No-maintenance full-automatic filter

A kind of filter machine, fully automatic technology, applied in the direction of filtration separation, filtration circuit, fixed filter element filter, etc., can solve the problems of secondary pollution, large floor area, large engineering quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

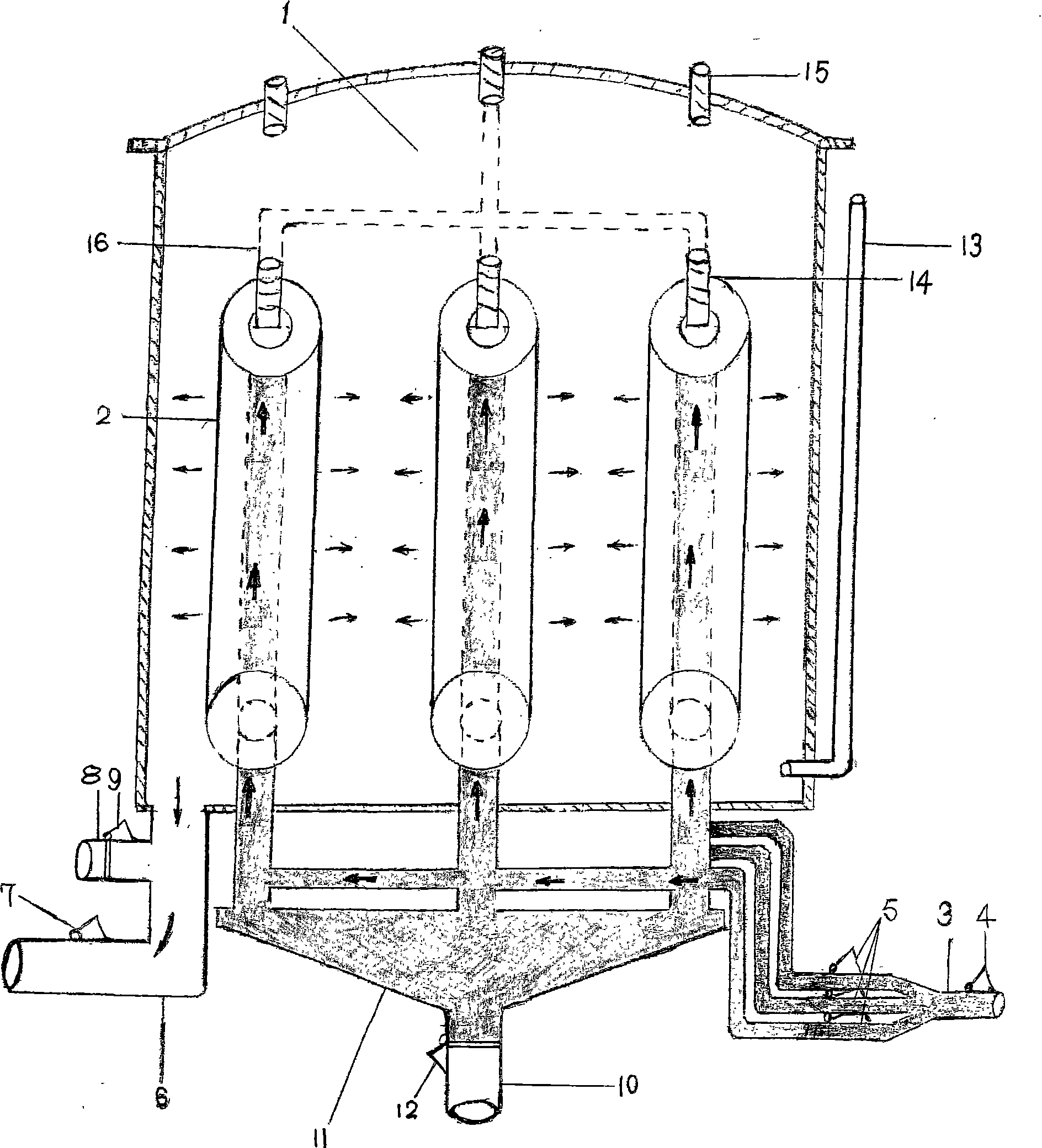

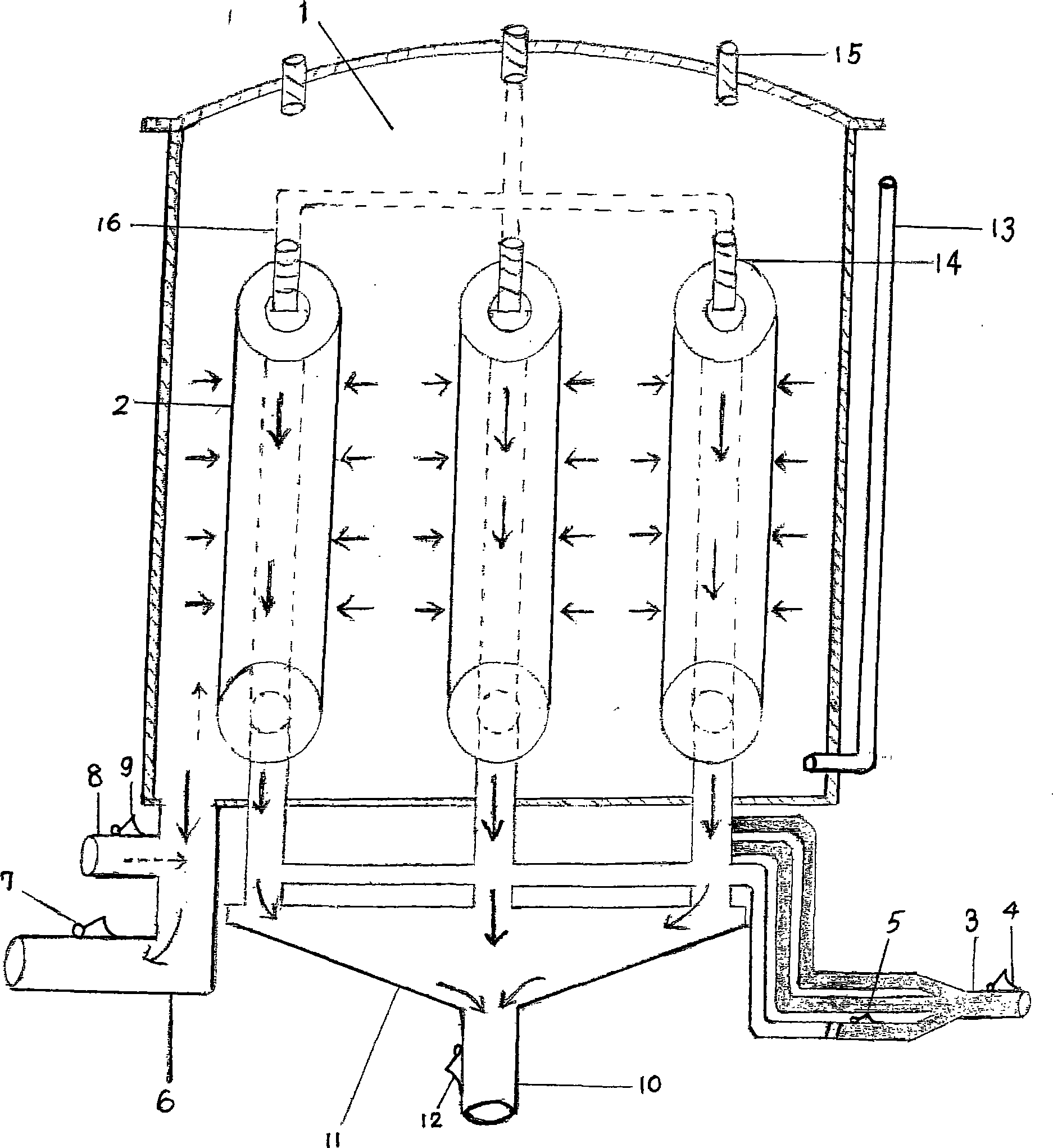

[0050] The structure and work flow of the filter of the present invention will be described in detail below in conjunction with the accompanying drawings.

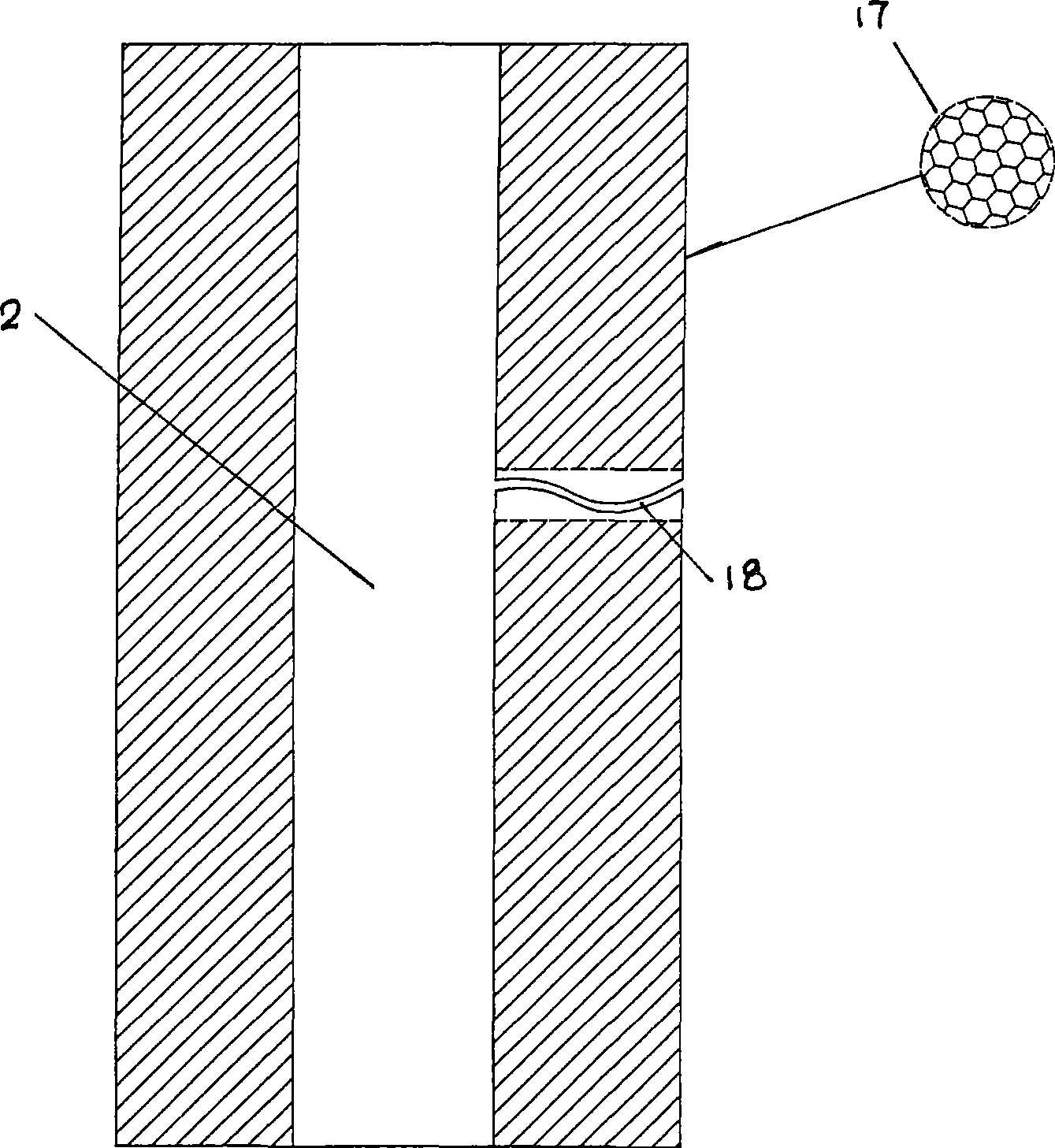

[0051] figure 1 It is a group of filtration units utilizing the filtration machine of the present invention to show the filtration process of the present invention. The filter of the present invention is composed of at least two groups of filter units as shown in the figure, and multiple groups of filter units can be connected in parallel or in series to form a filter suitable for various needs. The filter unit 1 includes one or more filter cores 2. In this embodiment, each filter unit includes 3 filter cores, and the whole filter machine includes 3 groups of filter units. The filter cores 2 are all placed in the closed casing of the filter.

[0052] The water inlet of the filter passes through the water inlet pipeline pressure divider 3 and is controlled by the electronic valve 4 . The water inlet pipeline pressure divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com