Protection and control circuit for high-power HID lamp electric ballast

An electronic ballast and control circuit technology, applied in the direction of electric light sources, electrical components, lighting devices, etc., can solve the problems of large energy consumption and heavy pollution, and achieve the goal of overcoming internal conditions, reducing external conditions, and realizing protection and control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

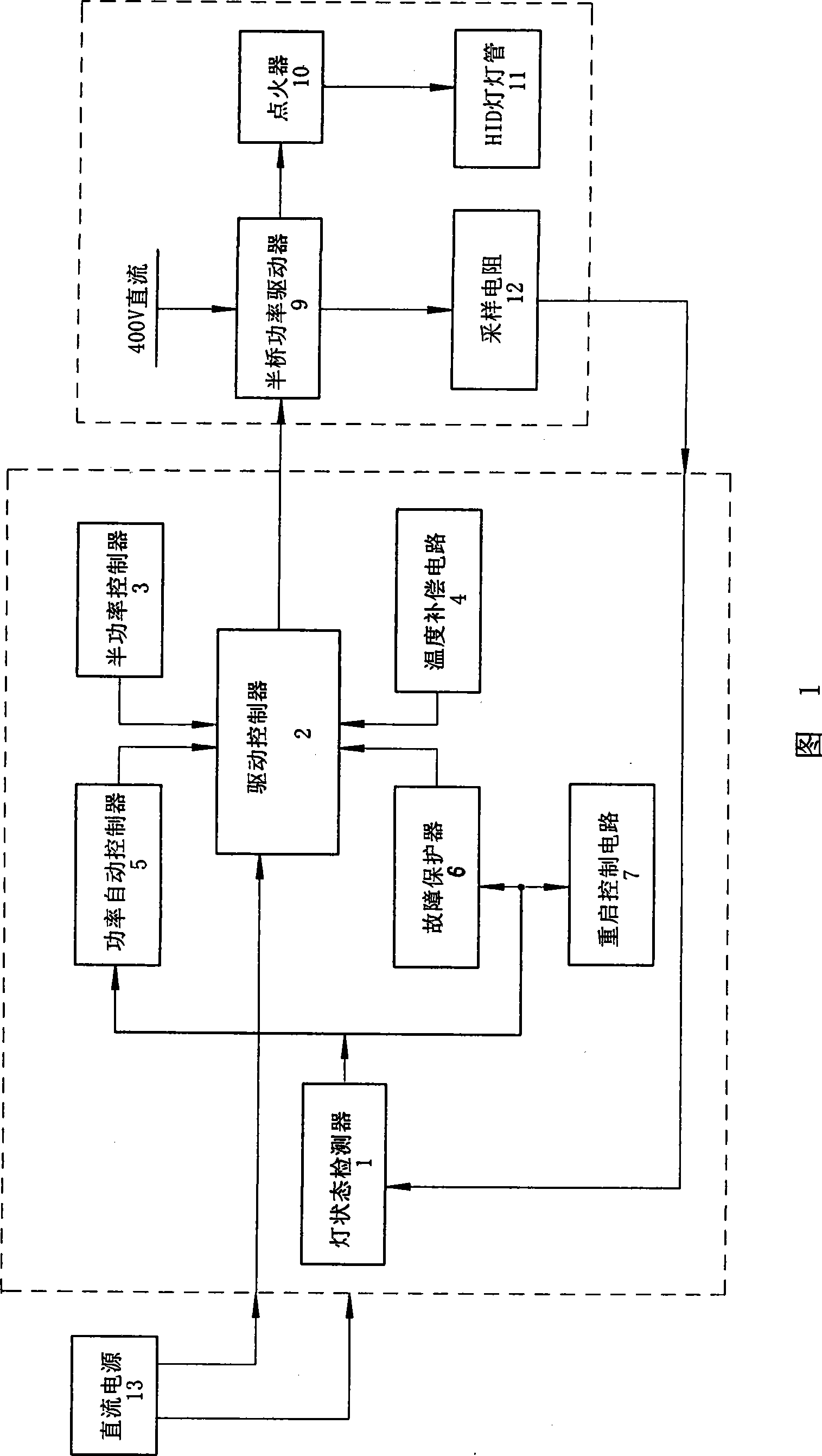

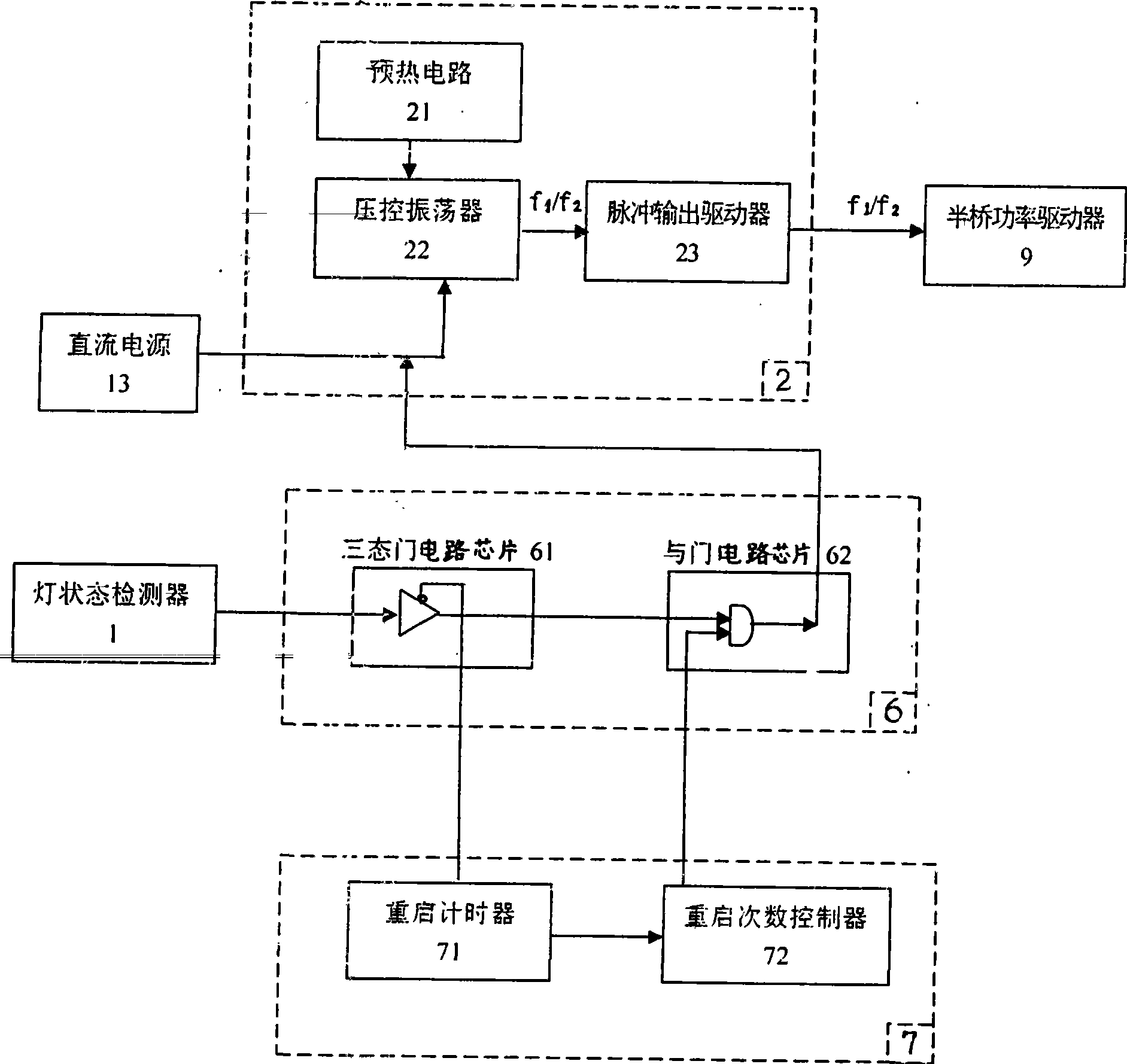

[0017] As shown in Figure 1, the protection and control circuit of the high-power HID lamp electronic ballast of the present invention is an integral part of the electronic ballast, and the protection and control circuit of the present invention includes a lamp state detector 1, a drive controller 2, Half-power controller 3, temperature compensation circuit 4, power automatic controller 5, fault protector 6 and restart controller 7 are composed of seven parts, wherein the input terminal of the lamp state detector 1 is connected to the sampling resistor 12 in the electronic ballast On, to receive the working status of the HID lamp; the two outputs of the lamp status detector 1, one is connected to the automatic power controller 5, and the lamp status signal is input to the automatic power controller, and the output of the automatic power controller 5 is connected to the drive controller 2 The input terminal of the lamp sends a power adjustment signal to the drive controller 2 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com