Carrying command automatic generation system and method

An automatic generation and command technology, applied in the field of warehouse management system, can solve the problems of time-consuming and labor-intensive, prolonging the time required for warehouse inventory, low efficiency, etc., and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

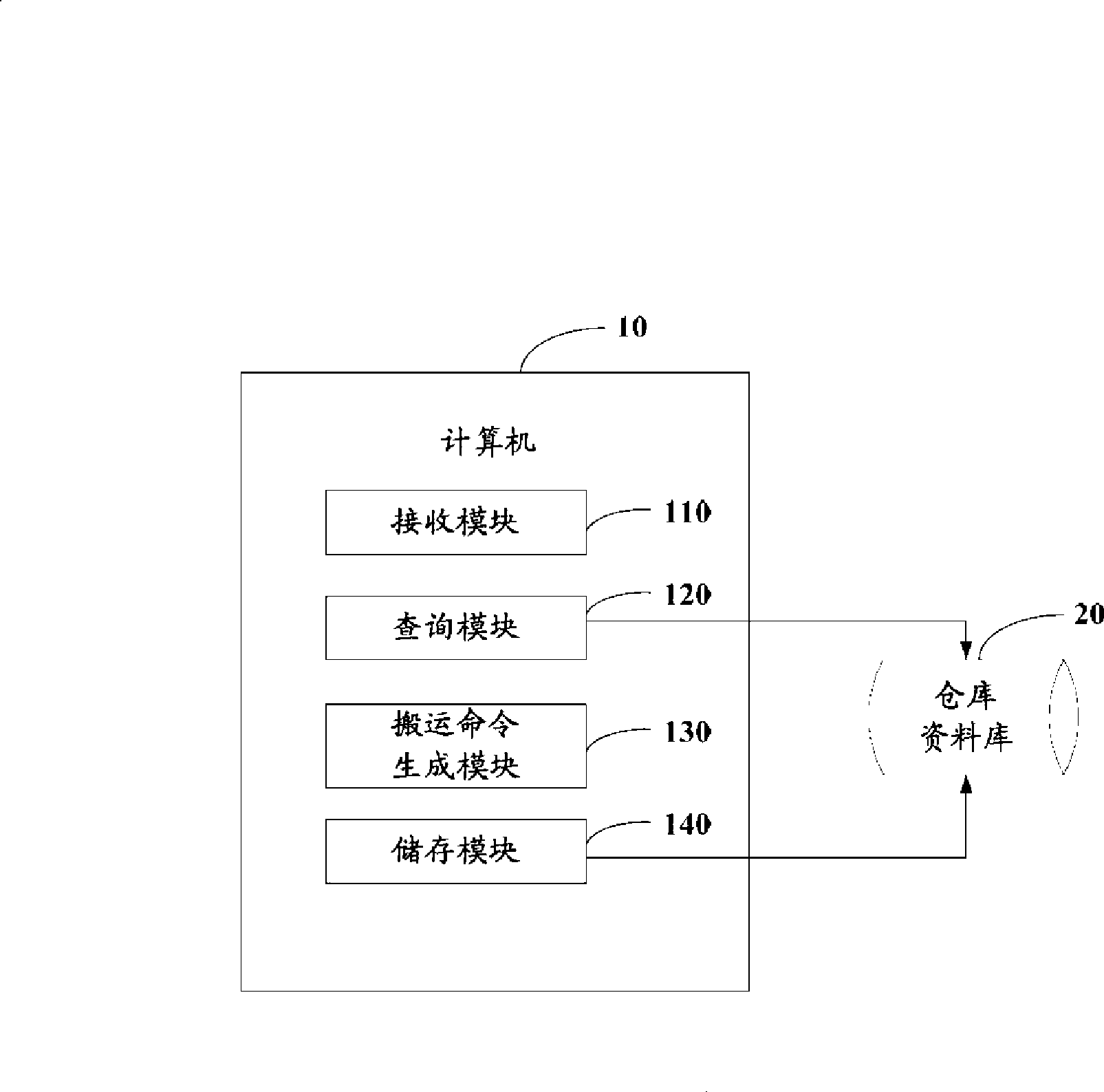

[0014] Such as figure 1 What is shown is a hardware architecture diagram of a preferred embodiment of the automatic inspection system for image files of the present invention. The system mainly includes a computer 10 and a warehouse database 20.

[0015] The warehouse database 20 is used to store information about the robot type of the warehouse and the current storage status information of the goods in the warehouse.

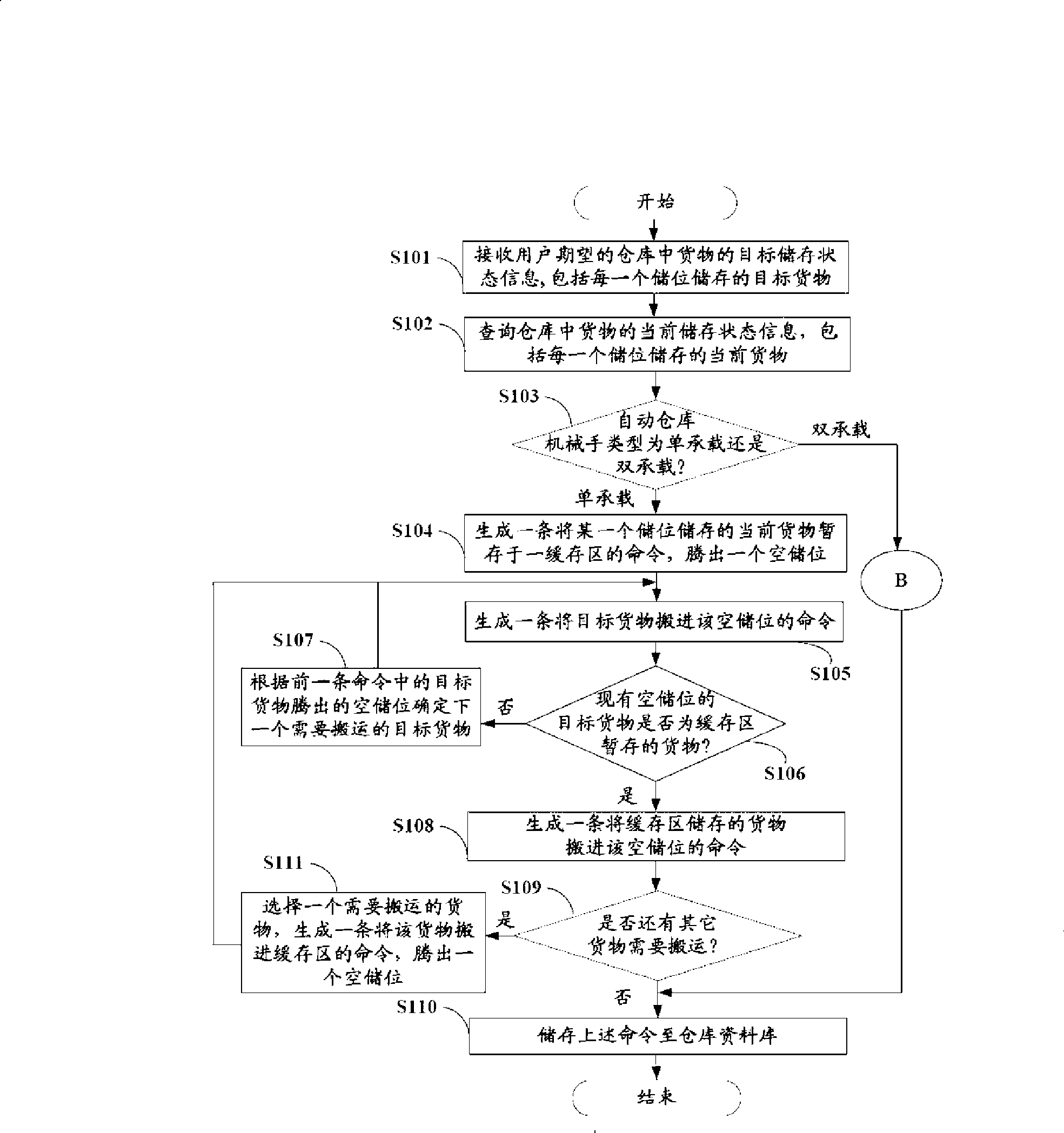

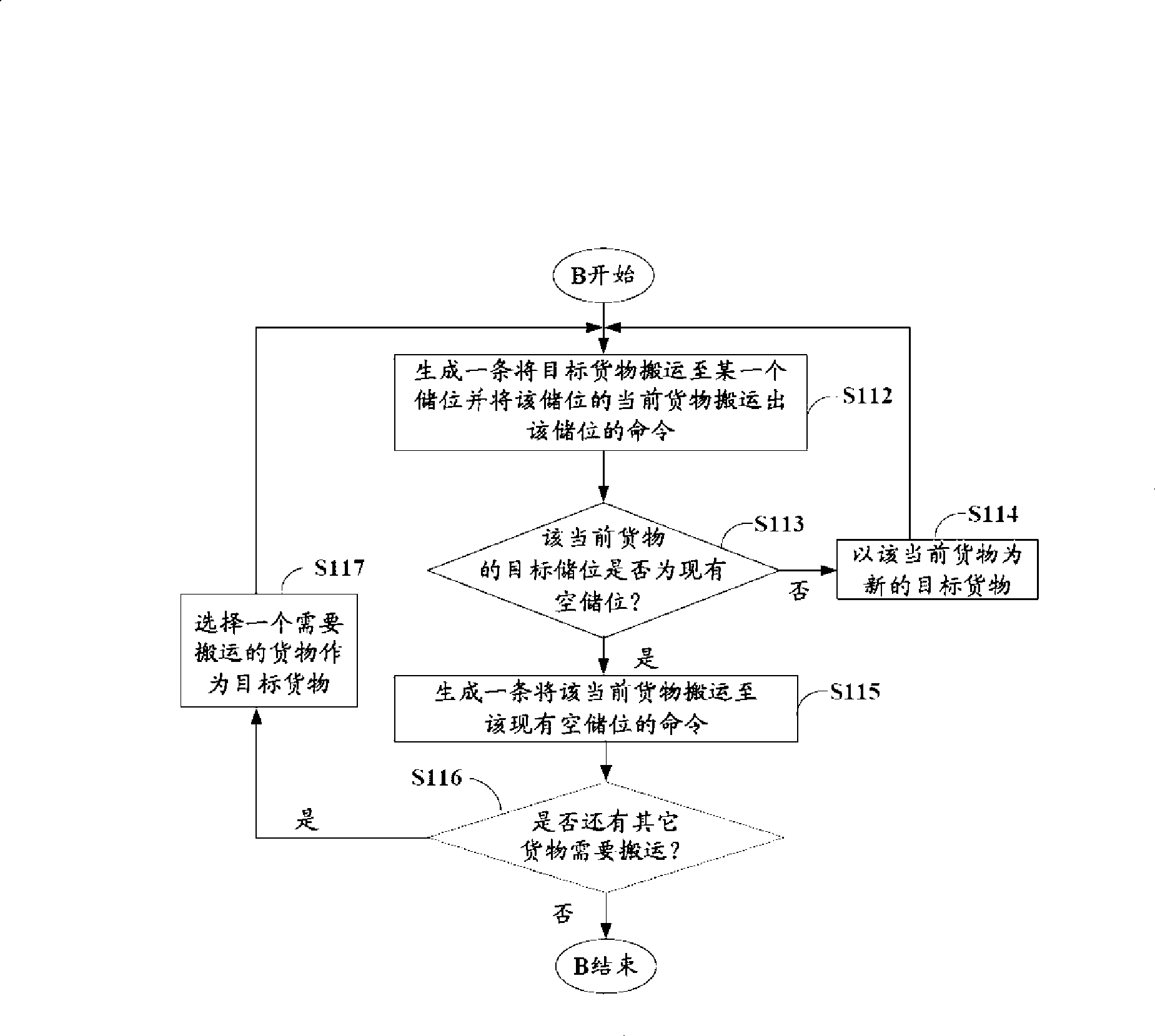

[0016] The manipulator type of the warehouse is generally single-carrying or dual-carrying. A single-carrying manipulator can only grab one cargo at a time, so you need to set up a buffer area when moving the cargo. When carrying out the handling operation, first move the current cargo in a certain storage location into the buffer area for temporary storage, and then move the target cargo in the storage location Enter the storage position. The dual-carrying manipulator can grab two goods at a time, and while moving the current goods in a certain storage position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com