are fixedly connected with the adjustment auxiliary plate 6 . Other compositions and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com