Gas-electric hybrid engine

An oil-electric hybrid power and engine technology, which is applied to the arrangement of multiple different prime movers, power plants, etc. Engine load, increased motor load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

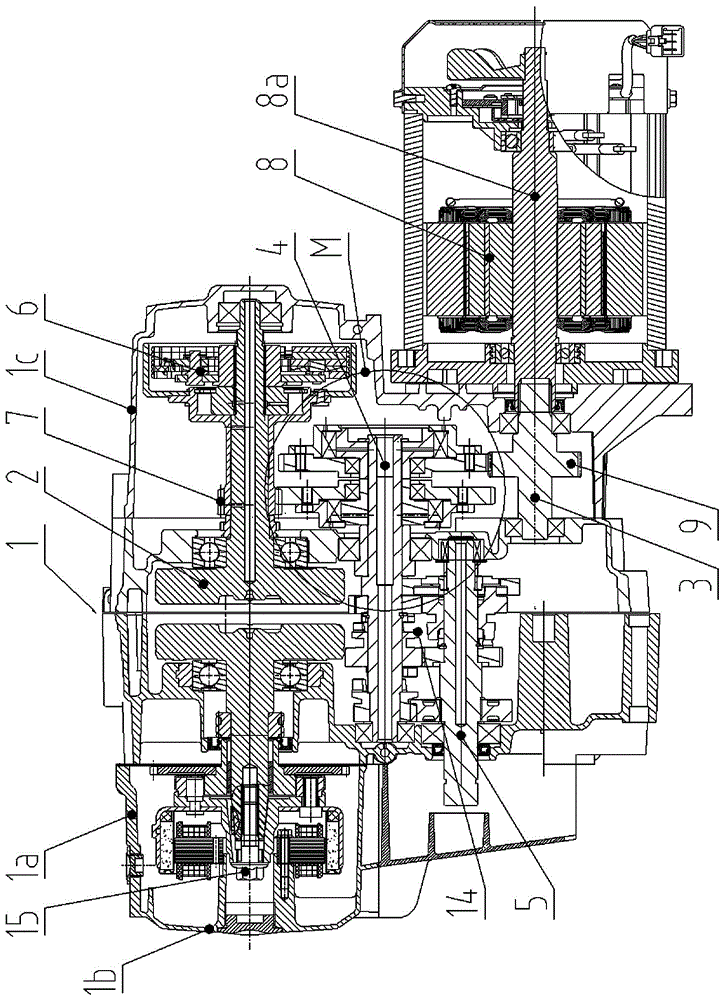

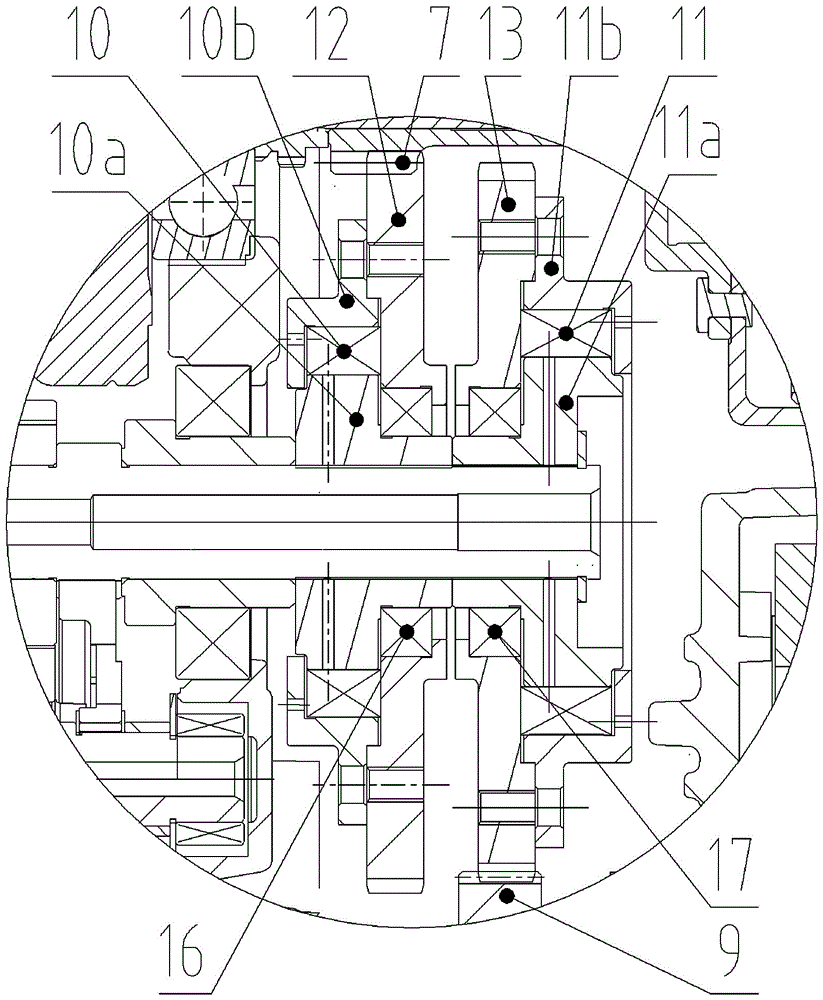

[0022] see figure 1 with figure 2, is a specific embodiment of a gasoline-electric hybrid engine. The gasoline-electric hybrid engine includes an engine casing 1, and the engine casing 1 includes a main casing 1a, a left cover 1b is provided on the left side of the main casing 1a, and a right cover 1c is provided on the right side of the main casing 1a. Described engine casing 1 is provided with crankshaft 2, motor transmission shaft 3, main shaft 4, countershaft 5, and crankshaft 2, motor transmission shaft 3, main shaft 4, countershaft 5 are all rotatably installed in main casing 1a by bearing , and parallel to each other, wherein, one end of the auxiliary shaft 5 also protrudes from the left cover 1b for external output power. The crankshaft 2 is driven and rotated by the piston rod of the internal combustion engine installed on the main casing 1a, the internal combustion engine is a gasoline engine, the crankshaft 2 is fixed with a clutch 6 in the circumferential direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com