Radiator assembly

A technology for radiators and components, applied in the direction of indirect heat exchangers, heat exchanger types, fixed conduit components, etc., can solve the problems that vibration cannot be fundamentally solved, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

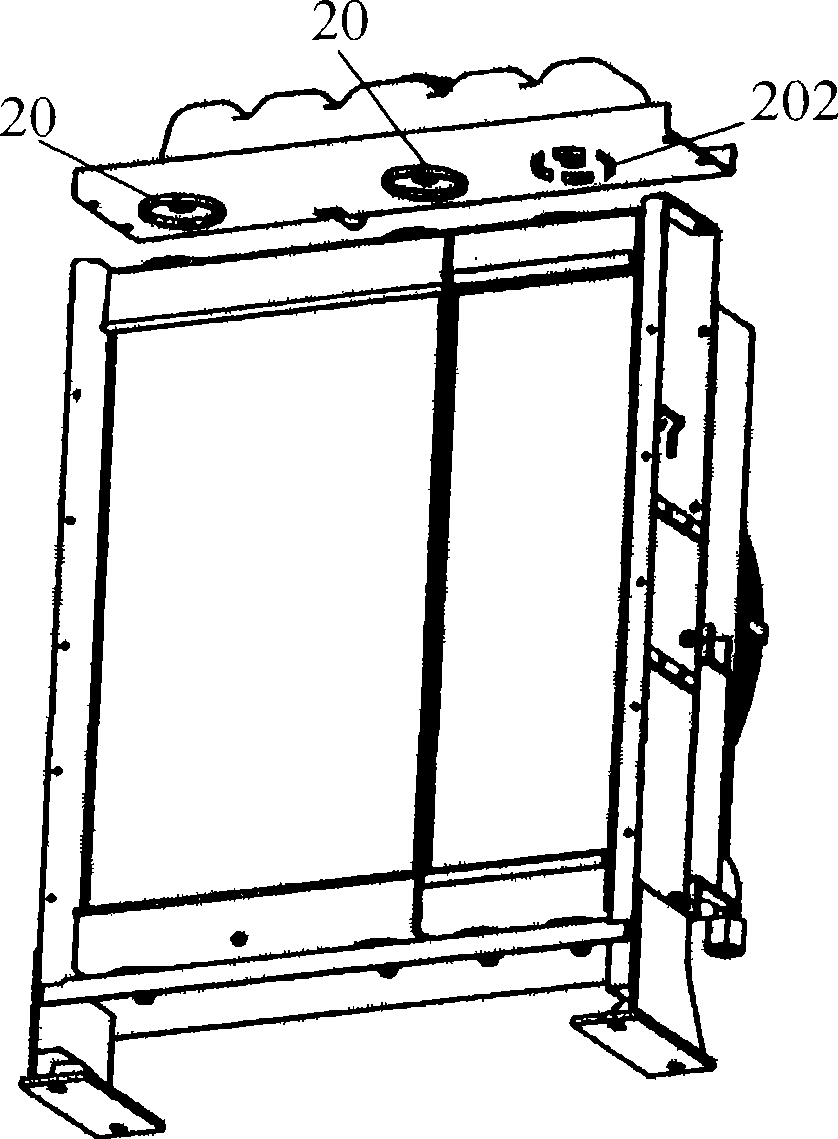

[0022] Hereinafter, embodiments of the assembly structure of the heat sink assembly of the present invention will be described with reference to the drawings. Please note that the term "retaining ring" in this application is not limited to a circular ring-shaped retaining ring, but also includes rings of other shapes such as rectangles.

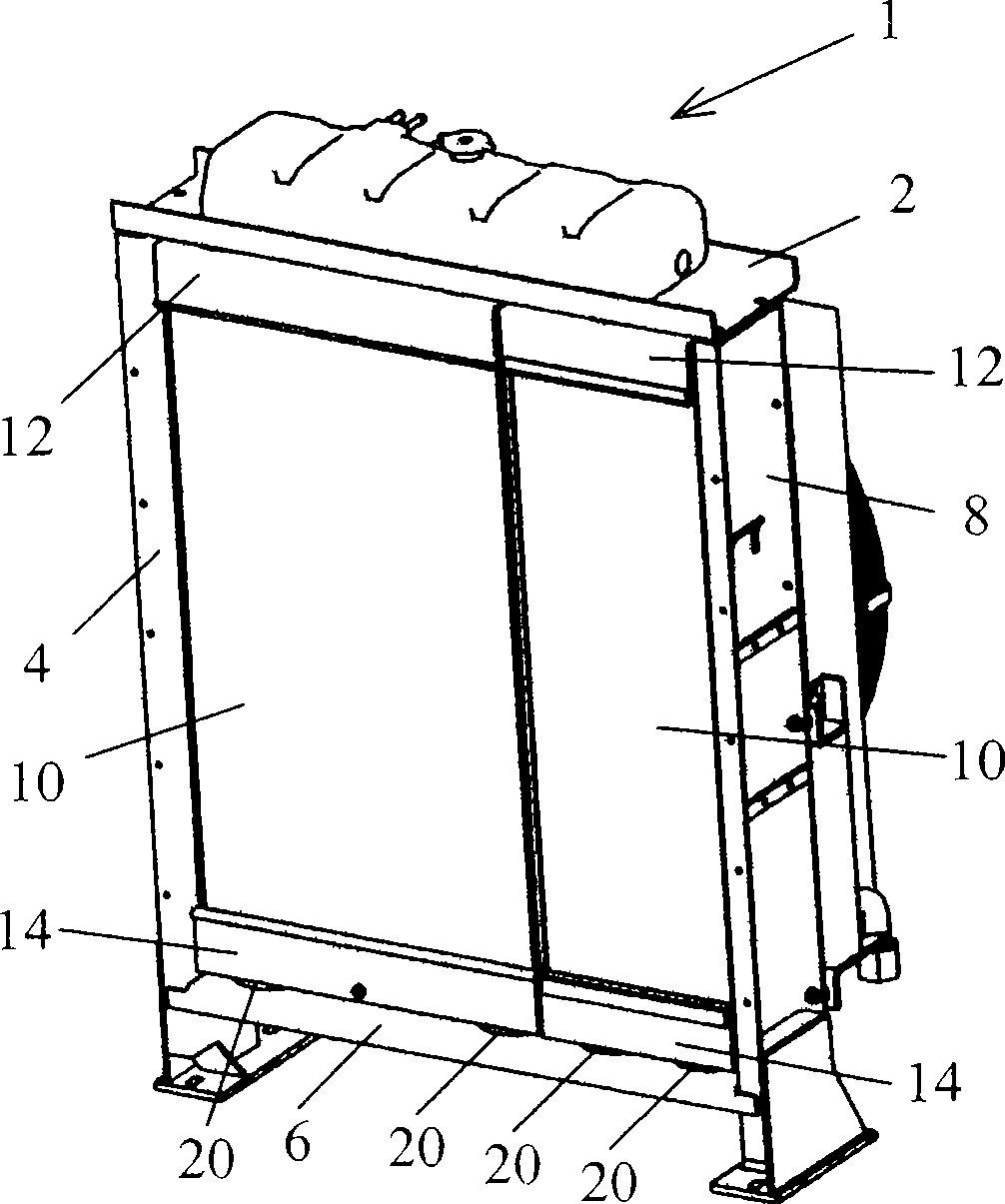

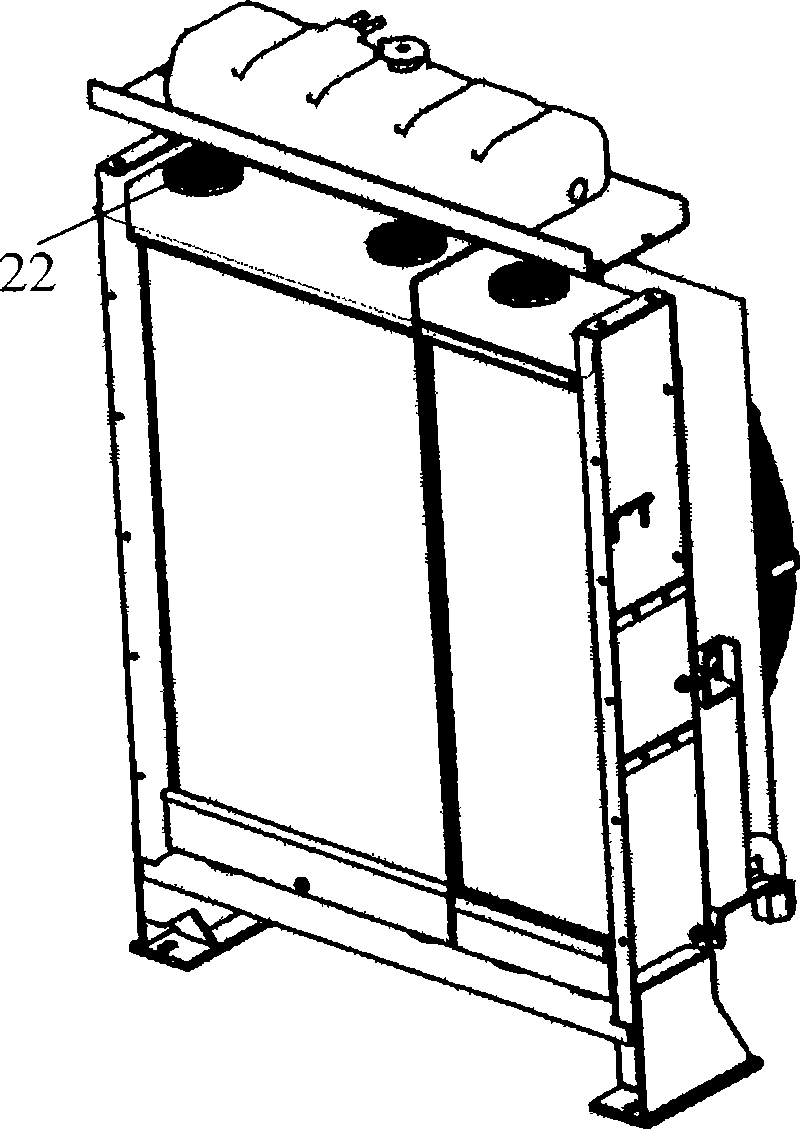

[0023] Such as figure 1 As shown, the radiator assembly 1 of the present invention includes a heat dissipation core 10 for heat dissipation, an upper liquid storage chamber 12 and a lower liquid storage chamber 14, and a radiator frame. The upper liquid storage chamber 12 and the lower liquid storage chamber 14 are respectively connected to the upper and lower ends of the heat dissipation core 10 by means such as welding, and are in fluid communication with the coolant flow passages in the heat dissipation core 10 to accumulate cooling water and cooling oil. Or other types of coolant. The radiator frame includes an upper frame plate 2, a lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com